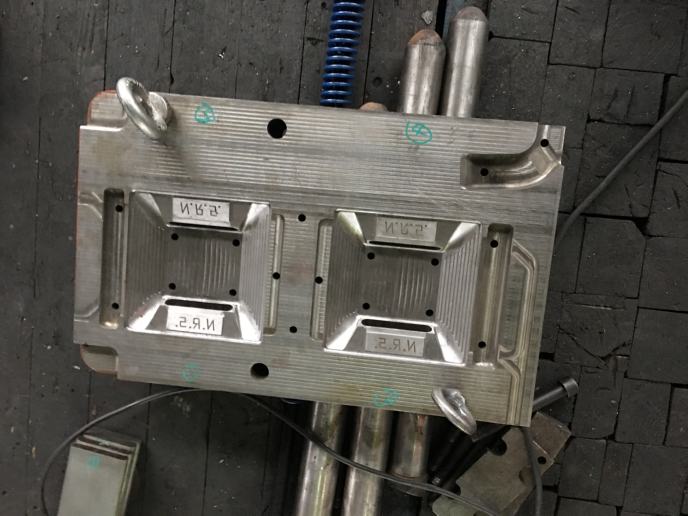

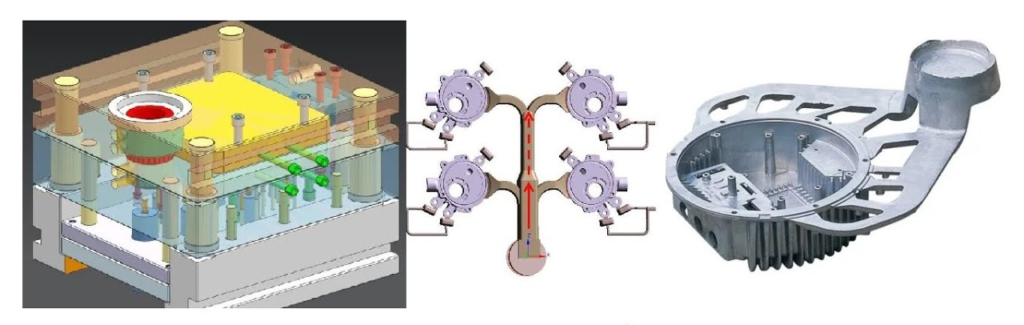

The selection and application of die casting mould material is of critical importance in modern manufacturing.Die casting transforms visions into reality, enabling the precise creation of complex metal parts that are the backbone of today’s leading industries, from automobiles to electronics. At the heart of the process is the high-pressure injection of molten metal into finely crafted moulds, laying the foundation for innovation and design excellence.

Die casting mould material and application level of high and low, directly feel all kinds of die casting product quality and production efficiency. Can be said to be the most basic quality assurance of die-casting process.

Because they directly affect the performance and life of the mould and the quality of the final product.

Die casting mould Common materials and their characteristics

- Aluminium alloy

- Steel

- Copper alloy

Aluminium alloy:

Die casting mould material and application level of high and low, directly feel all kinds of die casting product quality and production efficiency. Can be said to be the most basic quality assurance of die-casting process.

Aluminium alloy is widely used in die-casting moulds under high temperature conditions because of its low density, good mechanical properties and high thermal conductivity. Commonly used aluminium alloy die casting mould materials include 3Cr2W8V, 3243, H13 and so on.

These materials have high strength, wear resistance and resistance to thermal fatigue.

It is suitable for manufacturing complex die castings, such as automotive parts and electronic product shells.

Steel

Steel materials such as H13 and SKD61.

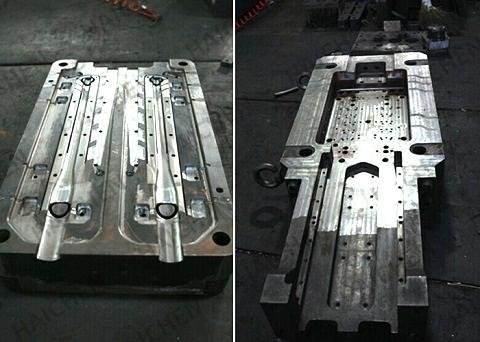

are commonly used to make large die casting moulds because of their high strength and wear resistance.

