Die Casting Machine Hydraulic Valves Brand TOP5:

- Rexroth

- Parker

- HAWE

- Bucher

- Hengli

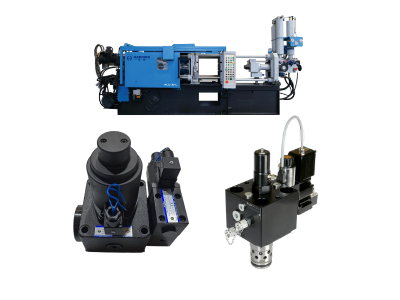

Hydraulic valves are used in die casting machines to precisely control the flow direction, pressure.

And flow of hydraulic oil, enabling critical actions such as molten metal injection, mold opening and closing, and temperature regulation.

Rexroth

Rexroth has long occupied the top market share of hydraulic valves (about 18%).

And is known for its high-precision electromagnetic directional valves, speed control valves and other products in the field of die-casting machines.

Performance Parameters

Maximum operating pressure: 350 bar Flow range: 80 L/min (e.g. 4WE6E62/EG24N9K4 solenoid directional valves).

Response time: servo valve up to 1.5ms (e.g. 4WS.2E type).

Application scenarios: Widely used in CNC machine tools, die-casting machinery, steel plant hydraulic systems.

Its products are adopted by high-end equipment around the world with modular design and high reliability.

Parker

A leader in high-end proportional valves.

Parker’s PV Series and D1VW Series proportional valves are known for their precise flow control.

And support for highly dynamic pressure regulation in die casting machines.

Performance Parameters

Nominal pressure: 350 bar (e.g. PV063R1K1T1NFF1 electro-hydraulic proportional valves)

Flow range: up to 1600 L/min (4WRZ(E) proportional valves)

Industry reputation: Its products are recognized for their high compatibility and low energy consumption design in the field of industrial automation, especially in North America and Asia.

HAWE

Experts in the field of high pressure

The proportional valves of the PSL series from HAWE with a maximum working pressure of 420 bar are suitable for heavy-duty hydraulic systems in die-casting machines.

Technical Highlights: All-steel structure valve body, high pressure resistance and small size (e.g. PSL5H2/160-3 valve).

Flow range: 3-210 L/min, support multi-scenario modular configuration.

Market performance: Global sales exceeded 500 million euros, and die-casting machine customers covered steel mills, mining equipment and other heavy machinery fields.

Bucher

CINDY series balancing valves (e.g. CINDY16-B-PND-S150-A-G6-7) are designed for die casting machines and support high pressures (420 bar) and precise load control.

Technical Parameters

Maximum flow rate: 50 L/min Pressure capacity: 420 bar (e.g. BBV6 series).

Market layout: Swiss original products are sold directly in the Chinese market through the Suzhou subsidiary.

With outstanding stock supply capacity, and customers include aerospace and heavy equipment manufacturers.

Hengli

Breaking the monopoly of foreign capital, the domestic share of excavator pumps and valves reached 35%, and the domestic substitution space in the non-digging field is broad.

Product performance

Rated pressure: 420 bar (e.g. HVP0-M24 safety valve).

Response time: high-frequency response valve ≤ 1.5ms, more than 3 million times of switching.

Globalization strategy: through the acquisition of German Inle, the layout of the Mexican factory, expand the die-casting machine and other overseas high-end markets.

Other hydraulic Valves competing brands

Kawasaki

A joint venture with Eddie Precision to develop high-end pump valves.

But its market share in the die-casting machine field is slightly lower than that of the TOP5.

MOOG

Servo valve technology is leading (e.g., D661-4718).

But it is mainly concentrated in ultra-precision fields such as aerospace, and there are few applications for die casting machines.

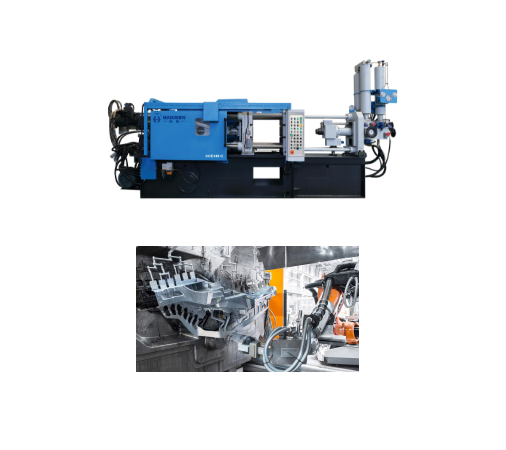

Chinese hydraulic Valves brand

The brand selection of hydraulic valves for die-casting machines needs to consider the pressure range, flow accuracy, response speed and cost.

International brands (e.g. Rexroth, Parker) dominate the high-end market.

While Chinese brands ,such as Haichen Machinery is gradually increasing their competitiveness.

Future trends include intelligence (IoT integration) and energy-efficient design.

And the demand for proportional and servo valves will continue to grow.