The ejection space of a die casting machine refers to the area required for ejection system operation.

Typically, it is located in the ejection box or chamber,this space accommodates components like ejector plates and ejector pins.

Moreover, it allows the ejection plate to move during the ejection stroke to push the casting out.

When choosing the ejection stroke distance, consider factors such as mold thickness and die casting size.

And the material characteristics to ensure that the die casting process goes smoothly and gets a high-quality casting.

Definition and Role of Ejection Space

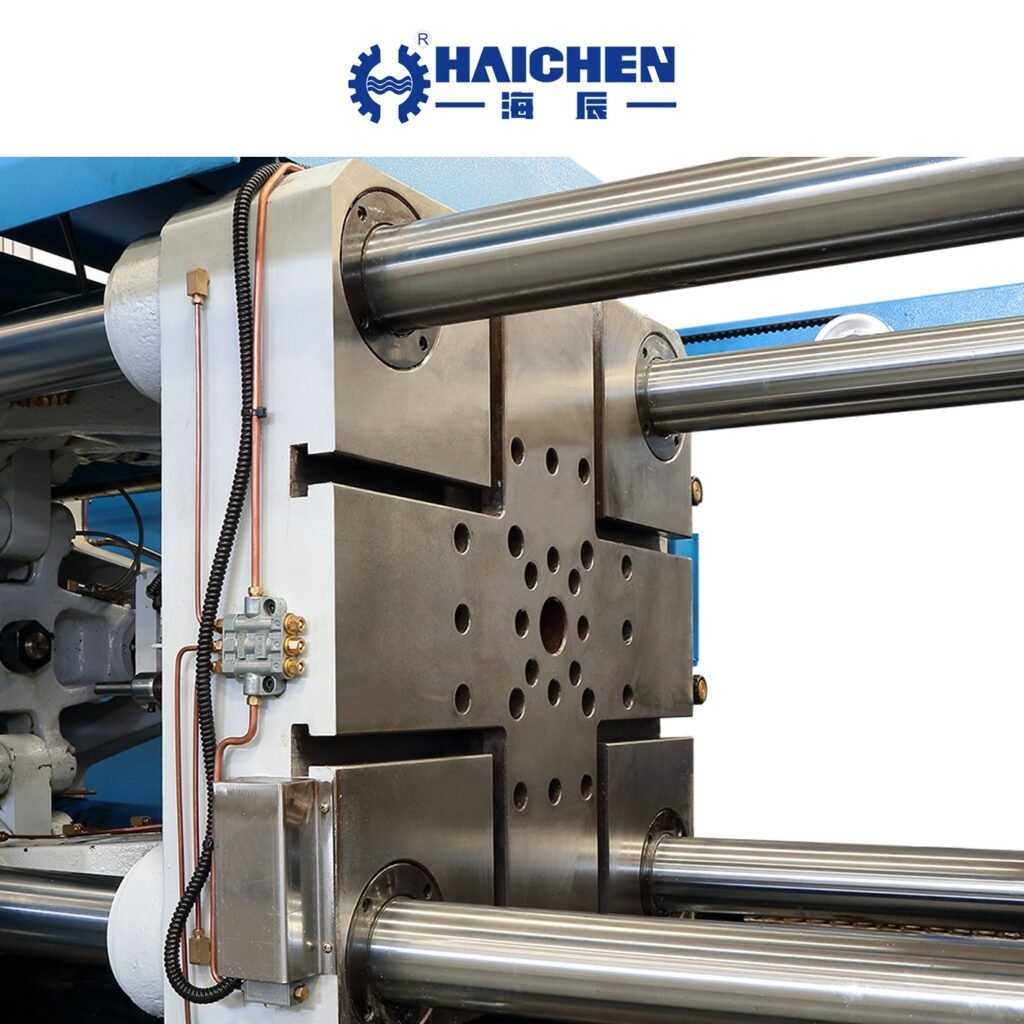

Firstly, the ejection space is a key area in die casting mold design, located in the ejector die half on the moving platen.

It features a hollow box-like structure containing ejection plates, ejector pins, guide rods, and return pins.

When the mold opens, the ejection system activates, and the ejection plate moves forward inside the box.

This action pushes ejector pins into the mold cavity to eject the casting.

Moreover, the space must be large enough for full plate movement, avoid interference, and distribute force evenly to prevent deformation.

The size of the ejection space depends on the ejector stroke and the mold size.

For instance, a hot chamber die casting machine has an ejection stroke of 70 mm,thus, the ejector plate requires at least 70 mm of moving space.

Moreover, the ejection box features a hollow structure,this allows the ejector plate to move relative to the ejection half-mold.

