Die casting Mold Manufacturing Process involves precision machining and heat treatment to create durable molds for high-volume production.

Dye casting is an important industrial process for making detailed and accurate metal parts in bulk.

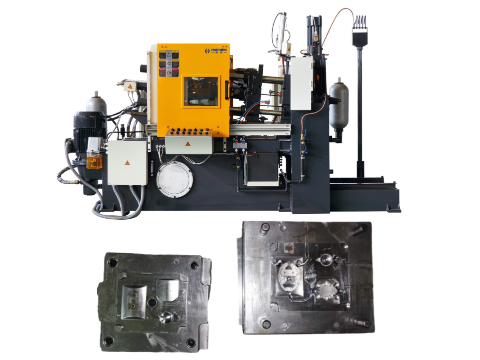

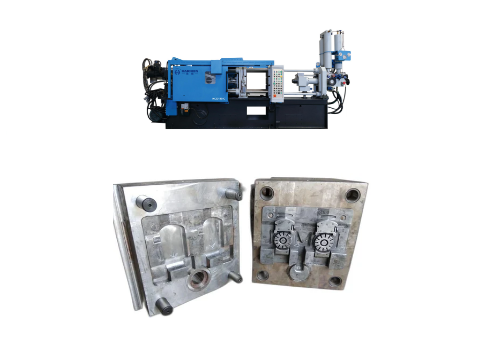

Integrating a die casting machine with a die casting mold is essential for maintaining the quality and character of the parts.

This essay will focus on the essential processes and fundamentals of making die casting molds.

The Core Value and Manufacturing System of Die-Casting Dies

The primary component in forming die-casting dies is these molds. Their layout design and construction quality is crucial for maintaining molding precision, production optimization, and the longevity of the machine. The equipment, die-casting mold, and process design must be cohesive in modern die-casting dies as an ‘equipment-mold-process’ die-casting machine triad.

Reliability on die cycles must exceed 100 000, alongside diameter stability of ± 5 °C and Ra surface accuracy of 0.8μm in one or more of the design structures which can be a melting cup, core pull, or hot runner.

Design and Engineering

Design Concept

The first stage of constructing a die casting mold includes coming up a with a detailed concept design. Engineers create 3D CAD models of production components, incorporating dimensions 0.1 mm plus/minus, a surface finish of Ra 0.8-3.2, and other functional needs. The design needs to consider draft angles, surface parting lines and parting lines, and gating so that the mold fills and ejects correctly.

Simulation and Analysis

Engineers simulate and analyze air mold designs using software like Moldflow to simulate and analyze the air pockets, short shots, and risks of mold warpage before any steel is actually cut to mold designs, therefore stock is spared. They also save resources by simulating to minimize the number of physical prototypes that are made.

Material Selection

Mold Steel

To maximize mold durability and performance, the steel that is chosen is a determining factor. Mold makers like using H13/S7 tool steel, due to the 50-54 HRC hardness, 3 times longer wear resistance than typical steel, and thermal stability up to6 00 degrees. The decision on what type steel to use is based on what the part needs and the targeted production output.

Surface Treatment

They achieve a 300% increase in service life and reduce downtime by applying surface treatment processes like nitriding or hard chrome plating to important components of the mold. These treatments improve the mold’s resistance to wear and corrosion, ensuring consistent part quality over a longer production run.

Machining and Assembly

CNC Machining

Toolmasters utilize 5-axis CNC machines to surpass the ±0.002mm positioning accuracy needed for critical surfaces. They can also meet the tolerances required for die casting molds, thus matching the design specifications. Toolmakers separately machine 5-axis CNC milled cavities and cores, then assemble them and achieve 0.01mm alignment accuracy.

EDM (Electrical Discharge Machining)

EDM can be employed to attain the intricate detail needed with tight tolerances. This eutectic method of machining uses electrical discharges to form a complex shape. The method edward sculpts the mold with fine detail that cannot be made with normal machine tools.

