The die casting machine ejector stroke is the maximum movement distance of the ejector of the die casting machine.

It is an important parameter to measure the demoulding ability of the die-casting machine. The die casting machine ejector stroke is represented by S and the unit is mm.

The importance of ejection stroke

The Die casting machine Ejector stroke refers to the maximum distance that the ejector pin or push rod can move when the ejector mechanism pushes the casting out of the mold during the die casting process. This parameter is very important to ensure that the casting can be demolded smoothly and avoid damage.

1. Ensure the integrity of the casting

The appropriate ejector stroke can ensure that the casting does not break or damage when it is removed from the mold, especially for castings with complex structures or thin walls.

2. Improve production efficiency

The correct ejector stroke helps to speed up demolding and reduce production cycle time, thereby improving overall production efficiency.

3. Reduce material waste

If the ejector stroke is not set properly, it may cause damage to the casting, increase scrap rate and material waste.

Factors affecting Die casting machine Ejector stroke

The ejector stroke setting needs to be adjusted according to the size, shape, and material properties of the casting to ensure that the casting is not damaged during the ejection process. By optimizing these factors, the ejector stroke of the die casting machine can be effectively improved, thereby improving production efficiency and product quality.

1. Casting design

The size, shape, and structural complexity of the casting directly affect the required ejector stroke. Complex geometric shapes or deep cavity structures may require longer ejector strokes.

2. Mold design

The ejector pin position, number and layout of the mold will affect the ejector stroke. Reasonable mold design can ensure that the casting is demolded evenly and smoothly.

3. Ejector force

The ejector force is the maximum thrust generated by the ejector mechanism of the die casting machine, which determines the maximum distance that the ejector mechanism can eject the die casting. The size of the ejector force directly affects the length of the ejector stroke.

4. Ejector size and number

The size and number of ejectors must match the ejection requirements of the casting. Insufficient ejector number or improper size may lead to uneven distribution of ejector force.

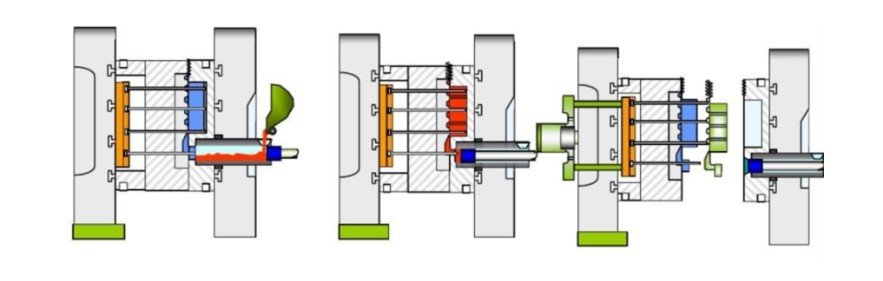

Ejector stroke measurement for die casting machine

The measurement of the ejector stroke of die casting machines is a key step to ensure smooth de-moulding of castings. It involves using high-precision measuring tools to determine the total distance the ejector moves from the fully retracted position to the time when the casting is ejected. This process requires the mold and ejector to be in good condition under safe conditions, taking into account the impact of environmental factors on the measurement results, ensuring that the operator has the appropriate skills, and recording all data for subsequent analysis and quality control.

Haichen die casting machine

In die-casting production, ejector stroke is a crucial parameter, which is directly related to the demolding efficiency and quality of castings. Correctly measuring and optimizing the ejector stroke can not only improve production efficiency, but also reduce material waste and improve the yield rate of castings.

As the die-casting industry continues to develop towards automation and intelligence, it is particularly important to choose a die-casting machine with high precision and high reliability. Haichen die-casting machine, with its advanced technology and excellent performance, provides users with the ability to accurately control the ejector stroke, ensuring efficient and stable demolding in the production of various complex castings.

When you choose a suit die casting machine, the die casting machine Ejector stroke must be considered clearly. Because we have to ensure that the products can be ejected down from the mold.