Difference between aluminum and aluminum alloys reflect in composition, performance comparison, applications and etc.,

Aluminum is a lightweight, corrosion-resistant pure metal suitable for general use. While aluminum alloys are suitable for more demanding application scenarios by adding other metal elements that significantly increase strength, hardness and corrosion resistance.

As metals go, aluminum is light and corrosion resistant. Making it suitable for general use. Other metal element additions most often enhance strength, hardness and corrosion resistance.

This alteration suited for more demanding application scenarios is why aluminum alloys exist. Choosing between aluminum and aluminum alloys completely depends on the application requirements and considerations of cost and benefit.

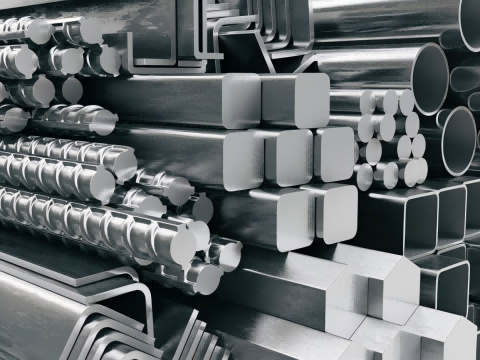

Different composition

Chemical different

Aluminium

- Aluminum is a pure metal with the chemical symbol Al and an atomic number of 13.

- It is a silvery-white, light metal with a high degree of purity (usually 99% or higher), and exists primarily as a monomer.

- For example, industrial-purity aluminum (Al99.5) has a purity of over 99.5%.

Aluminum Alloys

- They are made up of aluminum and other metallic elements such as copper, magnesium, silicon, and zinc.

- These are made by adding different elements to improve the physical and mechanical properties of aluminum, such as strength, hardness, corrosion resistance and electrical conductivity.

Physical Properties difference

Aluminum:

- Low density (about 2.7 g/cm³) and much lighter than steel, resulting in a high strength-to-weight ratio.

- Good electrical and thermal conductivity, good conductor of heat and electricity.

Resistant to atmospheric corrosion, but pure aluminum has a low modulus of elasticity and is less resistant to earthquakes.

Aluminum alloys

- These are usually less dense than pure aluminum, but their strength and hardness can be significantly increased by alloying. For example, the yield strength of 6061-T6 aluminum alloy is much higher than that of pure aluminum.

- They typically have a higher modulus of elasticity, making them suitable for applications requiring high strength and rigidity.

- Corrosion resistance is usually superior to pure aluminum, especially in marine environments.

Performance Comparison

Strength and Hardness

- Pure aluminum is soft and has low strength, making it unsuitable for high-load applications.

- The aluminum alloys significantly improve their strength, hardness, and durability through alloying, and some can be strengthened through heat treatment (such as 6061 and 7075).

Lightweight and Corrosion Resistance

- Both two offer low density and corrosion resistance (due to a surface oxide layer).

- While maintaining their lightweight advantages, aluminum alloys possess a specific strength (strength/density) close to that of high-quality steel.

Processing Characteristics

- Pure aluminum has good ductility but is easily deformed.

- Aluminum alloys offer a balance of properties (e.g., 6063 is easier to weld/form, 5083 is more corrosion-resistant), but are more difficult to recycle than pure.

Different Applications

Pure aluminum

- It used in conductive materials (such as cables), packaging (cans), and anti-corrosion coatings, relying on its high conductivity, corrosion resistance, and cost advantages.

Aluminum alloys

- Structural applications: Aviation (airframe components), automotive (frames), and construction (profiles), requiring a high strength-to-weight ratio.

- Engineering components: Complex parts (such as engine components) manufactured through die-casting/casting processes.

Processing difference

Processing Temperature and Equipment Requirements

Aluminum alloys

- Aluminium alloy requires a melting temperature exceeding 700°C (much higher than the 400°C of zinc alloys) and specialized die-casting equipment, which is not compatible with pure aluminum or other alloys.

Pure aluminum

- Pure aluminium has a lower melting point (approximately 660°C), requiring less energy to melt, making it suitable for continuous rolling or stretch forming.

Different Processing Forming

Pure aluminum

- Pure aluminum has excellent ductility and is suitable for cold working processes such as deep drawing and rolling, enabling it to be formed into thin foil or complex containers.

Aluminum alloys

varies depending on the type

- The aluminum alloys (such as 1050/1060) can be hardened by cold working, but high-strength alloys (such as 7075) require hot working (such as hot rolling) to prevent cracking.

- Cast aluminum alloys (such as Al-Si alloys) rely on die casting, and the silicon content improves fluidity but increases shrinkage.

Cost and Economy

Aluminum

- Pure aluminum is relatively low cost, but its limited strength and durability make it unsuitable for applications with high loads or extreme environments.

Aluminum Alloys

- This type alloys cost more than pure, but their performance enhancements make them more competitive in many high-performance areas.

- For example, these alloys in aerospace applications can significantly reduce structural weight and improve fuel efficiency.

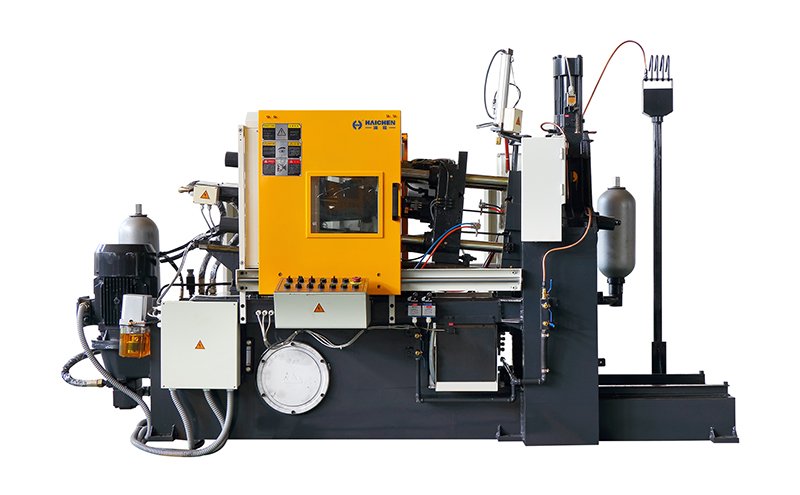

Haichen aluminium alloys die casting machine supplier

Haichen is a well-known manufacturer and supplier of aluminum die casting machines and related equipment. They specialize in providing high-quality, efficient, and reliable cold chamber die casting solutions for industries that require precision aluminum alloy components.

Our machines produce a range of die casting machines designed for this alloy and other non-ferrous alloys (e.g., magnesium, zinc). Besides cold chamber machine, we also supply hot chamber die casting machines. And our machines are widely used in industries such as automotive, electronics, aerospace, and consumer goods.

If there is any interest in our machines, welcome to consult us.