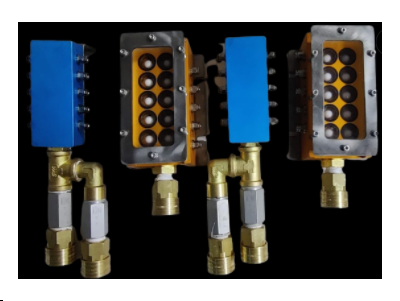

Die-Casting Machine Connector is a important application in the die casting process, mainly for the transmission of force and motion.

Depending on the design and needs, the connector can be available in a variety of materials and construction forms to meet specific functional requirements.

Haichen’s die casting machine connectors are typically made of aluminum alloys (such as ADC12, A380, etc.), zinc alloy, magnesium alloy, and other materials.

And are manufactured through the die casting process, offering high mechanical properties, corrosion resistance, and high precision.

Performance Requirements for Die-casting Machine Connectors

- High-Temperature Resistance

- Pressure Resistance

- Sealing Performance

- Materials and Coatings

High-Temperature Resistance

Die-casting machines usually operate in high-temperature and high-pressure environments, so connectors must have excellent high-temperature resistance.

For example, the temperature range of Haichen Die-casting Machine High-Temperature and High-Pressure Connectors can reach -55℃ to +200℃, and they can run stably at 200℃ for 600 hours.

In addition, accessories such as rubber joints must also have high-temperature resistance to ensure they do not deform or crack in high-temperature environments.

Besides, the die-casting machine connectors themselves have good high-temperature resistance—manufacturers mostly make them from aluminum alloys, zinc alloys, copper alloys and other materials that suit high-pressure and high-temperature industrial settings.

Pressure Resistance

Die-casting machines withstand extremely high pressure during operation, so connectors must have excellent pressure resistance capabilities.

For example, Haichen’s series of die-casting machines can reach an operating pressure of 140 MPa and run stably at 140 MPa and 200℃ for 10 hours.

In addition, high-pressure connectors must maintain stable mechanical properties under high-pressure conditions.

Such as tensile strength, flexural strength and flexural modulus, to ensure stability in complex application scenarios.

Sealing Performance

Sealing performance counts as one of the key performance indicators for die-casting machine connectors.

Accessories such as rubber joints must have excellent sealing performance to prevent hydraulic oil leakage, reduce the impact of internal air or moisture on equipment operation, and thereby improve the overall efficiency of the equipment.

In addition, high-pressure connectors must maintain reliable sealing performance under high-pressure conditions to ensure their dependability in complex application scenarios.

Materials and Coatings

The performance of die-casting machine connectors is also closely related to their materials and coatings.

For example, the reliability of crimp connectors in high-temperature environments depends on their materials and coatings.

Selecting high-temperature resistant materials such as nickel and copper alloys, and matching them with protective coatings or insulating layers, ensures their performance.

In addition, the current-carrying capacity of welded connections changes slightly in high-temperature environments.

While that of crimped connections drops sharply under high temperatures, which shows that welded connections have greater advantages in high-temperature settings.

Reliability and Stability

The reliability of die-casting machine connectors under high-pressure and high-temperature conditions depends on their design, materials and manufacturing processes.

For example, Haichen High-Pressure/High-Temperature Connectors are specifically designed for harsh environments and can deliver excellent performance and reliability under high-pressure and high-temperature conditions.

In addition, manufacturers need to optimize the manufacturing and design of die-casting machine connectors through CAD/CAE and finite element analysis technologies to ensure their performance and reliability.

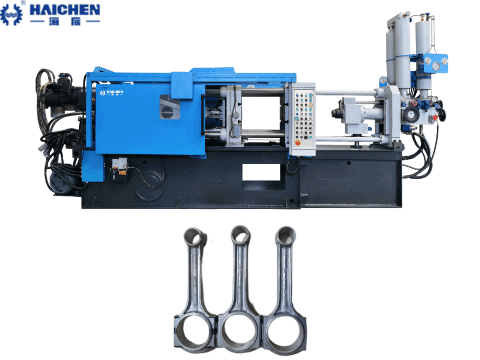

Parts or Components of Die Casting Machines and Their Uses

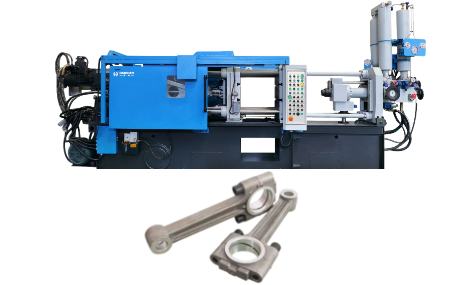

HAICHEN die casting machines are complex machines used to manufacture metal parts with high accuracy and consistency.

