Disadvantages of Die Casting Overflow include material and resource waste, impurity recovery issues, negative impact on mold life. Product quality defects are also disadvantages of die casting overflow.

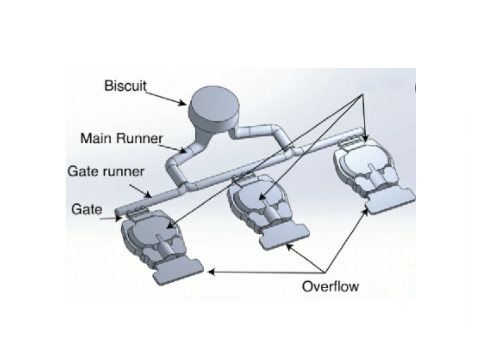

Die casting overflow grooves play an important role in improving casting quality.

Exhaust and thermal balance, there are many shortcomings in their design and application.

Waste of materials and consumption of resources

The overflow system has a high volume ratio

The volume of the overflow and gating system usually accounts for 20%-50% of the shot volume.

Especially in thin-walled castings, where the proportion of material in the overflow is higher.

Workers must remelt and dispose of these materials.

Which consumes additional energy (e.g., electricity) and generates material loss (e.g., oxide slag).

For example, the material of the overflow system can account for more than 40% of the total shot volume in thin-walled castings.

Cold metal and impurity recovery issues

The low-temperature metals or impurity-containing metals.

Such as oxides and paint residues received by the overflow tank are difficult to reuse directly.

And they need to undergo complex treatment before they can be put back into production.

Which increases the treatment cost.

Negative impact on mold life

Thermal stress and mold erosion for disadvantages of die casting overflow

The design of the overflow groove directly affects the thermal balance of the mold.

If the overflow area is locally overheated (e.g., the metal flow rate is too fast).

The thermomechanical stress on the mold surface will be exacerbated, resulting in thermal fatigue cracking (Heat Checking) or erosion.

For example, a study at the Mazzucconi foundry in Italy found that cooling channels near the overflow chute that were too far from the mold surface significantly shortened the mold life.

Mechanical wear and washout

Improper design of the overflow (e.g., too wide or too thick) can cause high-velocity metal streams to wash the mold surface.

Accelerate wear of the cavity or vent groove, and even cause die washout defects (Die Washout).

Product quality defects

Stomata and shrinkage porosity

When the overflow system is not exhausted sufficiently, the gas tends to be trapped in the cavity and form porosity.

In addition, if the overflow tank solidifies prematurely, it cannot effectively discharge the front-end gas, resulting in shrinkage in critical areas of the casting.

Inclusions and reflux contamination

Cold metal or impurities in the overflow can flow back into the cavity through the overflow port.

Causing Inclusions or Flow Marks inside the casting.

For example, if the position of the overflow and exhaust grooves does not match.

The cold liquid can clog the exhaust channel, resulting in impurities remaining.

Surface defects and dimensional deviations

Excessive overflow velocity can cause metal splashes, form flashes at the parting line.

Or cause scratches and uneven texture on the casting surface.

Constraints on production efficiency

Extended production cycles

Poor design of the overflow system can lead to longer filling times or frequent downtime to clean residues in the overflow tank.

For example, in the case of die-casting of a gearbox housing, the production cycle time was reduced by 15 percent after the overflow system was optimized.

Commissioning and maintenance costs increase

Complex overflow systems require more commissioning time.

And molds require frequent maintenance due to thermal stress or washout, further reducing equipment utilization.

The cost of the economy is rising

Mold design and processing costs

The optimal design of the overflow system requires numerical simulation (e.g., ProCAST, MAGMASOFT) and experimental verification, which increases the mold development cycle and cost.

For example, an oil pump cover mold used simulation to optimize the layout of the overflow groove, reducing development costs by 20%.

Material and energy costs

Material waste in the overflow system directly increases the cost per part.

In the case of aluminium alloys, the cost of handling returns increases by about $200-300 per ton.

Environmental & Sustainability Impacts

The high proportion of overflow material re-furnace treatment not only increases carbon emissions (melting process), but can also lead to metal oxidation losses and affect resource utilization.

Studies have shown that optimizing the overflow design can increase the material utilization rate by 10%-15%, which indirectly reduces the environmental burden.

Improvement direction and technical optimization

Integrate mold flow analysis with intelligent design

The flow and temperature field of molten metal are simulated through ProCAST, FLOW-3D and other software.

And the position and size of the overflow tank are optimized to reduce the number of mold trials.

Vacuum die casting technology

Combined with a vacuum system for forced venting, it reduces reliance on overflow grooves, reduces scrap rates and improves surface quality.

Gradient Materials & Coating Techniques

Use heat-fatigue resistant H13 steel or surface nitriding treatment in the overflow groove area to extend mold life.

Modular overflow design

The replaceable insert structure is easy to maintain and adjust, and reduces the overall mold scrap rate.