Die Casting Spray Nozzle Manufactuer including well-known enterprises both at home and abroad:

- Dongguan Shaou Spray System Co., Ltd.

- Dongguan Feihuang Hardware Products Co., Ltd.

- Guangzhou TEDA Environmental Control Equipment Co., Ltd.

- Shenzhen Jiuyang Electromechanical Co., Ltd.

- Dongguan Chengda Machinery Parts Co., Ltd.

- Shanghai Lezhou Machinery Parts Co., Ltd.

- Guangdong Tiandi Automation Machinery Co., Ltd.

- Dongguan Yaoshun Spray Technology Co., Ltd.

- Haichen Machinery

- Maschinenbau BÖHMER GmbH

- Sunrise Metal Die Casting Spray Nozzle Manufactuer

- PNR Corporation Die Casting Spray Nozzle Manufactuer

- IKEUCHI

These companies occupy an important share in the global Die Casting Spray Nozzle market and maintain their competitiveness through technological innovation and product differentiation.

The customer reviews and industry reputation of these die-casting nozzle manufacturers are generally positive.

They are recognized for their high-quality products, advanced technology and excellent customer service.

Die casting nozzles

Die casting nozzles are a key component used in the die casting process to spray molten metal or alloy into the mold through high pressure.

In the die casting process, the role of the nozzle includes ensuring uniform filling of the molten metal, controlling pressure and speed.

And preventing the molten metal from coming into direct contact with the mold that can lead to adhesion.

Dongguan Shaou Spray System Co., Ltd.

The company provides die-casting machine manipulator nozzles, high-pressure die-casting accessories, servo atomizer nozzles and other products, with a 10-year business history and 7-day replacement service.

Dongguan Feihuang Hardware Products Co., Ltd.

The company produces lumina rosin wave soldering nozzles, flux release agents, die-casting blister machines, anti-drip fan humidification nozzles and other products, with a business time of 5 years.

Guangzhou TEDA Environmental Control Equipment Co., Ltd.

The company provides automatic spray heads for Japanese ST-5 die-casting machines, which have good spraying effects.

Shenzhen Jiuyang Electromechanical Co., Ltd.

The company sells AW-2R Fuso Seiki Japan LUMINA nozzle nozzles, which has been in operation for 12 years.

Dongguan Chengda Machinery Parts Co., Ltd.

The company provides die-casting machine spray heads directly supplied by the factory, the brand is Chengda Machinery, and the business time is 8 years.

Shanghai Lezhou Machinery Parts Co., Ltd.

The company produces many types of nozzles, including nozzles, fan-shaped nozzles, spiral nozzles, plastic nozzles, atomizing nozzles, etc., with an annual turnover of between 20.01 million and 30 million.

Guangdong Tiandi Automation Machinery Co., Ltd.

The company is located in Chang’an Town, Dongguan, Guangdong Province, and its main products include industrial nozzles, spray guns, spray systems, etc., and have entered related fields since 2006.

Dongguan Yaoshun Spray Technology Co., Ltd.

The company specializes in the production and processing of nozzles, spray guns, spray systems and other products, and has a complete and scientific quality management system.

Shanghai Weizhu Machinery Manufacturing Co., Ltd.

The company supplies die-casting machine accessories, including nozzle tubes, nozzle bodies, nozzle tubes, nozzle heads, etc., with a business time of 14 years.

Maschinenbau BÖHMER GmbH

A company specializing in the design and manufacture of customized special equipment for the automotive industry, including the design and manufacture of nozzles.

The company offers nozzles for a wide range of spraying applications, including mold cooling and coating.

Sunrise Metal Die Casting Spray Nozzle Manufactuer

Mold spraying and lubrication technology in its mold casting operations to increase productivity and reduce defects.

PNR Corporation Die Casting Spray Nozzle Manufactuer

This company offers nozzle products and technical information for a wide range of industrial applications, and its catalog describes the different types of nozzles and their performance characteristics in detail.

IKEUCHI

A Japanese manufacturer of industrial nozzles and humidification systems, known for its ceramic nozzles and offering atomizing and spraying products.

Lechler offers nozzle systems for aluminium processing, which are used for cooling, lubrication, and other processes in aluminium machining.

