Die casting machine boosting cylinders applications include improve casting quality and production efficiency, suitable for complex shapes and thin-walled parts production etc.

Booster cylinders on die-casting machines are proven enablers for better casting quality and faster production rates. They excel in forcing molten alloys into intricate geometries and filleted shells without a hitch.

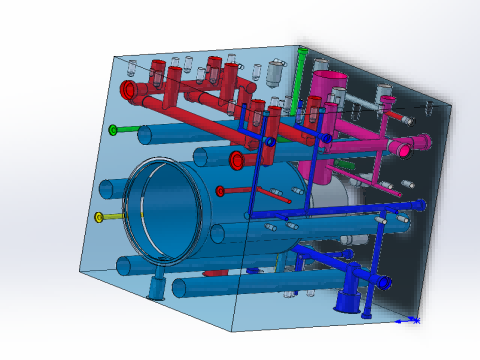

The die-casting machine’s booster cylinder is a core component that improves casting quality and production efficiency. It achieves high-pressure injection through the principle of hydraulic amplification. Its design must balance response speed, pressure accuracy, and maintainability, while also avoiding mold damage caused by overload.

The application of die casting machine booster cylinder mainly reflect in the following six aspects:

- Improve casting quality and production efficiency

- Production of complex shapes and thin-walled parts

- Reduce production costs and improve equipment utilization

- Reduced material and energy consumption

- Suitable for die casting of various metal materials

- Support automation and precision control

Improve casting quality and production efficiency

The booster cylinder is used to control the filling pressure and speed of the molten metal during the die casting process. Thereby improving the surface quality and internal structure of the casting.

For example, by designing a booster circuit, the problem of injection parameter changes caused by manual injection can be solved. Thereby improving the quality stability of die castings.

In addition, the booster cylinder can also optimize the filling process of the casting by adjusting the pressure increase time, reducing defects such as pores and shrinkage cavities.

Reduce defects of die casting machine boosting cylinders applications

- The booster cylinder increases injection pressure, ensuring a more uniform filling of the mold cavity with molten metal, minimizing defects such as porosity, cold shuts, and shrinkage.

- Precisely controlling the filling process reduces scrap and increases yield, directly reducing production costs.

Improving Mechanical Properties

- High-pressure injection increases the tensile strength of castings, making it particularly suitable for components subject to high stresses, such as sports equipment.

- The combination of high-precision molds and booster technology ensures dimensional stability and surface finish, meeting the demands of high-performance products.

Die casting machine boosting cylinders applications: Shortened Cycle Time

- The booster system optimizes injection speed and pressure, accelerating mold filling and shortening cycle time.

- Components such as high-speed core pullers can reduce cycle time by 11%, directly increasing output per unit time.

Automation and Process Optimization

- Integrated real-time monitoring sensors and data analysis tools dynamically adjust parameters to maintain efficient production.

- Reduce unnecessary downtime by optimizing the cooling system, injection parameters (such as speed/pressure), and employee training.

Reduce Material and Time Waste

- Booster technology combined with precision mold design reduces the need for subsequent processing and improves material utilization.

- Process optimization (such as reducing spraying time) can save seconds per cycle, significantly improving long-term productivity.

Production of complex shapes and thin-walled parts

The design of the booster cylinder allows precise pressure control for castings of different thicknesses.

For example, in the production of thin-walled parts such as magnesium alloy mobile phone mid-plates. The booster cylinder can achieve rapid filling and uniform solidification. Thereby improving the smoothness and dimensional accuracy of the product.

Improving Mold Filling Capacity

By providing higher pressure, the boost system enables molten metal to fill the mold cavity more evenly and quickly. This is particularly suitable for complex geometries and thin-walled structures (typically wall thickness ≤ 1mm).

This effectively reduces defects such as porosity, cold shuts, and undercasting, significantly improving product yields.

Achieving High-Precision Thin-Wall Forming

Evidence shows that boost technology can meet the production requirements of ultra-thin parts (wall thickness 0.6-1mm). Such as magnesium alloy mobile phone mid-plates.

