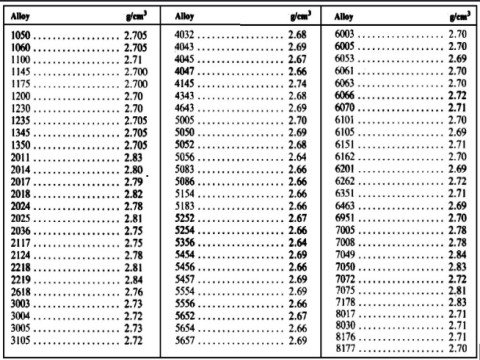

The Density of Aluminum & Aluminum Alloys is key for applications. Pure aluminum and common alloys have densities around 2.7 g/cm³.

Aluminum ranks among the most plentiful metallic elements residing in the earth’s crust, and its promise of low density, resistance to corrosion, and superb manufacturability has secured its place across sectors like aerospace, automotive, and construction.

When selecting a material, density stands out as a fundamental property, dictating suitability for specific applications.

Beginning with the density of unalloyed aluminum, we will chart the systematic trend in the density of aluminum alloys and unravel the connection between these density changes and the parameters of the die-casting process.

Density of Aluminum & Aluminum Alloys

Density of Pure Aluminum

Pure aluminum has a density of approximately 2.7 grams per cubic centimeter (g/cm³). This relatively low density makes aluminum an ideal choice for weight reduction, particularly in the automotive and aerospace sectors. Its lightweight properties contribute to improved fuel efficiency and overall equipment performance.

Density of Aluminum Alloys

Adding alloying elements like magnesium, silicon, and copper significantly improves aluminum’s mechanical properties and slightly changes its density. The density range of common aluminum alloys is as follows:

- 1xxx series (such as 1100): close to pure aluminum, about 2.71 g/cm³5.

- 2xxx series (such as 2024): after adding copper, the density increases slightly to 2.78 g/cm³5.

- 6xxx series (such as 6061): the addition of magnesium and silicon keeps the density at 2.7 g/cm³ while improving the strength11.

- 7xxx series (such as 7075): high zinc content increases the density to 2.81 g/cm³, but the strength can reach 572 MPa5.

- Special alloys (such as 8090): contain lithium elements, the density is as low as 2.54 g/cm³, suitable for aerospace5.

Influencing factors: the atomic weight of the alloying elements, the addition ratio and the heat treatment process will affect the density. For example, T6 heat treatment increases strength through precipitation strengthening but has little effect on density11.

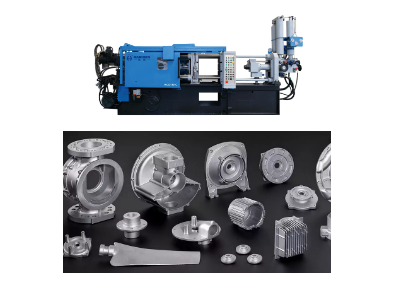

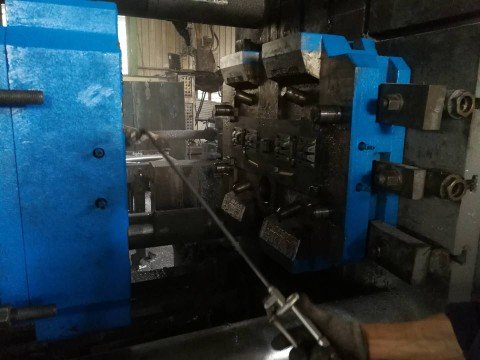

Relationship between die casting process and density

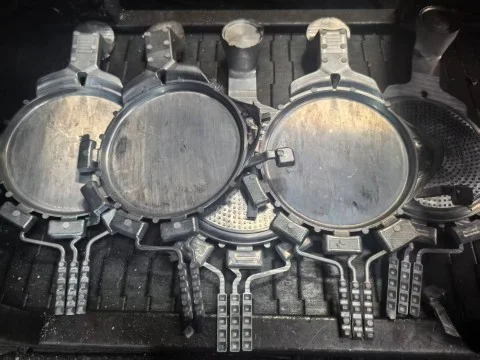

Die casting is a process for efficiently producing complex aluminum parts. During the process, molten aluminum is injected into a steel mold under high pressure and quickly cooled to form. The impact of this process on material density is reflected in two aspects:

- Porosity control: The high-pressure environment reduces the residual gas in the melt, improves the density of the material, and thus improves the mechanical properties6.