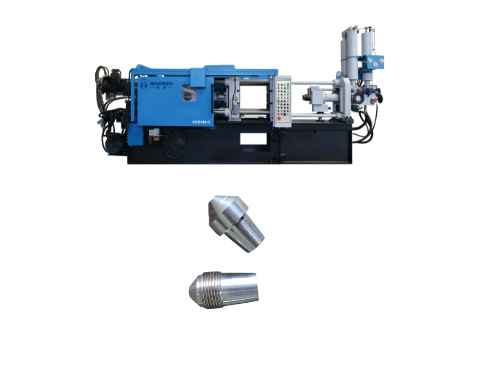

Haichen Die Casting Spray Nozzle

- Types and Functions

- Technical Features and Advantages

- Applications and Application Fields

- Market and Product Information

Types and Functions

Nozzle Types: Haichen offers a wide range of die-casting nozzles.

Each unique design caters to the requirements of different molds and casting processes.

Functions: Nozzles inject molten metal into mold cavities and spray mold release agents to enhance cooling and mold release efficiency.

Servo-driven nozzles improve product consistency by precisely controlling the injection volume and position.

Technical Features and Advantages

Servo-driven Nozzles: Haichen’s servo-driven die-casting nozzles use servo motors to drive operation.

They can accurately control injection parameters, reduce mold release agent consumption, and boost production efficiency and product consistency.

Materials and Design: Some nozzle models adopt high thermal conductivity or wear-resistant materials, which effectively extend their service life.

Automation and Intelligence: Modern nozzles integrate sensors and advanced control systems, making them well-suited for intelligent production needs.

Applications and Application Fields

Application Scope: Die-casting nozzles are widely used in die-casting processes for magnesium alloys, aluminum alloys and other materials, fulfilling the functions of cooling, mold release agent spraying and molten metal injection.

Industry Demand: As the manufacturing industry moves toward higher efficiency and automation, the market demand for high-performance nozzles keeps growing.

Market and Product Information

Commercial Products: The market provides various nozzle models and accessories, including SD-13/SD-14 nozzles and servo-driven nozzles, with prices ranging from a few yuan to several hundred US dollars.

Patents and Innovations: Some of Haichen’s patented nozzle technologies focus on structural optimization and material improvement, which further enhance nozzle performance.

With a pressing force of 160 to 2080 kN, Haichen’s HCD-C and HCD-H die casting machines are robust and equipped with excellent control systems to provide flexible and efficient production.

In addition to die-casting machines, Haichen also provides various accessories and auxiliary machines.

This includes die-cast nozzles, mechanical hands, etc.

Moreover, Haichen also offers a warranty period and free maintenance and replacement services.

For more details, please consult.

The latest technological advances in die casting spray nozzle manufactuer

- Micro spraying technology

- Delta Speed micro nozzle from WOLLIN, Germany

- Nanjing Litai’s lubrication device nozzle patent

- Modular design and technology upgrade

Micro spraying technology

Micro spraying technology is one of the best spraying methods that has been widely recognized and promoted in recent years.

Representing the latest development trend of die casting spraying technology.

This technology achieves efficient, high-quality spray results by precisely controlling spray pressure.

Flow and release agent composition, effectively extending mold life and reducing production costs.

Delta Speed micro nozzle from WOLLIN, Germany

As a pioneer in micro spraying technology, German WOLLIN uses Delta Speed micro nozzle.

Which adopts a fixed volume to control the amount of spraying.

And the micro motor feeds at a uniform speed during spraying, and each nozzle can be independently programmed and controlled.

This technology can increase the production capacity of die castings.

Reduce the amount of dilution water and wastewater, extend the life of the mold, and significantly reduce costs.

Nanjing Litai’s lubrication device nozzle patent

Nanjing Litai Intelligent Technology Co., Ltd. has obtained a patent called “a lubrication device nozzle”.

The patent realizes the communication between the inside and outside of the nozzle by setting a pressure valve plate and a pressure bolt inside the nozzle.

And sprays the material liquid in combination with the open sealing door.

When the liquid spraying is stopped, the reset spring pushes the pressure valve plate to reset.

And pushes the residual liquid inside the nozzle back to avoid leakage.

Modular design and technology upgrade

Shanghai Guchuan Co., Ltd. has developed a modular release agent atomizing nozzle.

Which has significant advantages in terms of flow, pressure, spray angle, coverage, impact force, temperature, material and application.

Its lightweight design of the aluminum alloy body, piston structure and independent control of three fluids ensure the durability of the product and low maintenance costs.

In addition, the modular design of the nozzles allows for customized distribution.

According to the shape of the part, which greatly saves assembly and maintenance time and improves production efficiency.