By dynamically controlling the injection rate and pressure, the casting surface is smooth and free of flow marks, while flash and bubbles are reduced. Modern boost systems integrate real-time sensors and data analysis to dynamically optimize process parameters.

Supporting Lightweighting Demand

Thin-wall die castings significantly reduce part weight, which is crucial for lightweight design in the automotive and aerospace industries. Applications include automotive dashboards and electronic device housings.

Reduce production costs and improve equipment utilization

By optimizing the working mode of the booster cylinder, it can reduce the wear of the mold. And it can extend the service life, reduce the production costs.

In addition, the application of the booster cylinder can also shorten the production cycle time and increase the machine’s capacity.

Improve yield and reduce scrap losses

The booster cylinder increases injection pressure, allowing the molten metal to quickly fill the mold and solidify under high pressure, significantly reducing defects such as porosity and shrinkage in the casting.

Shorten production cycles and increase single-machine output

The mechanical locking design of the booster cylinder provides 250% more boost pressure, allowing the use of more compact cylinders and increasing operating speeds.

Reduced mold and auxiliary equipment costs

The intensifier cylinder’s high-pressure support capability (“no support cylinder required”) simplifies mold structure, reducing mold complexity and manufacturing costs.

Reduced material and energy consumption

Pressure boosting technology ensures efficient metal melt filling, minimizing overflow and runner residue.

Efficient Operation of the Booster System

The booster cylinder increases injection pressure and shortens filling time (the booster cylinder’s servo system response time is only 30ms). This significantly reduces cycle time (5-12%), thereby reducing energy consumption per unit product.

Reducing scrap and indirectly saving energy

By precisely controlling injection pressure, the booster cylinder improves the internal quality of castings and reduces scrap caused by defects.

Suitable for die casting of various metal materials

The booster cylinder is not only suitable for die casting of light metals such as aluminum and magnesium, but also can process low melting point alloys such as zinc and lead. This flexibility makes the booster cylinder more widely used in different industries.

Increasing Injection Pressure of die casting machine boosting cylinders applications

During the die-casting process, booster cylinders increase injection pressure to improve molten metal filling and solidification quality, reduce defects like shrinkage cavities and air holes, and enhance casting density and mechanical properties (such as tensile strength).

Challenges of High-Melting-Point Materials

Molten aluminum alloys can corrode metal cylinders and molds, shortening equipment life.

Support automation and precision control

Modern die casting machines usually equip with advanced control systems. To achieve precise control of the injection process through the booster cylinder. This includes real-time monitoring and adjustment of pressure, speed and temperature to ensure high-quality casting output.

Die casting machine boosting cylinders applications: Boost Pressure Control

The boost cylinder increases system pressure during the injection phase, ensuring that the molten metal quickly and fully fills the mold cavity. This high pressure reduces defects such as shrinkage and pores, and improves casting density and mechanical properties (such as tensile strength).

This is particularly important for high-strength applications such as automotive and aerospace components.

Thus, the application of booster cylinders in die-casting machines has greatly improved the quality of castings, production efficiency and equipment utilization. And it also provided technical support for the production of parts of different materials and complex shapes.

Achieving Precise Process Control

Millisecond-level Response: The pressurization phase requires an extremely short pressure build-up time (≤20ms) to avoid uneven filling due to solidification of the molten metal.

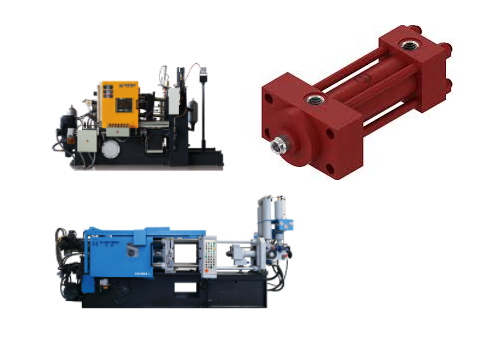

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts. When you have any demand, feel free to contact us.