Some of the main parts of a die casting machine include:

- Die/Mold

- Injection System

- Clamping Unit

- Hydraulic System

- Ejector System

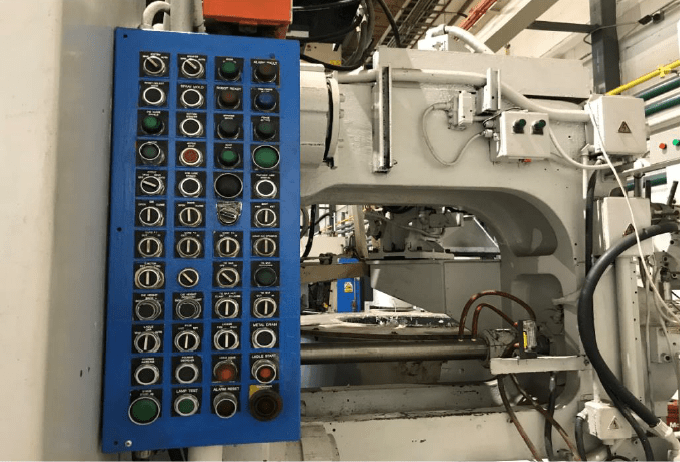

- Control System

- Cooling System

- Lubrication System

- Safety System

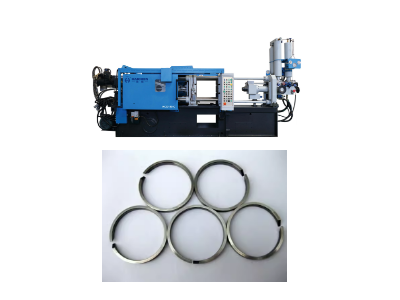

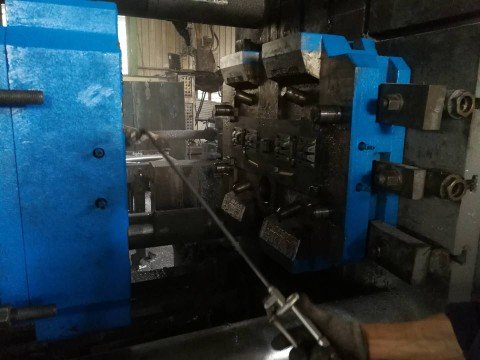

Die/Mold

The die is the tool used to shape the metal into the desired form. It consists of two parts, the fixed die half and the movable die half.

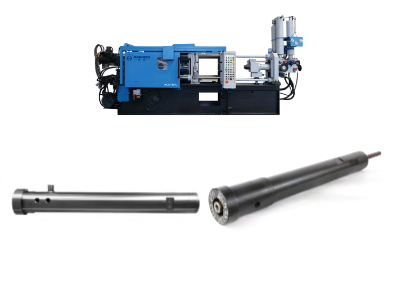

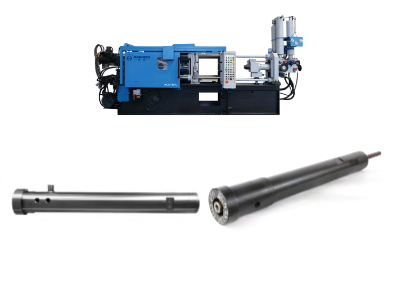

Injection System

The injection system includes the shot sleeve, plunger, and gooseneck. The molten metal is injected into the die cavity through the injection system.

Clamping Unit

The clamping unit is responsible for holding the die in place during the casting process. It consists of the stationary platen, movable platen, tie bars, and toggle mechanism.

