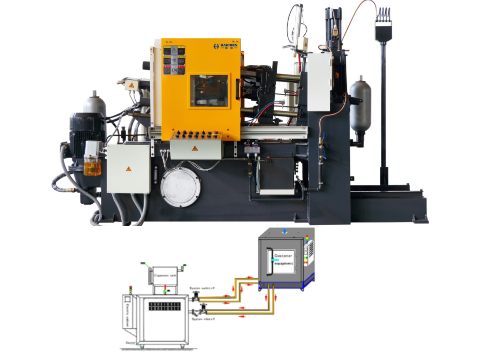

Die casting water mold temperature controller is a key equipment used to control the mold temperature in the die casting industry.

And its main role is to ensure that the mold maintains a constant temperature during the die casting process.So as to improve the quality and production efficiency of the casting.

Mold temperature controllers are widely used in the die casting industry, especially in the processes of cold chamber die casting and hot chamber die casting.

By precisely controlling the mold temperature, it is possible to ensure that the metal melts and flows adequately in the mold, improving the gradual quality and appearance.

Haichen will select the right machine for every customer who needs a mold temperature machine.

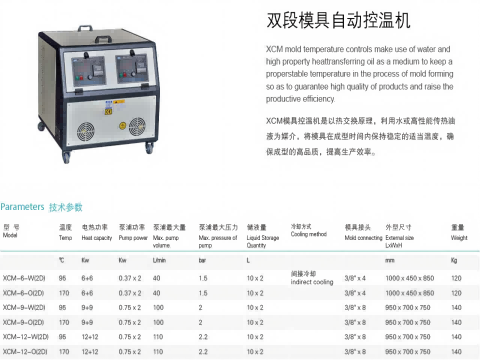

Mold Temperature Controller

As an essential auxiliary equipment, mold temperature controller has standard functions.Such as fast heating, stable temperature, and low water leakage.

It can meet the needs of industry customers for intelligent and digital upgrades, solve the temperature control problem of injection molding production.

And has a temperature control accuracy of ±0.1℃, which improves the temperature control efficiency by 10% and increases the service life by 40%.

- Fast heating

- Stable Temperature

- Low Water Leakage

Fast heating

Haichen’s mold thermometers are equipped with rapid heating capabilities. To meet the need for rapid response to temperature changes in the die casting process.

Stable Temperature

In addition, the temperature control accuracy and stability of the mold temperature machine. Accurate temperature control can shorten the production cycle and improve the consistency and stability of die casting components.

And the mold temperature machine ensures the stability and consistency of mold temperature through precise temperature control systems (such as PID control, microprocessor control) and high-precision sensors, reducing defects caused by temperature fluctuations.

Low Water Leakage

Haichen’s mold temperature machine pipeline is welded with stainless steel to heat evenly and reduce the risk of oil and water leakage, which can improve the reliability and safety of the equipment.

The working principle of the mold temperature machine

The working principle of the die casting machine mold temperature machine is mainly based on the basic principle of heat exchange and temperature control.

And its core purpose is to ensure the quality and production efficiency of die castings by precisely controlling the temperature of the mold.

The following is the specific working principle of the mold temperature machine:

- Mold heating system

- Heat transfer medium

- Temperature control system

- Safety Precautions

- Dual-circuit design

- Mold heating system

- Warm-up and cool-down functions

- Intelligent control

The mold temperature machine usually uses an electric heater or gas heater as a heat source to transfer heat energy to the mold through a heating tube or combustion chamber.

The temperature of the heater can be adjusted by the controller to achieve the desired mold temperature.

Heat transfer medium

The mold temperature machine uses heat transfer oil or water as the heat transfer medium and operates in a closed-circuit circulation system.

The heat transfer oil circulates under the action of a high-temperature magnetic pump, transferring heat from the heater to the mold

And then returning to the heater to continue heating, forming a circular process.

Temperature control system

The mold temperature machine is equipped with temperature sensors and control systems.

Such as PID controllers, which are used to monitor and adjust the temperature of the mold in real time.