- Alloy selection: Die casting commonly uses alloys with good fluidity (such as A380, ADC-12), with a density of about 2.7-2.8 g/cm³, taking into account both molding efficiency and strength6.

- Limitations: Tiny pores may remain inside the die casting, so T6 heat treatment is usually not performed (to avoid surface defects caused by gas expansion)

Application advantages of die casting

- High precision: complex parts with uniform wall thickness can be produced with a tolerance of ±0.1 mm6.

- Fast mass production: the mold can be reused, suitable for large-volume needs such as automotive parts and electronic housings614.

- Cost-effectiveness: compared with sand casting, die casting has a high surface finish and reduces subsequent processing steps

HAICHEN Cold Chamber Die Casting Machines

Precision Injection Systems

HAICHEN’s cold chamber die casting machines are equipped with precision injection systems that are optimized for low – density materials like aluminum. These systems ensure precise control over injection speed and pressure, resulting in high – quality parts with intricate details and tight tolerances.

Advanced Temperature Control

Our machines feature advanced temperature control systems that maintain optimal melting and injection conditions for aluminum alloys. This ensures consistent material flow and reduces the risk of defects, enhancing part quality and production efficiency.

High – Performance Molds

HAICHEN provides high – performance molds designed to handle the low – density characteristics of aluminum. These molds are engineered to ensure efficient metal flow and rapid cooling, producing high – quality parts with complex geometries.

Energy Efficiency

Our cold – chamber die – casting machines are designed to be energy – efficient, making them ideal for handling low – density materials like aluminum. By optimizing the casting process, HAICHEN machines reduce energy consumption and lower production costs.

HAICHEN: Die Casting Practice Based on Aluminum Alloy Density

HAICHEN focuses on matching process parameters with the density of aluminum alloys in die casting. We provide different process solutions for alloys of various densities to ensure product quality and performance.

Case Study: Producing Lightweight Auto Parts with Low-Density Alloy

An auto parts maker needed extreme weight reduction. They switched a structural part from standard A380 alloy (density ~2.7 g/cm³) to a lithium-containing 8090 series alloy (density ~2.54 g/cm³). This low-density alloy had different flow and solidification behavior, causing filling issues and low strength with the old process.

- HAICHEN Solution:

- Process Adjustment: We recalibrated the injection curve on the HAICHEN machine for the low-density alloy. We increased the injection speed and pressure to ensure complete filling before rapid solidification.

- Temperature Management: We optimized the mold temperature, using a higher setting to improve alloy flow and stronger local cooling to refine the grain structure and maintain strength.

- Process Monitoring: We used the machine’s real-time monitoring to track filling time and internal quality data, stabilizing the process window.

- Result: The part achieved about 6% weight reduction while meeting all strength requirements. Production efficiency remained stable. This case shows how HAICHEN’s precise process control helps customers successfully use special-density materials for product innovation.

Die-casting machine manufacturer: HAICHEN

As China’s leading die-casting equipment manufacturer, HAICHEN focuses on the research and development and production of high-performance die-casting machines.

Our company offers a wide range of die casting machines, including cold chamber and hot chamber models, to meet different production needs.

Haichen also provides comprehensive after-sales services, including technical support, spare parts supply and training, to ensure that customers get the most from their investment.

Density of Aluminum & Aluminum Alloys are closely related to their composition and process. Die casting technology further expands the application boundaries of aluminum alloys by optimizing material fluidity and molding efficiency. Choosing a professional equipment manufacturer can ensure the dual improvement of product quality and production efficiency.