These materials can withstand high temperature and high pressure cyclic impact.

Suitable for the production of large or precision die castings.

Copper alloy

Copper alloys have excellent thermal conductivity and corrosion resistance, and are suitable for occasions where mould accuracy and stability need to be maintained.

Commonly used copper alloy materials include 4Mo5Cr4V2Mo5, etc. These materials perform well in high temperature environments.

Haichen specialises in providing high-quality die-casting machines and moulds, dedicated to creating precise and efficient products. Our machines are equipped with advanced features to ensure stable performance and produce high-quality output. Whether you are establishing a new production line or upgrading existing equipment, Haichen can provide solutions tailored to your requirements.

Die casting mould Application of special materials

- Non-metallic materials

- Coating technology

Non-metallic materials

With the development of technology, non-metallic materials such as ceramics and carbides are gradually used in die casting moulds.

These materials have the advantages of light weight, high strength and corrosion resistance.

Can effectively avoid the traditional metal materials in the high temperature and high pressure is easy to rust and thermal expansion of the problem.

Coating technology

In order to improve the service life and performance of the mould, coating technology is also widely used.

For example, PVD (Physical Vapor Deposition) coating can significantly improve the wear resistance and chemical stability of the mould.

Key factors for Die casting mould material selection

- Working temperature and pressure

- Cost and economy

Working temperature and pressure

Different materials have different tolerance to temperature and pressure.

For example, aluminium alloy moulds perform well at high temperatures, but their strength is relatively low.

Steel moulds, on the other hand, have high strength but are prone to deformation at high temperatures.

Cost and economy

The choice of material also needs to consider the cost factor.

Although, for example, H13 steel has high performance, its price is high.

So in some cost sensitive applications go for other materials.

Future trends

- New Material Development

- Intelligent and automation

New Material Development

As industrial demand rises, more high-performance materials for die casting moulds may appear in the future.

By optimising the proportion of alloying elements or developing new coating technology, the durability and productivity of moulds will be further improved.

Intelligent and automation

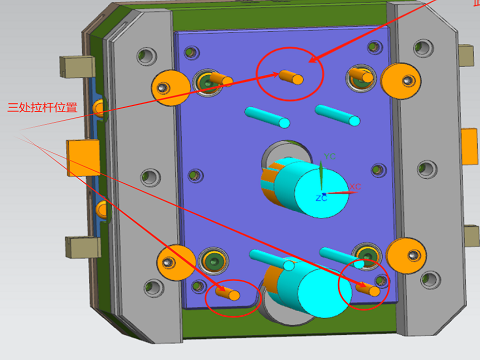

With the development of intelligent manufacturing technology, the design and manufacturing process of die casting mould will be more automated and precise.

Thus further improving the performance and service life of the mould.

Die casting mould material selection need to comprehensively consider the material performance, cost, working environment and future development trend.

Through reasonable selection and optimisation of mould materials, can significantly improve product quality and production efficiency.

Die cast mould steel materials for special applications

Die casting mould steel materials have special applications in die casting mould manufacturing.

Steel moulds give strong quality support to the die-casting industry

The special advantages of steel mould materials are mainly reflected in the following aspects:

- High temperature resistance

- Resistance to thermal cracking

- Wear resistance and corrosion resistance

- High toughness and strength balance

- Special alloy design

- The application of new materials and technology

High temperature resistance

Die casting moulds need to withstand extremely high temperatures in the process of use.

For example, the working temperature of aluminium alloy die casting mould can reach 600-700℃.

Therefore, the mould steel must have excellent high temperature strength and heat resistance.

The 1.8433 mould steel we use for copper die casting moulds shows significant advantages.

Its heat resistance is about 2 to 3 times that of traditional mould steel such as H13, and its high thermal conductivity contributes to rapid heat dissipation, thus prolonging the life of the mould.

Resistance to thermal cracking

Due to the die casting process metal liquid high-speed impact mould cavity, mould material is easy to produce thermal cracks.

For this reason, Haichen has developed new mould steels such as DAC-XTM.