When the mold temperature is lower than the set value, the heater starts.

When the temperature is higher than the set value, the cooling solenoid valve is opened.

So that the cooling water enters the plate changer.

And the heat is indirectly exchanged with the high-temperature heat transfer fluid, so as to reduce the temperature.

Safety Precautions

In order to ensure the safe operation of the mold temperature machine, safety measures such as liquid level, pressure and over-temperature protection are usually set.

The level controller monitors the oil level of the tank to prevent insufficient or excess oil.

The pressure controller prevents the heater from drying or clogging the pipes.

The over-temperature controller directly controls the mains power supply in the event of a heating contactor failure, preventing the danger of overheating.

Dual-circuit design

Some mold temperature machines use a dual-circuit design to control the temperature of the moving mold and the fixed mold separately.

This design allows for more precise control of the temperature of different parts

Improving the quality of die castings and the service life of molds.

Warm-up and cool-down functions

The mold temperature machine not only preheats the mold before production to reduce thermal stress and prolong the mold life.

But also keeps the mold temperature constant during the production process to ensure the stability of the size and density of the die casting.

In addition, the mold temperature machine can also maintain the mold temperature between productions.

Reducing energy consumption and speeding up the production schedule.

Intelligent control

Modern mold temperature machines are usually equipped with PLC intelligent operating system.

Which can display the technical parameters, temperature curve and operating status of the equipment in real time.

And support remote control and fault information display functions.

These intelligent features make the operation of the mold temperature machine simple and convenient.

And improve the service life and production efficiency of the equipment.

Mold Temperature Controller application

The specific applications and effects of mold temperature controllers in different alloy types are as follows:

- Aluminum alloy

- Magnesium alloy

- Zinc alloy

Aluminum alloy

Temperature range: The temperature of aluminum alloy die casting mold is usually controlled between 180-270°C.

Effect: By accurately controlling the mold temperature, it can effectively reduce problems such as cold lines.

In traditional production processes, mold replacement usually requires a long waiting time, and molds must be completely cooled before they can be disassembled and replaced.

The adoption of a high-temperature heat transfer oil circulation system can simultaneously address the preheating and cooling issues of molds and buffer the thermal shock of die-casting molds.

Improving the service life of die-casting molds also enhances the internal and surface quality of magnesium alloy die-castings and reduces the scrap rate.

It is highly suitable for molds of automotive connectors and any other custom components that require water or oil heating.

For instance, Haichen has selected such a mold temperature control unit in the production line of automotive gearboxes.

Magnesium alloy

Temperature range: The temperature of magnesium alloy die casting molds usually between 180-300°C.

Results: Precise control of the mold temperature is essential to guarantee the surface and intrinsic quality of magnesium alloy die castings.

Haichen’s mold temperature controller features forced cooling and timed on/off functions.

By continuously opening the cooling solenoid valve for cooling, the mold temperature can be reduced within approximately 10 minutes.

Preheating one hour in advance can increase efficiency by 10%, thereby significantly reducing mold changing time.

Zinc alloy

Temperature range: The temperature of zinc alloy die casting molds usually between 100-200°C.

Effect: Proper mold surface temperature distribution helps to improve production efficiency and product quality.

Improper mold temperature will lead to unstable casting size, resulting in thermal pressure, mold sticking, surface depression, shrinkage porosity and hot bubbles and other defects, affecting the production cycle and mold life.

Therefore, choosing the right mold temperature control unit is of great significance.

Haichen has repeatedly demonstrated this point in the mold solutions for zinc die-casting, whether in the design and production of door handles or MEDALS.

Haichen’s mold temperature machine

Haichen’s mold temperature machine can achieve precise control of the mold temperature

Ensuring that the flow of raw materials during processing is stable, thereby improving production efficiency.

It can realize functions such as intelligence, remote control, data transmission and intelligent analysis.

This intelligent upgrade enables the mold temperature machine to automatically adjust the heating temperature and time.

According to the preset temperature control formula, realize multi-stage temperature control, and greatly improve the production efficiency and product quality stability.