Assembly and Fitting

The assembled components of the machine go through a complete mold test. This test inspects the placement of mold halves to ensure they come together seamlessly, correcting any issues such as flash or lines that are parted. The mold then undergoes a secondary test to ensure each function of the machine is operating as intended.

Testing and Validation

Initial Testing

Mold testing and validation is crucial, for errors can be exponentially costly. Parts are checked for dimension accuracy, defect, and surface along with the design parameters set during the testing phase with injected molten components.

Quality Control

In terms of manufacturing, quality control is one of the most important steps in the process. The quality team uses CMM machines for dimensional control of ±0.01mm in their quality assurance process. They also use white light scanners for 0.1μm surface scanning and sectioning examinations for surface and internal scanning. The tooling team makes the necessary changes and modifications to the mold.

Maintenance and Upgrades

Regular Maintenance

Routine Maintenance In terms of production of high-quality parts, the mold must be maintained and serviced regularly. This includes cleaning, inspecting, and lubricating the internal and external parts of the mold. Maintenance personnel take action to repair parts of the mold which have been excessively worn down or damaged, in order to eliminate defects in the cast pieces during production.

Upgrades and Repairs

After sometime, the mold needs some upgrades or repairs in order to perform tracks. This includes the replacement of worn parts, surface conditioning and modifications to the mold to suit the changes in design of the component.

HAICHEN Mold Manufacturing Practice and Case Study

HAICHEN uses a complete in-house system for mold making. This system links design, machining, and testing to make molds that work well for fast and stable production. Below is an example from a project for a new energy vehicle motor housing mold.

- Test Molds and Quick Adjustments

- Working Together on Design and Simulation

- Precise Machining and Surface Treatment

Test Molds and Quick Adjustments

We tested the mold on our own big die casting machines. Our machines tracked the injection pressure and mold temperature in real time. We compared this data with our earlier simulations. The first test parts were scanned and measured. Our team then made two quick rounds of small changes to the mold in two weeks, mainly for better cooling and air escape. The third test run already met all quality standards for mass production. This cut the total mold development time by about 30%.

Working Together on Design and Simulation

Our engineers worked closely with the client on the mold design. The part had thin walls and deep sections. We used simulation software to study how the metal would flow and cool. We changed the gate and cooling channel design many times. This lowered the risk of air traps by 70% and made the mold heat more even.

Precise Machining and Surface Treatment

We used 5-axis milling and fine wire cutting to make the mold cores and cavities. Key areas kept an accuracy of ±0.003mm. For parts that get very hot and worn, like the sprue area, we used special coatings. This made the surface much harder, so it lasts longer against heat and wear.

HAICHEN: Your Partner in Die Casting Solutions

At HAICHEN, we focus on the design and manufacture of die casting machines. Their purpose is to meet the high and uncompromising standards relating to precision and reliability. They have been design to function in synergy with die casting molds of equally superior quality, facilitating consistency in production efficiency and quality. In the manufacturing of automotive parts, aerospace components, or other products with high precision, HAICHEN avails the necessary tools and expertise to assist in achieving production targets.

Why Choose HAICHEN?

- Advanced Technology: All of our die casting machines incorporate advanced control technoligies and quality components in order to produce machines of the utmost quality.

- Custom Solutions: Custom configurations are available based on unique customer criteria such as the volume of the molds, the types of raw materials, and even the materials that are use in the machine.

- Quality and Reliability: HAICHEN machines are ensured to meet outstanding conditions of quality and reliability therefore providing automated, steady and uninterrupted functionality.

- Comprehensive Support: Our commitment to customer satisfaction includes comprehensive after-sales support, technical assistance, and maintenance services.

The die casting mold manufacturing process is a complex and critical part of the die casting industry. From design and engineering to machining, assembly, testing, and maintenance, each step plays a vital role in ensuring the production of high-quality, consistent cast parts.