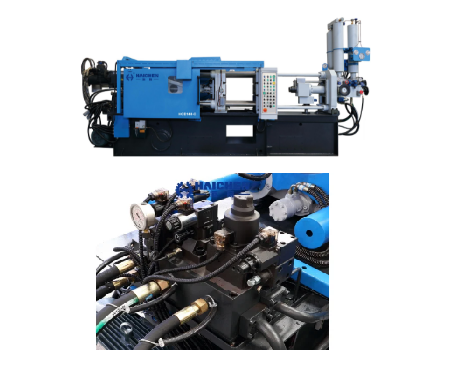

Hydraulic System

The hydraulic system provides the power to move the various components of the machine, such as the injection system, clamping unit, and ejector system.

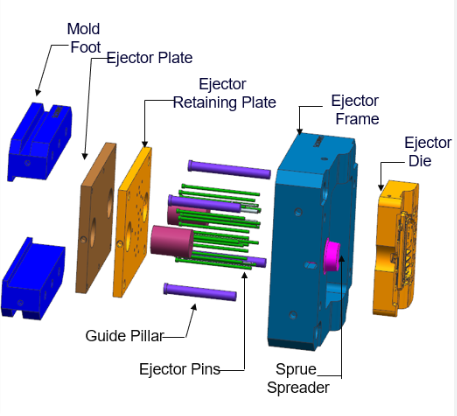

Ejector System

The ejector system is responsible for ejecting the casting from the die cavity once the casting has solidified. It includes ejector pins, an ejector plate, and an ejector cylinder.

Control System

The control system manages the operation of the die casting machine. It includes the machine controller, sensors, and actuators.

Cooling System

The cooling system helps to control the temperature of the die and the casting during the casting process. It includes cooling channels in the die and a water cooling system for the machine.

Lubrication System

The lubrication system is responsible for lubricating the various moving parts of the die casting machine to reduce friction and prevent wear and tear.

Safety System

The safety system includes various safety features to protect the operator and the machine from accidents. It includes safety guards, emergency stop buttons, and safety interlocks.

Material selection

Connecting rods often need to be high strength and abrasion resistant to withstand the high loads and wear of the die casting process.

For example, the connecting rod material of the mechanical structure uses carbon steel (such as S45C) or more to avoid wear or deformation due to insufficient strength.

In addition, die-cast zinc-based or aluminum-based alloys are suitable for different application scenarios.

Structural design

The design of the connecting rod needs to consider its specific role in the die-casting machine.

For example, in the floating piston connection structure of the die-casting machine.

The connecting rod and pressurized piston rod are a single unit.

The O-ring on the connector is eliminated to improve the stability of the oil pressure.

In addition, auxiliary support rods and V-shaped support frames, enhance their strength and prevent deformation.

Functional Applications

Compared to traditional steel linkages, Haichen‘s aluminum connecting rods are lighter and are especially suitable for areas where weight is high, such as racing cars and motorcycles.

Aluminum itself has good thermal conductivity, which helps to dissipate heat better in high-temperature engine systems.

Additionally, aluminum is more suitable for CNC machining and can be designed into connecting rods with various complex structures to suit different application needs.

Innovative design

With the development of technology, the design of connecting rods is also constantly innovating.

For example, in a die-casting device for low-pressure casting casings.

The connecting rod achieves high-frequency intermittent traction through a servo-motor traction system.

And the pitch is adjusted according to the diameter of the casting rod to ensure stable operation.

The latest material technology of Die-Casting Machine Connector

- Aluminum alloy extrusion casting

- Magnesium alloy die casting

- High thermal conductivity aluminum-magnesium alloy material

- High Toughness Die-Cast Aluminum Alloy

- High-strength wear-resistant die-casting aluminum alloys

- Carbon Fiber Reinforced Plastics (CFRP)

Aluminum alloy extrusion casting

At present, the aluminum alloy connecting rod of the air compressor mainly uses ZL108, ZL202 and other materials, and the extrusion casting process is applied.

This process crystallizes and solidifies the liquid aluminum alloy material under pressure.

And can obtain high-quality connecting rods with dense and uniform structure, fine grains, good mechanical properties, smooth surface and low machining amount.

