Electrical Control Benefits include improving automation efficiency, ensuring the accuracy and stability of the production process, etc.

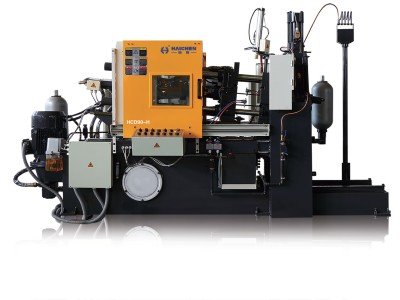

The die casting industry relies heavily on die casting machines which serve as essential equipment throughout a manufacturer’s production line. Each machine’s internal control system is equally important in terms of maintaining its operational effectiveness and accuracy.

Prompt industry advancement can be positively attributed to the development of advanced manufacturing technologies with contemporary electrical drive systems which give the operator more authority over the machine.

Electrical control systems are the backbone of modern die casting machines, providing the system with numerous advantages, including saftey, productivity boost, and profit increase. In this article, we will explore the advantages of electrical control.

Enhanced Automation and Efficiency

One of the major benefits of die casting integration is the degree of automation achieved throughout the entire process. The combination of electrical and computer control has resulted in higher production rates and improved operational reliability.

As a result of the advantages of electrical control, injection speed, pressure, and temperature can be maintained within predetermined limits as functions of time robotically.

Precise Control

For every necessity regarding control of measuring elements used within injection die casting, electrical control covers an adequate range considerable temperature objectives and requirements, such as time, cooling, and injection pressure.

The optional control of injection speed in automotive part injection metal molding ensures a perfect injection of the molten metal into the mold. The smooth flow of molten metal guarantees that even the most intricate geometries are defect free.

Consistent flow of metal, being controlled with precision, guarantees no occurrence of porosity and consistent thickness of walls to be with utmost uniformity.

Dependability and Constancy

Dependable electrical control systems are being manufactured these days. These systems are proven to be stable throughout difficult industrial conditions. The odds of system breakdown are minimum and guarantee uninterrupted processes.

Advanced systems are said to minimize downtime as these systems posses redundant features accompanied by fail safes.

Due to the harsh conditions surrounding factories, these systems are also protected from common temperature changes and power supply fluctuations. The aid in sustaining stable operation also answers the need for consistent quality system production and rink the occurrence of production halts which can be expensive.

In systems such as automotive and aerospace the importance of reliable systems during halts is said to be financially and operationally demanding.

Energy Saving

Critically examining the flow of energy, consumption levels, and production processes helps achieve energy-efficient production Meanwhile, electrical control systems facilitate energy optimization, significantly reducing energy consumption.

Based on real-time production demand, they can modify power demand for different processes, meaning energy is only consumed when actually required.

During periods of low production activity, the control system can automatically switch the machine to a low-power mode. This lowers operational costs and enhances eco-friendliness by reducing the carbon footprint associated with manufacturing processes.

Moreover, advanced control systems can optimize the heating. And cooling cycles of the die casting machine to further improve energy performance.

There is opportunity to achieve significant cost savings for manufacturers while ensuring the high production standards set by the industry by integrating these energy-saving features.

Safety

Control systems can include a variety of features like an emergency stop button. And access control as well as overload protection shield operator and equipment safety.

In the case abnormal conditions are detected, modern control systems can shut down the machine. This is made possible with the use of sensors that monitor operational parameters.

There is potential for enhanced personnel and equipment safety. And the reduction of hazard risks by electrical control systems through the addition of these elaborate safety features.

Data Capture and Evaluation

The advantages of advanced electrical control for die casting machines incorporate data recording for production. Which enables the process to be analyzed. This helps the manufacturers to make adequate informed decisions.

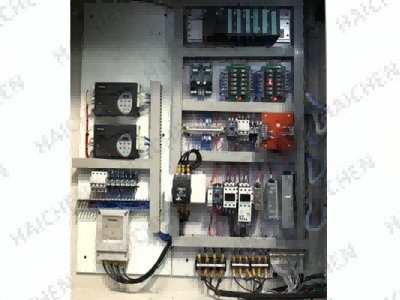

Electrical Control Systems in Haichen Die Casting Machines

Haichen integrates sophisticated electrical control systems into its machines. These systems are intended to provide operational accuracy on all tasks performed.

The controls in the machines allows fine tuning of ranges such as injection speed. And pressure for the desired outcome, thus every casting will be within defined tolerance limits.

That would be important for providing components parts that are to be very accurately finished to high standards with extremelyhighquality surfaces. And having very close standards mechanical features.

Additionally with regard to the controls. All the enabling functions like interfaces are flexible to allow ease to the operators for smooth management of the casting processes.

Reliance on advanced electrical controls to the machines ensures that they are very stable in production . While maintaining the quality of products supplied to the intended market.

As noted above, the entire operational advanced control system to the h die-casting machine is computerized thus intelligent. This spreads out the design work whilst improving the efficiency and convenience of their operation.

This approach without forgetting applies advanced electrical control by focusing on stability. And reliabilityof the machine weakening failure focus creating continous smoth steady dependable production.

In short, the electrical control advantages of die-casting machines are numerous and far-reaching. They not only improve production efficiency and product quality, but also enhance the safety and ease of operation.