Die casting machine platens selection guide includes platen type, select guide devices and material, clean and maintenance, etc.

The die casting machine platens are the cornerstone for ensuring high-pressure injection accuracy. Two-template models have become a trend due to their high efficiency and compactness, but they rely on high-rigidity materials and advanced hydraulic control technology.

When choosing a die casting machine platens, we suggest you to consider about five main factors as below:

- Platen Type

- Selection of guides devices

- Material selection

- Selection of mold steel

- Other accessories

Platen Type

Die casting machine platen type selection depends on the die casting machine design and requirements, platens are usually classified as fixed platens, movable platens, and adjustable platens. Fixed platens are located at the “shot” end of the machine. Movable platens are located between the fixed platens and adjustable platens. And adjustable platens are located at the rear of the machine and are used to adjust the die height.

Stationary Platen

Located at the “injection end” of the die-casting machine, it secures the cover die of the mold and aligns it with the injection system (e.g., the shot sleeve).

It must withstand extreme pressure (often exceeding 1,000 tons) and is constructed of thick steel to prevent deformation.

Its surface is designed with T-slots or threaded holes for mold clamping. Regular cleaning is required to ensure parallelism between the mold parting surface and the platen and to ensure efficient heat transfer.

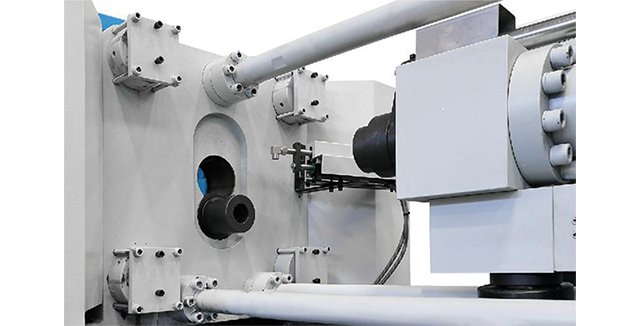

Moving Platen

Located between the stationary platen and the rear platen, it secures the ejector die of the mold.

It uses a hydraulic/mechanical system to actuate the mold opening and closing, enabling mold closure and casting ejection.

It also requires a high-rigidity design, and its surface cleaning and maintenance requirements are the same as those for the stationary platen.

Adjustable Platen

Equipped on some machine models, it slides along tie rods to adjust mold height or accommodate molds of varying sizes.

This is particularly critical in ultra-large die-casting machines (e.g. single die plate size up to 4m×4m/60 tons) to compensate for the assembly tolerance of giant molds.

Selection of guides devices

Guide devices (such as guide pins and bushings) are key components. They ensure precise alignment of the mold halves during opening and closing. Choosing the right type of guide device (e.g., sleeve guides, pin guides) depends on the type of mold base and the required accuracy.

Shoulder/Straight Guide Pins & Bushings

Standard configuration, used for general precision molds.

Self-lubricating Bushings

Reduce wear, suitable for high-volume production.

Bronze-Plated Bushings

Enhanced wear resistance, suitable for high-load conditions.

Large Guide Pins (2″–3″ diameter)

Used for large molds, made of hardened alloy steel to ensure rigidity.

Key Selection Factors

- Mold Size and Weight: Large molds require large-diameter guide pins (e.g., 3″) to withstand the load.

- Production Volume: High-volume production requires highly wear-resistant materials (e.g., bronze-plated or self-lubricating bushings).

- Precision Requirements: High-precision products (e.g., thin-walled parts) require enhanced guide design, and custom guide pins may be required.

- Formwork Material: Formwork is commonly made of ductile iron, and the machining accuracy of the guides and the formwork mounting surface must be matched.

Material selection

The template material needs to have sufficient strength and durability while being able to withstand the high temperatures and pressures of the die casting process. Commonly used materials include high-strength steel and other heat-resistant materials.

Core Structural Components (Formwork Body)

High-strength steel

As the preferred material for formwork, it must withstand extreme pressures exceeding 1,000 tons and resist deformation. Ductile iron is also widely used due to its excellent mechanical properties (strength and toughness) and processability.

Key Performance Requirements

- Compressive Strength: Ensures structural stability under high pressure to prevent micro-deformation that affects casting accuracy.

- Wear Resistance: To withstand the long-term impact of mold opening and closing, the material must possess high surface hardness.

Frame and Support Structures

- High-strength steel or cast iron: Used for the equipment frame, ensuring overall rigidity and thermal stability to maintain long-term operational accuracy.

- Surface Treatment: Electroplating or heat treatment (such as nitriding) can be used to enhance.

- corrosion resistance and fatigue strength, ensuring suitability for various industrial environments.

