Die casting machine extractor in China has shown a significant growth trend.

Die casting machine extractor in China market demand continues to grow and the scale of the industry continues to expand. In particular, the expansion of downstream application areas such as automobiles, motorcycles, and home appliances has brought new growth points to the die-casting industry.

China’s die-casting machine extraction machine industry has made significant progress in the fields of automation integration and large-scale equipment supporting. However, high-end precision extraction technology still relies on imports, and in the future it is necessary to break through the technical bottleneck of core components (such as high-speed grippers and intelligent sensors) and expand large-scale applications based on the new energy vehicle market.

The core development trend of China’s die-casting machine pickers is automation. Efficiency is improved through four-station manipulators, ejector collaborative design and high-precision monitoring. The technical difficulty lies in the demoulding and residue control of complex castings, while modular customization and energy efficiency optimization are the main development directions. At present, the demand for automation upgrades in small and medium-sized enterprises is significant, and the degree of mechanization in the picking process directly affects production efficiency. It mainly includes following four factors:

Die casting machine extractor in China technological progress and policy support

In recent years, China’s die-casting industry has made significant technological progress, especially in the field of aluminum alloy precision die-casting.

In addition, the government has introduced a series of policies to promote the innovation and upgrading of die-casting technology, such as the “Implementation Plan for Carbon Peaking in the Industrial Field”, which will help promote the green, efficient and intelligent transformation of the die-casting machine industry.

Technology R&D-oriented policy support

Fiscal policy gives priority to supporting the technological upgrading of small and medium-sized enterprises, emphasizing environmental protection investment and regional balanced development. For example, tax incentives or subsidies are provided for the digital transformation of die-casting equipment to promote the implementation of CAD/CAE/CAM technology.

Research has confirmed that policy support can significantly enhance the synergy between manufacturing technology and corporate strategy (such as quality, delivery and other indicators), but has limited effect on cost control.

Industrial upgrading and structural adjustment policy

The state promotes technological progress in the manufacturing industry through legislation and special plans. The die-casting industry can obtain R&D funds and test platform support by analogy. Chinese companies can improve their technology level faster through the “introduction-digestion-joint R&D” model, and policies should focus on encouraging such paths.

Die casting machine extractor in China expand of market scale

According to the statistics and estimates of Toubao Research Institute, from 2017 to 2022, the market scale of our country’s die-casting machines will grow from 6 billion yuan to 19.2 billion yuan, with an annual compound growth rate of 26.19%.

It is expected that by 2023 and 2025, die casting machine auto extractor in China market scale will exceed 20 billion yuan and 30 billion yuan respectively.

Promotion of the new energy vehicle industry

The rapid development of new energy vehicles (NEV) is one of the main driving forces for the growth of the die casting machine market. According to the forecast of the China Association of Automobile Manufacturers, China’s new energy vehicle sales will exceed 5 million in 2022, becoming the world’s largest new energy vehicle market.In order to meet the demand for lightweight and integrated components of new energy vehicles, die casting technology has been widely used.

Market demand for large die-casting machines

As new energy vehicles increase their demand for lightweight and integrated components, the market demand for large die-casting machines is also growing rapidly. According to relevant research, the global large die-casting machine market is expected to grow explosively between 2021 and 2026, especially driven by the Chinese market.

Die casting machine extractor in China improve international competitiveness

Domestic die-castings have begun to go abroad to participate in international market competition, and some companies will also import advanced die-casting equipment, die casting machine extractor and raw materials from abroad.

Chinese die-castings and Chinese extractors have certain competitiveness in the international market, especially in the field of mid- and low-end products.

Global layout and market expansion

Chinese die-casting machine companies are actively expanding the international market through global layout. Yizumi has established multiple production bases and service centers around the world, including India, Germany, the United States, Mexico, Vietnam, Thailand, Turkey and other countries and regions

This global strategy not only helps companies better adapt to customer needs in different markets, but also enhances its influence in the global market.

Improvement of industrial chain and development of industrial clusters

China has formed a relatively complete industrial system in die-casting machines and related industrial chains. For example, Ningbo, as an important base of China’s die-casting machine industry, has formed a full range of industrial chains from die-casting machines, molds, materials to CNC processing.

The advantages of this industrial cluster not only reduce the production costs of enterprises, but also improve the overall competitiveness of products. In addition, Ningbo’s industrial cluster also provides customers with a complete solution from mold design, die-casting machine manufacturing to subsequent processing through a “one-stop” service model.

Expansion of die casting application areas

With the transformation and upgrading of the manufacturing industry and the rapid development of intelligent manufacturing, the die-casting industry will usher in more development opportunities.

The rise of emerging industries such as new energy vehicles and smart home appliances will bring new market demands to the die-casting industry. And the application of technologies such as digitalization, networking, and intelligence will also promote the die-casting industry to a higher level of development.

Automation and Intelligence

The extractors of modern die-casting machines are usually equipped with automatic control systems, which can automatically extract castings from the mold and detect whether the castings are complete through sensors. For example, the extractor head assembly H is driven by a hydraulic system to achieve linear motion and is equipped with sensors to ensure that the castings are completely extracted.

Industry application expansion

Extractors of die casting machines have been widely used in multiple industries. Die casting is mainly used for large-scale production, such as wheels, cylinder blocks, cylinder heads and other parts in the automotive industry. Die casting is not only widely used in the automotive industry, but also plays a role in consumer electronics, aerospace, home appliances and industrial equipment. For example, it is mentioned that die casting is used in the aerospace field to manufacture high-strength and precision parts.

Die casting machine extractor manufacturer in China

The following are several Chinese die casting machine automatic extractor equipment manufacturers:

- FOSHAN ZHENYANG AUTOMATION SCIENCE AND TECHNOLOGY CO., LTD.

- Address: No. 5, Yanbuhuan Town Industrial Zone, Dali Town, Nanhai District, Foshan City, Guangdong Province

- Jiangmen Zhenli Machinery Co., Ltd. Address: Jiangsha Industrial Zone, Jiangmen City, Guangdong Province

- Wuxi Muler Machinery Technology Co., Ltd. Address: Wuxi, jiangsu province

- ZHENLI Machinery Co., Ltd.

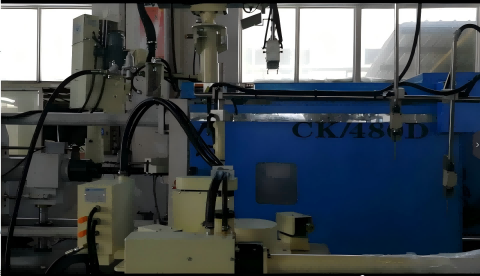

Haichen die casting machine extractor

Haichen is one Chinese die casting machine manufacturer. It produces high pressure die casting machines.

It includes cold chamber die casting machines and hot chamber die casting machines.They have durable and highly precise features.We also produce product good quality Chinese die casting extractor to improve the die casting manufacture and production efficiency.

Extractor in China is in a stage of rapid development. The market scale continues to expand, and the application areas continue to expand.

With the continuous changes in domestic and foreign markets and the intensification of competition, die-casting companies need to continuously improve their own strength to adapt to market changes and challenges.