Difference between hot chamber and cold chamber die casting includes equipment structure, material suitability, production efficiency and so on.

Hot chamber die casting and cold chamber die casting are two common die casting processes, which have significant differences in equipment structure, material applicability, production efficiency and safety.

In this blog, we will analyse the difference between hot chamber and cold chamber die casting manily from below five aspects:

- Equipment structure

- Material suitability

- Production efficiency

- Safety and maintenance

- Product quality

Equipment structure

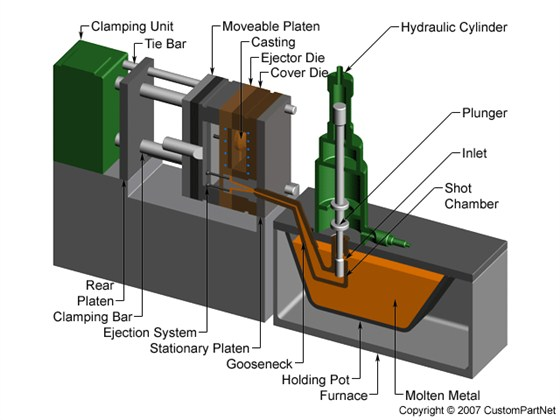

- Hot chamber die casting: The hot chamber die casting machine injects molten metal directly into the mold cavity. The molten metal stores in a molten pool inside the machine, and the metal injectes into the mold through a device called a “gooseneck”.

- This design makes the hot chamber die casting machine easier to operate, but it requires frequent cleaning of the residue in the mold.

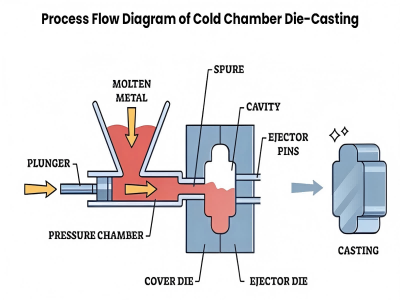

- Cold Chamber Die Casting: Cold chamber die casting machines require an external furnace to heat the metal. The molten metal introduces into the mold cavity through a pouring cup (gating system). Cold chamber die casting machines are usually used to process high melting point metals such as aluminum, magnesium and copper.

Integration of the Furnace and Shot Chamber

- Hot Chamber Die Casting

The shot chamber is integrated with the furnace, and the shot system (including the gooseneck) is directly immersed in the molten metal. - The molten metal is melted and maintained within the equipment before being automatically injected into the shot chamber through an internal channel.

- Advantages: Reduces heat loss during metal transfer, shortening production cycles.

- Disadvantages: The shot chamber is exposed to high-temperature metal for extended periods. Require the use of heat-resistant and corrosion-resistant materials (such as cast iron or tool steel), increasing maintenance costs.

- Cold Chamber Die Casting

The furnace is independent of the shot system and located external to the equipment. - Molten metal is transferred from the external furnace to the cold shot chamber by manual or automated scooping (e.g., robotic arms).

- Advantages: The shot chamber maintains a lower temperature, allowing for processing of high-melting-point metals (such as aluminum and copper alloys).

- Disadvantages: Heat loss during metal transfer increases production cycles and operational complexity.

Injection System Structure

- Hot Chamber Die Casting:

- A gooseneck structure directly connects the furnace and the mold cavity, enabling rapid injection of molten metal.

- The equipment is compact and occupies a small footprint, making it suitable for efficient production of small parts.

- Cold Chamber Die Casting:

- The injection chamber is an independent horizontal cylinder, with a piston pushing the molten metal into the mold. It lacks a built-in furnace and requires an external feeding system.

- This equipment is more complex and requires additional space for an external furnace and scooping device.

Temperature Control System

- Hot Chamber Die Casting

A built-in precision temperature control system directly regulates the temperature of the molten metal in the furnace, ensuring a stable die-casting process. - Suitable for low-temperature alloys (such as zinc and magnesium, with a melting point ≤ 450°C).

- Cold Chamber Die Casting

Temperature control relies on an external furnace. The shot chamber itself has no heating function, requiring rapid metal transfer to prevent solidification. - Designed specifically for high-temperature alloys (such as aluminum and copper, with a melting point ≥ 600°C).

