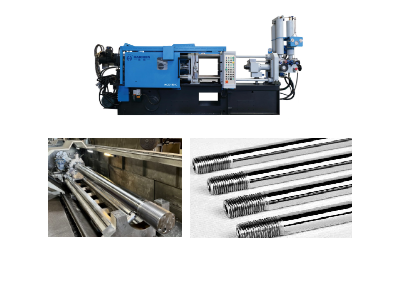

Die cast machine tie bar is critical components that maintain the structural integrity of the machine during the high-pressure die casting process.

Over time, tie bars can experience wear, stretching, or damage due to the extreme forces and thermal cycling they endure. Repairing and machining tie bars is a specialized process that requires precision and expertise.

For die casting machine tie bar repair and machining mainly includes these basic steps.We need to initial inspection to check and evaluate damage severity through visual inspection, non-destructive testing, and dimensional measurement. Then to determine what is the repair method. Small, non-penetrating cracks may be repaired by welding. And for severe damage warrants replacement.

Role and Importance of die cast machine tie bars

- Principle

- function

- material

- importance

Principle

The tie bar is a critical component in a die-casting machine, used to maintain the closure of the mold.

Function

Its primary function is to apply pressure to ensure that the mold does not separate during the high-pressure injection process.

Material

Tie bars are typically made of high-strength steel and are operated by heavy-duty mechanical arms.

Importance

During the die-casting process, tie bars are subjected to significant mechanical stress, so their condition directly affects the quality of the die-cast parts and production efficiency.

Common Issues and Repairs of die cast machine tie bars

- Inspection and Assessment

- Surface Treatment

- Replacement or Repair of Critical Components

Over time, the die casting machine tie bars may experience wear, corrosion, or even breakage. These issues can lead to misalignment of the mold, deformation of die-cast parts, or production interruptions. To address these problems, repairs typically include the following steps:

Inspection and Assessment

Use tools such as micrometers to measure the dimensions and wear of the tie bars, ensuring they meet design specifications.

Surface Treatment

For tie bars with severe surface corrosion or wear, repairs can involve grinding, polishing, or applying anti-corrosion coatings.

Replacement or Repair of Critical Components

If the tie bars are severely damaged, it may be necessary to replace them or repair critical areas such as bolt holes or connecting parts.

Machining and Adjustment of Tie Bars

- Alignment and Calibration

- Fastening and Testing

- Regular Maintenance

After repair, tie bars in die casting require precise machining and adjustment to ensure proper functionality. Specific steps include:

Alignment and Calibration

Use alignment pins and guide rails to ensure the precision of the tie bars relative to the mold.

Fastening and Testing

Tighten all bolts using a torque wrench and conduct preliminary tests under low-pressure conditions to ensure proper fit between the tie bars and the mold.

Regular Maintenance

Periodically inspect the wear condition of the tie bars and the status of fasteners, performing lubrication or replacement as needed.

Technical Improvements and Optimization

- Use of High-Performance Materials

- Automated Control

- Finite Element Analysis

To enhance the service life and performance of tie bars, we should take the following measures:

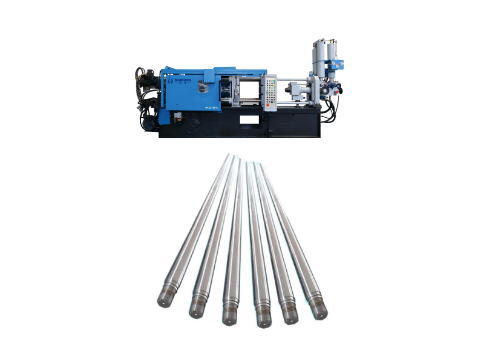

Use of High-Performance Materials

Select high-strength steel or stainless steel for tie bars to improve corrosion resistance and durability.

Automated Control

Install automatic tension adjustment devices to monitor the load on tie bars in real time and make adjustments, reducing stress fluctuations caused by thermal load changes.

Finite Element Analysis

Use finite element models to predict the stress distribution of tie bars under different working conditions, optimizing their design to improve load-bearing capacity.

Precautions and Safe Operation

- Safe Operation

- Cleaning and Protection

- Professional Guidance

When repairing and machining tie bars, we should observe the following precautions:

Safe Operation

Ensure the die-casting machine is completely shut down before performing any operations to avoid accidents caused by machine movement.

Cleaning and Protection

Keep the surface of tie bars clean during handling to prevent dust and impurities from affecting repair quality.

Professional Guidance

For complex repair tasks, consult professional technicians or refer to the maintenance manual provided by the equipment manufacturer.

The repair and machining of tie bars in die-casting machines require comprehensive consideration of their structural characteristics, operating environment, and production requirements. Through scientific repair methods and advanced technical support, the service life of tie bars can be effectively extended, and the stability of die-casting production can be improved.

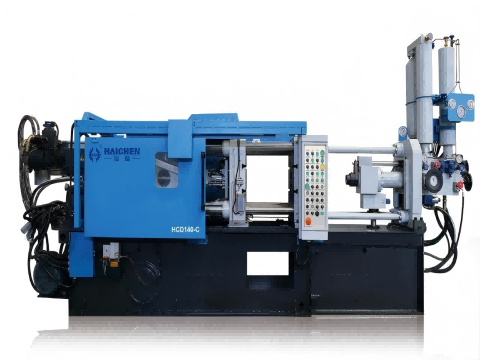

Haichen Die Cast Machine Tie Bar

Haichen is a well-known manufacturer of die-casting machines and related components. We mainly supply cold chamber, hot chamber die casting machines and auxiliary equipments. Tie bars are critical components in die-casting machines, as they provide the necessary clamping force to keep the mold closed during the high-pressure injection of molten metal. Haichen’s tie bars are designed to meet the demanding requirements of die-casting operations, ensuring durability, precision, and reliability.