Electronics Die Casting products are mainly zinc alloy products.Zinc die casting is used in the electronics industry mainly for its ability to manufacture complex shapes and precision-sized parts, as well as its cost-effectiveness.

These kind alloys are widely using in the manufacture of electronic products, such as computers and consumer electronic devices, because of their low melting point, good flowability, high productivity and low tooling costs.

Zinc die castings offer many advantages, including the ability to produce complex geometries, high dimensional accuracy, good surface finish, and no additional machining.

These properties make zinc alloys ideal for electronic device housings, connectors and other functional components.

In addition, zinc alloys are castable, allowing for thin-walled designs that reduce product weight and improve thermal conductivity.

Zinc alloy die castings usually require surface treatment to improve their corrosion resistance and decorative properties.

Electroplating is a common surface treatment that provides a high-quality protective and decorative surface for zinc alloy die castings.

Zinc die casting is widely used in the electronics industry and offers significant advantages, but there are also technical challenges that need to be addressed to improve product quality and reliability.

Is zinc good for die casting?

Zinc is a very suitable material for die casting.Zinc and its alloys exhibit many advantages in the die casting process.

Zinc has a low melting point (approx. 419°C), which makes it easy to work with during the die casting process.

At the same time, it maintains high strength and good surface quality.

In addition, zinc’s good flowability allows it to easily fill complex moulds, thus producing products with high precision and meticulous detail.

Zinc alloys are commonly used in a wide variety of industrial applications, including automotive, Electronics Die Casting products and home appliances.

For these applications, zinc alloys are favoured for their excellent mechanical properties, corrosion resistance and thermal conductivity.

Zamak alloys, in particular, are the leading choice for die cast zinc alloys in North America due to their excellent castability and dimensional stability.

Zinc alloys also have good corrosion resistance and long mould life.

This makes it highly economical for die casting production.

In addition, zinc alloys are relatively inexpensive to produce and can be recycled, further reducing production costs and minimising environmental impact.

Zinc is a very suitable material for die casting, with cost-effective, machinability and dimensional stability for a wide range of industries.

What is zinc used for in electronics?

Zinc has a variety of uses in the electronics industry, mainly in the following areas:

- Manufacture of die-cast electronic components

- Applications in Batteries

- Semiconductor materials

- Anti-corrosion coating

- Solar cells and other renewable energy equipment

- Flexible electronic devices

Manufacture of die-cast electronic components

Zinc is used in die casting for the manufacture of a variety of Electronics Die Casting products, including connectors, switches, contacts, and so on.

These components require precise dimensions and good electrical conductivity, and these properties of zinc make it ideal.

Applications in Batteries

Zinc is an important component of many batteries, especially alkaline and zinc-air batteries.

Zinc is usually used as an anode material in these batteries, providing current through an oxidation reaction.

Semiconductor materials

Zinc oxide (ZnO) is an important semiconductor material widely used in electronic and optoelectronic devices.

Examples include ultraviolet light-emitting diodes, field emission devices, transparent conductive materials, piezoelectric transducers, and so on.

Anti-corrosion coating

Zinc is commonly used in electroplating or hot dip galvanising of metal surfaces to prevent corrosion.

This application not only protects the metal surface, but also improves the durability and reliability of the equipment.

Solar cells and other renewable energy equipment

Zinc is also used in the manufacture of solar cells and other renewable energy devices.

For example, zinc oxides are being investigated for transparent electronic devices and solar cells due to their excellent photovoltaic properties.

Flexible electronic devices

With the development of technology, zinc-based batteries are gradually being used in flexible electronic devices.

These devices have attracted attention for their high energy density, low cost and environmental friendly properties.

Zinc is used in a wide range of applications in the electronics industry, from die-cast electronics parts to semiconductor materials to anti-corrosion coatings and flexible electronic devices, where its unique physical and chemical properties make it an indispensable material.

Haichen zinc alloy electronic products die-casting machine

- Introduction

- Haichen zinc alloy die casting machine application field

- The future development of zinc alloy die casting machine for electronic and electrical appliances

Introduction

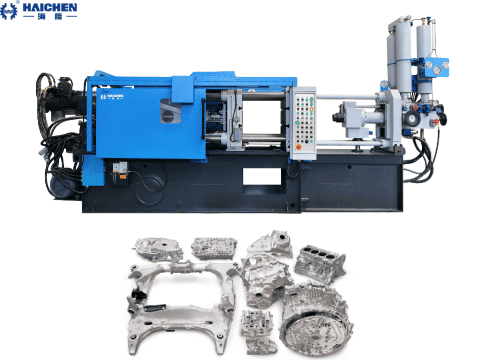

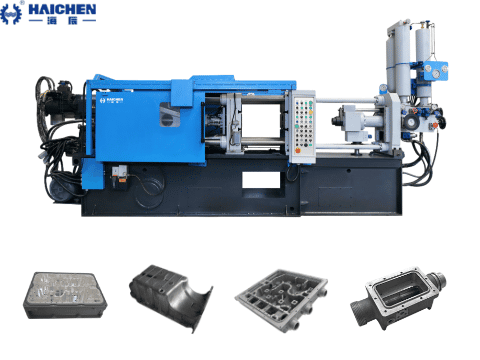

With more than 20 years of production experience and technology accumulation, Haichen has strong competitiveness in the field of zinc alloy die casting machines.

Our product design focuses on environmental protection, energy saving, automation and intelligence.

We also provide online engineer support to ensure that customers can quickly solve problems in use.

Haichen zinc alloy die casting machine application field

Haichen’s zinc alloy die casting machines are widely used in electronic and electrical appliances, auto parts, daily hardware, household appliances and other industries.

Zinc alloy die casting has good fluidity, low melting point, easy processing, etc. It is very suitable for manufacturing precision parts and thin-walled castings.

In addition, Haichen’s zinc alloy die castings are also used to produce medals, trophies and other souvenirs.

The future development of zinc alloy die casting machine for electronic and electrical appliances

Haichen’s zinc alloy die casting machine in the field of precision casting has an important position, and with the machinery manufacturing technology and automation technology progress, its performance and application range is constantly upgraded.

In the future, zinc alloy die casting machine will pay more attention to intelligent and modular design, in order to adapt to the needs of different industries.

Choose us to solve more problems for you, welcome to contact us at any time.