Material suitability

Hot chamber die casting

Hot chamber die casting material is suitable for low melting point metals such as zinc, magnesium and tin. These metals have good fluidity and are easy to process, so hot chamber die casting is suitable for large-scale production.

Cold chamber die casting

Cold chamber die casting is suitable for high melting point metals such as aluminum, magnesium and copper. These metals have high melting points and poor fluidity, so cold chamber die casting is more suitable for small-scale production.

Production efficiency

- Hot chamber die casting: Since the molten metal is heated directly inside the machine. The production cycle is short and suitable for high-volume production environments. Hot chamber die casting machines can produce continuously, thereby improving production efficiency.

- Cold chamber die casting: Each production cycle requires the addition of new molten metal from an external furnace. So the production speed is slow and suitable for small batch or customized production.

Hot chamber die casting offers higher production efficiency

- Shorter cycle times: Hot chamber die casting uses an integrated furnace and die-casting machine. The molten metal always contains within the machine. And the injection process is automated and continuous, resulting in significantly shorter cycle times.

- No external metal extraction required: Molten metal is poured directly into the mold via an immersed gooseneck. Eliminating the external furnace extraction and pouring steps required for cold chamber die casting, significantly reducing process time.

- High degree of automation: The integrated design reduces manual intervention, resulting in a more consistent production process and less waste.

Cold chamber die casting has low production efficiency

- Long cycle times: Liquid metal must be poured manually or automatically from an external furnace into the shot chamber. A process repeated for each cycle, extending the cycle time by approximately 30%-50%.

- Metal temperature control impacts efficiency: External material removal can cause the liquid metal to overheat, leading to defects. Such as cold shuts, increasing the defect rate and subsequent processing time.

Safety and maintenance

Hot chamber die casting offers greater safety

- Low operating temperature: Hot chamber die casting primarily processes low-melting-point metals (such as zinc and magnesium). With molten metal temperatures typically below 450°C, reducing the risk of high-temperature exposure.

- Minimal molten metal movement: The integrated design of the furnace and injection mechanism eliminates the need for external molten metal transfer. Reducing the risk of splashing, leakage, and contact.

- High degree of automation: Molten metal is directly injected into the mold from the internal furnace, minimizing manual intervention.

Cold chamber die casting presents greater safety challenges

- High-temperature operation: Molten metals (such as aluminum and copper) are processed, often reaching temperatures exceeding 600°C, increasing the risk of burns and heat radiation.

- External metal transfer: Molten metal must be transferred manually or robotically from a separate furnace to the injection chamber, generating dust and splashing during operation and posing a high risk of worker exposure.

- High-pressure environment: Higher injection pressures require stricter equipment sealing and protective measures.

Product quality

- Hot chamber die casting: Since the molten metal is directly injected into the mold. It can achieve high dimensional accuracy and surface finish. And it is suitable for manufacturing small parts with complex geometries.

- Cold chamber die casting: Although the production speed is slower, it can better control the metal flow and solidification process. Thereby reducing internal defects such as pores, etc., and is suitable for manufacturing thick-walled or complex parts.

Surface Quality and Porosity

- Hot Chamber Die Casting

Produces a smoother surface and lower porosity. Making it suitable for parts requiring sealing or a delicate appearance (such as electronic housings and USB ports). - Cold Chamber Die Casting

Due to the metal transfer process, exposure to air creates a higher risk of oxidation and impurities. Potentially leading to surface defects or increased porosity, requiring additional process control.

Dimensional Accuracy and Tolerance Control

- Hot Chamber Die Casting

Because the molten metal is directly injected, the temperature is stable, allowing for tighter dimensional tolerances (±0.05mm), making it suitable for precision parts. - Cold Chamber Die Casting

Metal temperature fluctuates significantly (external melting causes uneven cooling), potentially requiring post-processing to correct dimensions, increasing costs.

The choice of hot chamber die casting or cold chamber die casting depends on the specific application requirements, including material type, production scale, cost budget and product quality requirements. Each process has its own unique advantages and limitations, so in practical applications, it is necessary to make a reasonable choice based on the specific situation.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine and hot chamber die casting machine.They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts. When you have any demand, feel free to contact us.