Die casting plunger rod maintenance includes lubricationg and cooling, regular inspection and seals replacement and others.

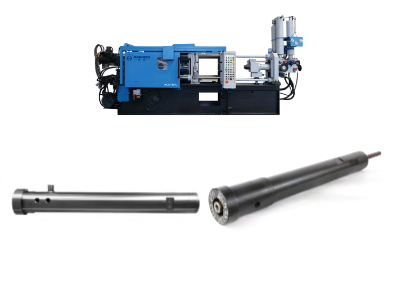

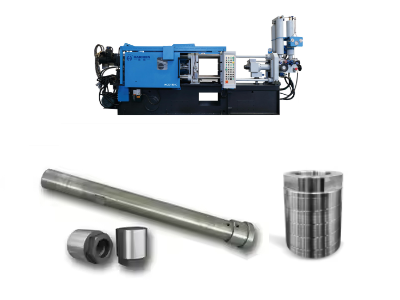

The plunger rod of a die casting machine is a key component in the die casting system. Its main function is to transmit the pressure of the hydraulic system to the plunger barrel, thereby injecting the molten metal into the mold.

- Lubrication and cooling

- Regular inspection and replacement of seals

- Avoid excessive wear

- Use high-quality materials

- Preventive maintenance program

- Optimized design

Lubrication and cooling

The plunger rod requires a good lubrication and cooling system to extend its service life and prevent wear.

For example, the use of a cooling line design can keep the plunger rod at a suitable temperature in the high-temperature area, thereby improving functionality and life.

At the same time, lubrication between the plunger rod and the plunger head is also crucial, which helps reduce friction and thermal fatigue.

Before starting the machine (daily)

- Check the lubricating oil tank level and top up to the specified range.

- Check the cooling water tank water level, temperature, and pressure gauge.

- Visually inspect the cooling lines for leaks or scaling.

Each production cycle of die casting plunger rod maintenance

- Before the plunger enters the barrel, the automatic oil/particle system applies oil (approximately 0.5 ml/spray) to the plunger tip and the inner wall of the barrel.

- Start the water cooling system, ensuring a water flow rate of ≥5 GPM (corresponding to the plunger size) and maintaining an inlet temperature of 40-45°C.

At the end of each shift

- Clean any residual lubricant from the plunger surface to prevent contamination from entering the next cycle.

- Inspect the cooling water circuit for abnormal noise or vibration.

Regular inspection and replacement of seals

During maintenance, plunger rod seals (such as O-rings), it should inspect and replace to ensure their normal operation and prevent leakage.

die casting plunger rod maintenance: Inspection Frequency

- Daily Inspection: Visually inspect the seal for leaks, oil seepage, or unusual noise after each shift or every 500-1000 strokes.

- Periodic Inspection: Perform a complete seal disassembly inspection every 3-6 months (or after 10,000-15,000 cumulative strokes).

Inspection Details of die casting plunger rod maintenance

- Seal Appearance: Observe for signs of wear, tearing, scratching, or chemical degradation. If the seal’s outer diameter is flattened or cracks appear on the surface, replace it immediately.

- Seal Seat: After cleaning, inspect the metal seat surface for scratches or residual oil to prevent damage to the new seal during reassembly.

- Punch Rod: Inspect the rod for bends, scratches, or significant wear. If scratches or dents are found, replace or reprocess it before assembly.

- Lubrication: Verify that the seal is lubricated with an appropriate process-compatible lubricant (e.g., petroleum-based grease should not be used on EPDM seals) to prevent swelling or hardening.

Avoid excessive wear

It should design the plunger rod to ensure that the gap between it and the plunger head is minimized. That to prevent material penetration and excessive wear.

In addition, thermal expansion of the plunger rod may cause dimensional changes. So it requrie regular calibration to maintain accuracy.

Regular Inspection and Measurement

Perform a visual inspection of the punch rod surface, bearings, and seals at the intervals specified in the equipment manual (e.g., every 500 hours or monthly).

Measure the rod diameter, threads, and end faces for scratches, dents, or excessive wear.

If wear exceeds the allowable value, replace it promptly to prevent further wear and tear, leading to seizure or leakage.

Maintain adequate and proper lubrication

- Use a dedicated punch lubricant (containing rust and anti-wear additives) and evenly apply it to the punch rod, piston sleeve, and seal ring before and after the stroke.

- Regularly check the cleanliness and viscosity of the hydraulic oil, replenishing or replacing it as necessary to ensure sufficient oil film thickness and reduce metal-to-metal friction.

- Avoid over-lubrication to prevent oil from attracting particles and causing secondary wear.

Haichen comprehensive after-sales support

Haichen provides end-to-end support to maximize the life and performance of your plunger rod and entire machine.

- Solve Chronic Rod Wear with Engineering Support

- Service Package: Genuine Parts, Remote Diagnostics, and On-Site Service

- Training and Documentation for Proactive Maintenance

Solve Chronic Rod Wear with Engineering Support Case

A manufacturer reported excessive plunger rod wear every 3 months on their 800-ton machine. HAICHEN engineers conducted a remote analysis of their process data and lubrication logs. They identified that the alloy’s high operating temperature exceeded the standard lubricant’s rating. HAICHEN recommended a switch to a specialized high-temperature lubricant and supplied a rod with an upgraded surface coating. This extended the service interval to over 12 months, reducing downtime and parts cost.

Service Package Genuine Parts, Remote Diagnostics, and On-Site Service

We ensure long-term reliability by offering OEM-quality replacement rods engineered for perfect fit. Our support includes remote diagnostics to troubleshoot issues and dispatch expert technicians for complex repairs, minimizing your production stoppage.

Training and Documentation for Proactive Maintenance

Haichen provides detailed maintenance manuals and operational training. This empowers your team to perform correct daily checks and lubrication, preventing problems before they occur and ensuring optimal machine health.

Control stroke speed and pressure

- When using segmented control (slow fill, high-speed injection, hold pressure), maintain smooth stroke acceleration to avoid sudden acceleration that can cause impact wear on the punch rod.

- Set reasonable injection pressure and flow rate to prevent axial impact and thermal shock of the punch rod caused by excessive pressure.

The connection rod is a critical force-transmission component within Haichen’s toggle clamping system. It precisely converts the hydraulic cylinder’s thrust into the immense, amplified clamp force required to securely lock the die. Haichen’s connection rods are built for exceptional durability and fatigue resistance under extreme cyclic loads. This ensures long-term structural integrity, minimizes deflection for consistent part quality, and is fundamental to the machine’s renowned reliability and stable, high-performance operation over millions of cycles.

Use high-quality materials

Selecting the right materials (such as copper alloy, ceramic or copper-titanium alloy) is essential to improve the durability and performance of the plunger rod.

Preventive maintenance program

Implementing a preventive maintenance program, including regular inspections of the hydraulic system, lubrication system, and the mechanical condition of the plunger rod, can significantly reduce failure rates and extend equipment life.

Optimized design

The performance and reliability of the plunger rod can be further improved by optimizing its design (such as adding cooling channels or improving water flow).

Die casting machine plunger rod maintenance requires comprehensive consideration of lubrication, cooling, material selection, regular inspection and optimized design to ensure efficient operation of the equipment and product quality.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.