Shot sleeve reconditioning features need to be analyzed from multiple dimensions such as fault type, repair process, material selection, and performance testing.

After all, the die-casting injection sleeve is the core component of the die-casting machine to transfer the molten metal to the mold cavity.

Which is prone to wear, deformation, cracks and other faults due to high temperature, high pressure and molten metal erosion for a long time.

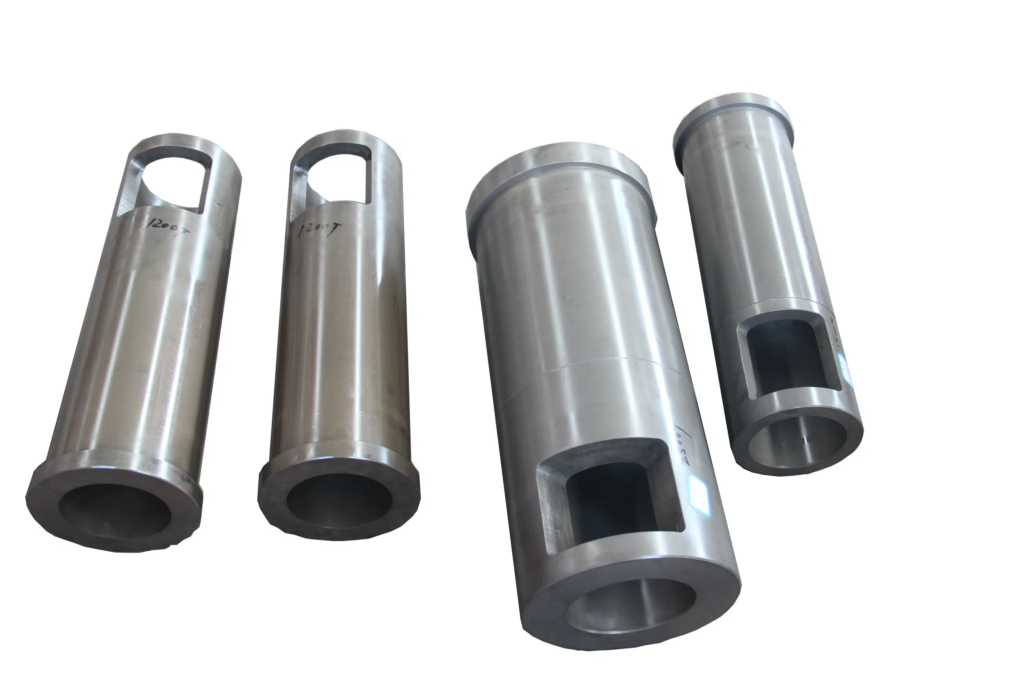

The structure of the injection sleeve and the common types of failures

Structure and function

The injection sleeve is a hollow tubular structure, which connects the injection mechanism of the die-casting machine with the mold.

And needs to maintain high-precision cooperation with the injection punch (hammer) and gate sleeve.

The inner cavity is responsible for holding the molten metal and filling the mold cavity by plunger injection.

Common types of faults

Inner wall wear and erosion

The high-speed flow of molten metal leads to wear on the surface of the feed port and inner hole, which affects the tightness (such as flying material).

Deformation and cracking

Bending or cracking of the sleeve caused by excessive ejection force or insufficient stiffness of the sleeve (e.g., spraying).

Abnormal fitting clearance

The injection head is not the same shaft as the sleeve, and insufficient cooling leads to jamming or strain.

Thermal fatigue damage

Repeated thermal stresses lead to degradation of material properties, resulting in localized spalling or microcracks.

Repair process methods and technical difficulties

Mounting restoration

Applicable scenarios: inner wall wear or ovality out of tolerance.

Process steps

After reaming, workers embed a new sleeve (semi-finished product).

They fix it with an inorganic adhesive (such as copper oxide-phosphate glue) to restore the inner hole’s accuracy.

Difficulty

The adhesive surface of the old and new sleeves needs to be highly clean.

And the wall thickness and strength need to be guaranteed after reaming.

Plating repair technology

Plating process

Iron plating, chrome plating or hard chrome plating is used to repair the wear of the inner wall and improve the wear resistance.

Flame spraying

Suitable for local damage, but it is necessary to choose a high-temperature resistant coating.

Such as tungsten carbide and control the spray thickness.

Difficulty

The bonding strength and uniformity of the coating are required to be high, and the coating needs to be avoided.

Welding sleeve repair

A-type sleeve

Used for small defect repair, reinforced by welding of two semi-circular guard plates, simple operation but limited pressure capacity.

Type B sleeve

Suitable for high-pressure or annular defects, workers must weld the annular seam and longitudinal seam, and then verify the weld quality through non-destructive testing (UT, MT) after repair.

Difficulty

Hydrogen-induced cracking

The hydrogen source (e.g., pre-cleaning, low-hydrogen electrode) and cooling rate need to be controlled during welding.

Burn-through risk

In-service pipe welding needs to balance the heat input to prevent pipe wall rupture caused by excessive penetration.

Composite repair process

Carbon fiber or glass fiber reinforced epoxy resin is used to wrap or wrap the defective parts, and form a high-strength reinforcing layer after curing.

Advantages

Lightweight, corrosion-resistant, suitable for complex geometries.

Difficulty

Engineers must ensure strong bonding between the fiber and matrix material, and precisely control the construction process (such as vacuum infusion).

The core approach to the refurbishment process

Replaceable bushing technology in the wear area

For localized erosion of the inner wall of the injection tube, Castool and other manufacturers offer replaceable plug-in bushings (e.g., H-13 material combined with 3P coating).

To enhance surface hardness (HV up to 1000-1200) through nitriding post-treatment to reduce the adhesion of molten metal.

For example, a double-layer design (e.g., the outer layer of Sialon Engineered Ceramic Layer) maintains temperature stability while extending the overall life by replacing the inner layer.

Thermal Spray Repair

Plasma spray or flame spraying techniques are used to coat high-performance alloys.

Such as tungsten carbide or zirconia, over wear areas to repair surface defects and improve wear resistance.

For example, although the zirconia coating failed in the early application due to adhesion problems, the improved process has been able to significantly extend the life.

Nitriding treatment

Through ionic nitriding or gas nitriding, a dense nitriding layer is formed on the surface of the injection tube, reducing the adhesion of molten metal and thermal fatigue cracks.

Experiments have shown that the injection force is reduced by 20-30% and the life span is increased by more than 30% after nitriding treatment.

Geometric accuracy restoration and thermal deformation control

Use simulation tools, such as Castool’s simulation software, to predict the amount of deformation of the injection tube at high temperatures.

And restore its roundness (tolerances to ±0.05mm) and straightness through machining (e.g. grinding or boring).

For elliptical deformation caused by temperature gradients (the bottom temperature is 100-150°C higher than the top).

The cooling system design (water-cooled or oil-cooled) is optimized to ensure that the temperature difference does not exceed 50°C.

Repair Material Selection

Criteria Wear resistance

Die steel (e.g. H13), stainless steel or ductile iron (tensile strength≥ 550 MPa) is preferred.

High temperature resistance

The working temperature needs to withstand more than 600°C to avoid thermal softening.

Corrosion resistance

Resistant to chemical attack by molten metals (e.g. aluminium alloys), chrome plating or oxidation can provide added protection.

Plating technology

Chrome plating to improve surface hardness (HV≥800), nickel plating to enhance corrosion resistance.

Oxidation treatment

Blackening or oxidative dyeing to form a protective film to reduce the coefficient of friction.