Which meets the requirements of lightweight design and is conducive to the improvement of air compressor performance.

Magnesium alloy die casting

Magnesium alloy is widely used in automotive parts due to its lightweight properties.

Marking the project has entered the mass production stage.

In addition, Baowu Magnesium signed a strategic cooperation agreement with LG Electronics to jointly develop a strategic letter of intent for magnesium alloys.

High thermal conductivity aluminum-magnesium alloy material

Haili New Materials has a complete production process system in the production of magnesium alloy and aluminum alloy precision die castings.

They overcame the problems of high viscosity and easy adhesion of superconducting materials.

And significantly improved the yield and stability of die casting.

This material helps to improve the thermal conductivity of die castings and meet the needs of diverse 5G base station aluminum-magnesium alloy die casting products.

High Toughness Die-Cast Aluminum Alloy

SUMIKALLOY T-31D is a high-toughness die-cast aluminum alloy with excellent casting performance, better than ADC12 alloy.

Suitable for engine connecting rods, agricultural machinery engine connecting rods and bicycle components.

High-strength wear-resistant die-casting aluminum alloys

ST-K, ST-J, ST-H and other high-strength wear-resistant die-casting aluminum alloys have excellent wear resistance.

Which can be selected according to the requirements of strength, corrosion resistance and thermal conductivity.

And are suitable for automatic transmission valve bodies, automobile compressor sliding parts and wear-resistant transmission forks.

Carbon Fiber Reinforced Plastics (CFRP)

Although carbon fiber reinforced plastics (CFRP) have not yet achieved satisfactory fatigue strength and are costly.

At this point,their lightweight and high-strength properties make them have great potential for future applications.

Your Trusted Aluminum Connecting Rods Manufacturer in China

During the operation of the engine, aluminum connecting rods are under tremendous pressure to drive the engine.

The lighter weight of aluminum not only reduces the vibration of the engine but also reduces the engine acceleration time, which improves the vehicle’s starting efficiency.

Haichen has a wide range of aluminum connecting rod types to meet your needs in different industries.

Whether you need structural aluminum connecting rods or high-precision CNC machined aluminum connecting rods and high-strength forged aluminum connecting rods.

We have rich manufacturing experience and a professional design team to provide you with the best aluminum connecting rod solutions.

Haichen Die-Casting Machine Connector maintenance

- Regular inspection and tightening

- Hydraulic system maintenance

- Maintenance of the lubrication system

- Maintenance of the cooling system

- Maintenance of the electrical system

- Operation specifications

Regular inspection and tightening

Check the looseness of the connecting fasteners every week to ensure that all the connecting parts are fastened in place to avoid equipment failure caused by loosening.

Check the position of the nut of the bar every month to ensure that it is in the correct position and prevent the connecting rod from falling off due to loose nuts.

Hydraulic system maintenance

Check the hydraulic oil level and pipeline leakage to ensure the normal operation of the hydraulic system.

Change the hydraulic oil regularly, every 500 hours and every 2000 hours thereafter to maintain the cleanliness and viscosity of the hydraulic oil.

Check the filter element in the hydraulic system and clean or replace it regularly to ensure the cleanliness of the hydraulic oil.

Maintenance of the lubrication system

Regularly lubricate the non-automatic lubricated sliding friction surface to ensure that the sliding part of the connecting rod is fully lubricated.

Check the working condition of the automatic lubrication system to ensure its normal operation.

Maintenance of the cooling system

Regularly inspect the cooling system to ensure that the cooling effect is good and prevent the equipment from overheating.

Check the cooling water channels to ensure that the water flows smoothly and avoid equipment failures caused by poor cooling.

Maintenance of the electrical system

Regularly inspect the electrical control box to keep the interior dry and tidy to prevent foreign objects from entering.

So,check the working status of electrical wiring connections and electrical components to ensure the safety and reliability of the electrical system.

Operation specifications

In brief,operators need to be trained to understand the use of equipment.

Maintenance knowledge and safe operation specifications to ensure the normal operation of equipment and personnel safety.

Comply with safety operating procedures such as checking the range of motion of the machine before start-up.

Checking connection fasteners and pressure changes before using high-pressure nitrogen, etc.