By optimising the alloy design and heat treatment process, the thermal cracking resistance of the material is improved, thus prolonging the life of the mould and increasing the production efficiency.

Wear resistance and corrosion resistance

Die casting mould in the process of use will be subject to high-speed flow of liquid metal scouring and corrosion.

Therefore, the mould steel needs to have good wear resistance and corrosion resistance.

Haichen die casting mould using PVD (physical vapour deposition) technology treatment of mould steel surface can form a layer of wear-resistant coating, further improve the service life of the mould.

High toughness and strength balance

In order to meet the production needs of complex die castings, mould steel needs to be balanced between high strength and high toughness.

DAC series mould steel through improved composition and heat treatment process, achieve a good balance of high temperature strength and toughness, suitable for large die casting moulds.

Special alloy design

For different die casting materials (such as aluminium alloy, magnesium alloy, etc.), die steel need to carry out specific alloy design to adapt to its characteristics.

Through the optimisation of alloy composition and heat treatment process, can significantly improve the service life and performance of the mould.

The application of new materials and technology

In recent years, we continue to develop new die casting mould steel materials and introduce advanced manufacturing technology.

By reducing the sulfur content in the steel, optimising the forging process and using RE (rare earth elements) to change the inclusions morphology and other methods to improve the overall performance of the die steel.

Die casting mould steel material special application mainly focuses on improving high temperature resistance, resistance to thermal cracking, wear resistance and corrosion resistance, etc., in order to meet the die casting process on the mould material of the stringent requirements.

These characteristics make die casting mould steel in automotive, electronic products, plastic products and other fields have been widely using.

Special applications for aluminium materials for die casting moulds

Aluminium alloy die-casting mould material has distinctive characteristics and an extremely wide range of applications.

Aluminium material in the modern die-casting industry has a variety of special applications, especially in the automotive, aerospace, electronic equipment and other fields.

The following are its main special applications and related characteristics:

- Light weight and high precision

- Corrosion resistance

- High thermal conductivity and thermal stability

- Complex shape and high precision processing

- Heat fatigue and wear resistance

- Environmental protection and energy saving

Light weight and high precision

Aluminium alloy die casting mould material because of its low density and high strength characteristics, is widely used in the need for lightweight and high dimensional accuracy in the manufacture of parts.

In addition in the automotive industry, aluminium alloy die casting using in the manufacture of engine block, cylinder head and transmission housing and other components.

These parts not only reduce the weight of the vehicle, but also improve fuel efficiency and performance.

Corrosion resistance

Aluminium alloys have good corrosion resistance, making them particularly suitable for equipment used in chemically corrosive environments.

High thermal conductivity and thermal stability

The high thermal conductivity and good thermal stability of aluminium alloy make it an ideal mould material.

Aluminium alloy die castings are common in the manufacture of heat sinks, mobile phone housings, LED light housings, etc. These applications require materials that can effectively dissipate heat and maintain structural stability.

Complex shape and high precision processing

Aluminium alloy die casting mould material can produce complex shapes and consistent size parts through high pressure die casting process.

This process is particularly suitable for high-volume production, while ensuring smooth surfaces and high precision.

For example, aluminium alloy die casting parts are widely using in the manufacture of automobile parts, motorbike parts and precision instruments.

Heat fatigue and wear resistance

Aluminium alloy die casting mould materials usually need to have excellent thermal fatigue resistance and wear resistance, in order to cope with high temperature and high pressure working environment.

For example, 45CrMo2V and other alloy steel is used in the manufacture of heat damage resistance die casting mould, in order to extend the life of the mould and improve production efficiency.

Environmental protection and energy saving

Aluminium alloy die casting process is more environmentally friendly and energy saving compared to traditional casting process.

Aluminium alloy recycling rate is high, and in the production process of low energy consumption.

This makes the aluminium alloy die casting mould material become in line with the modern industrial sustainable development requirements of the manufacturing method.

Aluminium alloy die casting mould material with its lightweight, high strength, corrosion resistance, high thermal conductivity and complex shape processing ability, widely using in many fields, and with the progress of technology, the scope of its application is still expanding.