The impact of the size of the ejection space on die casting

- Affect mold life

- Casting quality

- Affects the thermal fatigue and thermal stress distribution of the mold

Affect mold life

Improper size of the ejection space may cause the ejector rod to jam and damage the ejector rod hole, which in turn will affect the mold life.

For example, insufficient dimensional accuracy or insufficient finish of the ejector rod hole can easily lead to the ejector rod jamming or aluminum input, causing damage to the ejector rod hole, and in severe cases, even leading to mold scrapping, affecting the mold life.

Casting quality

In addition, the size and position of the ejector rod diameter also have an impact on the casting quality.

Too large a diameter may lead to large forming marks on the surface of the casting, and too small a diameter will cause insufficient ejection strength and easy breakage of the ejector rod.

Therefore, the reasonable design of the ejection structure, such as the use of tapered pulling rod, can prevent the material flow from rushing directly into the cavity and improve the ejection effect.

Affects the thermal fatigue and thermal stress distribution of the mold

The size of the ejection space may also affect the thermal fatigue and thermal stress distribution of the mold.

For example, improper mold clearance settings can lead to mold locking or metal splashing, affecting casting quality and mold life.

In addition, the size of the ejection space may also affect the thermal balance and cooling effect of the mold, which in turn affects the mold life.

In conclusion, the size of the ejection space has a significant impact on the lifespan of the die casting mold and the quality of the casting.

Reasonable design of ejection structure and optimization of ejection space size and position can improve mold life and casting quality.

General principles and specifications of ejection system design

- Ejection stroke and position

- Structure and materials of ejection system

Ejection stroke and position

The ejection stroke is generally 5~10mm away from the mold, and large molds can be appropriately increased.

Additionally, the thimble surface should be 0.03~0.05mm higher than the rear die plane. Moreover, the distance from the thimble to the edge of the mold core should be about 5mm.

Furthermore, prevent the product from sliding near the inclined roof. Also, avoid the thimble contacting the front die. If necessary, add a split pusher block or a reset structure.

The exterior surface of the front mold is at least 0.4mm from the edge of the product. The splicing of the dome pin or barrel hole should be avoided.

Structure and materials of ejection system

Ejection systems come in various forms, including ejector pins, flat tops, cylinders, straight tops, inclined roofs, push plates, push blocks, etc.

The structural design of the ejection system takes into account the shape, structure and plastic properties of the product.

The ejector pin material is commonly used SKH51, SKD61, etc., and the hardness requirements are HRC52~58.

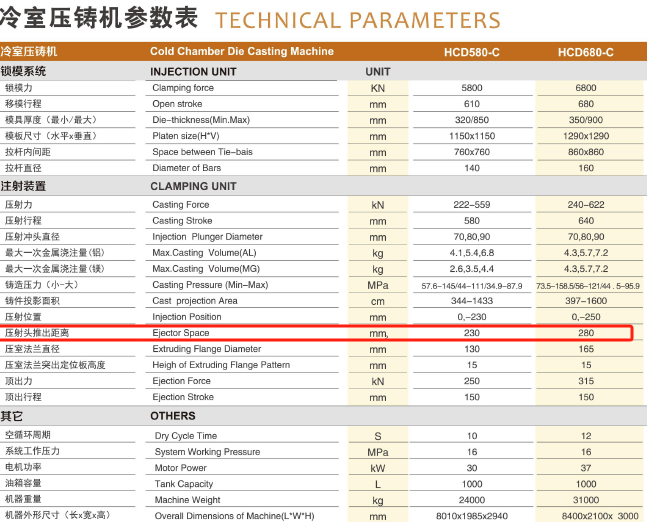

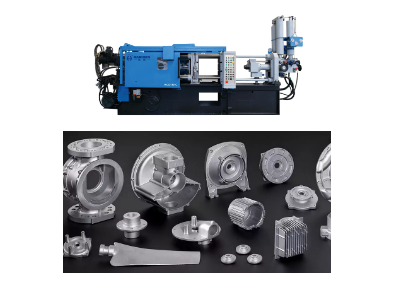

The ejector space of the Haichen die casting machine

- Mold design

- Optimize process conditions

- Mold space design

Haichen’s space adjustment in the mold design of the die-casting machine

The cushion block is between the moving mold base plate and the supporting plate, forming an activity space for the work of the push-out mechanism.

For small die-casting molds, the thickness of the spacer is also used to adjust the total thickness of the mold to meet the requirements of the minimum clamping distance of the die-casting machine.

Optimize process conditions

For more complex casting geometries, Haichen uses a complete model to analyze parameters such as wait time and punch speed to optimize process conditions.

Mold space design

Haichen die-casting machine adopts a larger mold space design, which can reduce the opportunity of flying materials, avoid material waste, and save production costs for customers.

If you need any help from Haichen in terms of die casting machine, please feel free to contact us.