Special Working Conditions

- High-Temperature Alloys: If the formwork will come into contact with high-temperature molten metals (such as aluminum or magnesium alloys), core components must be made of stainless steel or heat-resistant alloys (such as H13 tool steel) to resist thermal fatigue and corrosion.

- Corrosion Resistance Requirements: In chemical or humid environments, stainless steel (such as STS series) is preferred. Its chromium content forms a passive film that resists chemical attack.

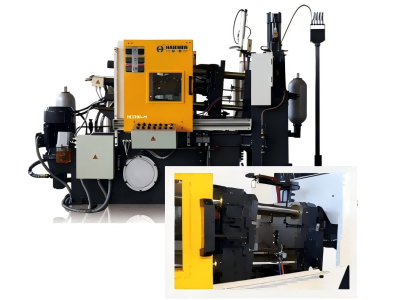

HAICHEN die casting machine platens selection guide

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features. It builds platens to match the machines’ performance and clients’ requirement.

- Robust Design for Heavy-Duty Cycles

- Customizable Options for Special Molds

- Integrated System Compatibility

Robust Design for Heavy-Duty Cycles

HAICHEN platens use high-grade cast steel. They are thick and have strong ribbing. This is crucial for machines running high-pressure aluminum casting all day. Our platens stay flat and true, cycle after cycle.

Customizable Options for Special Molds

Some molds are very large or have unique mounting needs. HAICHEN can provide platens with special hole patterns or extra thickness. We work with clients to make sure the platen fits their specific mold.

Integrated System Compatibility

A HAICHEN platen is made for a HAICHEN machine. The dimensions and hole patterns are precise. This guarantees perfect fit and force distribution. It also makes service and parts replacement simpler.

A Critical Choice for Your Operation

Selecting the right platen is a critical part of your die casting machine platen selection guide. It directly impacts part quality, setup speed, and machine life. Do not choose a platen that is just “big enough.” Choose one that is strong, precise, and perfectly matched to your mold and machine. HAICHEN provides this engineered compatibility, offering platens that are built to last and perform reliably in demanding production environments.

Selection of mold steel

The choice of mold steel directly affects the durability and corrosion resistance of the mold. The appropriate mold steel should be selected according to the specific application requirements. Such as considering its dimensional stability, corrosion resistance, casting convenience and cost.

High-Temperature and High-Pressure Resistance

Die-casting molds must withstand extreme conditions (temperatures > 600°C and pressures > 1000 tons), requiring steel with high thermal fatigue resistance, wear resistance, and toughness.

Recommended hot-work die steels include H13, SKD61, 8407, and 2344, as these materials maintain strength and resistance to melting loss even at high temperatures.

Matching Production Requirements

- Batch Size: High-wear-resistant steel (such as H13) is required for large-scale production (>100,000 pieces). For small and medium-sized batches, the more cost-effective P20 steel (suitable only for low-melting-point alloys such as zinc alloy) can be considered.

- Product Precision: High-precision parts require steel with minimal heat-treatment deformation (such as D2 steel).

- Mold Size: Large molds should be made from a steel grade with excellent machinability and long life (such as pre-hardened 718 steel).

Other accessories

In addition to the template, you also need to choose suitable accessories. Such as hydraulic core pulling mechanism, suitable mold holder, vacuum die casting system, etc.

Guide and Positioning Devices

- Guide Pins/Guide Bushings: Ensure mold opening and closing accuracy. Selection should be based on the mold base type (e.g., sleeve-type, pin-type). The material must be wear-resistant. When selecting, consider mold life and machining accuracy requirements.

- Locate Pins: Used for precise mold positioning. The design should consider thermal expansion coefficient and compressive strength.

Hydraulic System Components

- Hydraulic Cylinders: Drive the moving platen. They must meet clamping force requirements (typically >1000 tons) and response speed. Three types are listed: shot cylinders, ejector cylinders, and clamping cylinders.

- Piston Rods: Require high-strength alloy steel (e.g., 40Cr) with a hardened surface for wear resistance.

- Accumulators and Nitrogen Cylinders: Provide instantaneous high pressure to shorten cycle times. Pressure stability and safety valve configuration should be considered when selecting.

Connection and Transmission Components

- Shooting Head/Connector: Preferred materials are 45# steel or 40Cr. After rough machining, they are fully quenched and tempered, and finished with a black finish. Key Point: Ensure coaxiality with the shot rod; otherwise, breakage is likely.

- Toggle System: Contains pins and bushings, requires regular lubrication, and attention should be paid to fatigue resistance when selecting.

Taking all the above factors into consideration, choosing a suitable die-casting machine template requires a comprehensive evaluation based on specific production needs, equipment performance, and mold design requirements.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.