Energy saving hydraulic valve solution for die-casting machines includes efficient hydraulic system design, applicate servo control technology, optimize and innovate hydraulic valves etc.

Traditional fixed-speed oil pumps maintain high pressure during idle periods, resulting in 36%-68% of energy wasted in the form of throttling. Servo energy saving variable displacement pumps or servo motor-driven pumps can adjust flow and pressure in real time based on actual demand, saving energy by up to 45%-85%.

In order to achieve energy-saving solutions for hydraulic valves of die-casting machines, we can explore and optimize from the following aspects:

- Efficient hydraulic system design

- Application of servo control technology

- Optimiztion and innovation of hydraulic valves

- Real-time monitoring and adjustment of hydraulic valves

- Modularization and Customization of Hydraulic Valves

- Maintenance and testing of hydraulic systems

- Selection of energy-saving materials

- Application of vacuum die-casting technology

Efficient hydraulic system design

The use of energy-efficient motors and pumps can significantly improve the performance of hydraulic systems and reduce noise.

In addition, by redesigning the hydraulic circuit, higher operating speeds can achieve while using smaller pumps, thereby saving electricity. This design not only improves the efficiency of the system, but also reduces energy consumption.

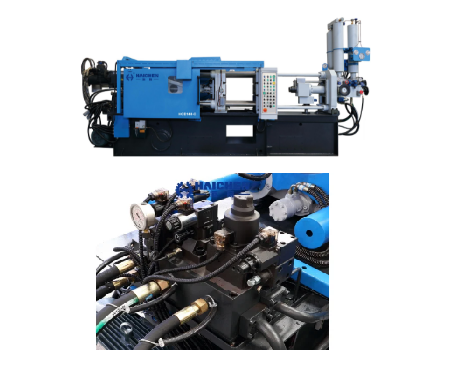

Haichen high-performance die-casting machines, precision-engineered hydraulic valves are the critical components that translates power into controlled motion. These robust valves precisely manage the flow and pressure of hydraulic fluid to orchestrate every phase of the casting cycle. From the high-speed injection of molten metal to the exacting clamp force and smooth ejection of the final part, Haichen’s valves ensure repeatable, reliable, and efficient operation.

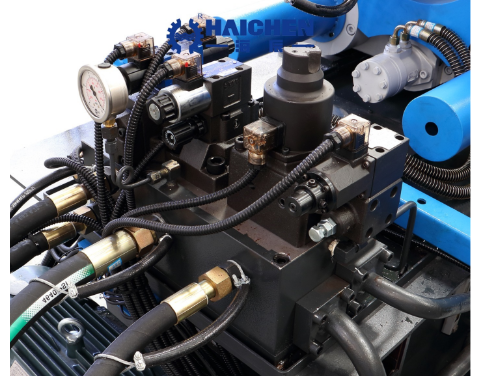

Piping Layout of die casting hydraulic valve solution

Use short, appropriately diameter piping to minimize pressure drop and leakage.

Valve Selection of die casting hydraulic valve solution

Prefer proportional or servo valves to avoid energy waste caused by check valves or constant flow valves.

System Leakage Control

Use high-precision seals and perform regular maintenance to keep the leakage rate below 0.5%.

Modular Design of die casting hydraulic valve solution

Utilize an integrated valve block and cylinder module for easy assembly, commissioning, and future upgrades.

Energy Consumption Monitoring

Power meters and pressure gauges are placed at key system nodes to record energy consumption data in real time, providing a basis for subsequent optimization.

Application of servo control technology

- Load Sensing

- Variable Displacement Pump-Servo Valve Synergy

- Energy Recovery and Storage

The application of servo valve control technology in die casting machines can achieve more flexible injection performance settings.

While also featuring energy saving, cleanliness, high cycle times, and impact-free injection. For example, by using high-performance servo motors and optimized hydraulic circuit design, it can reduce energy loss in the hydraulic system. Moreover, extend the service life of the equipment.

Load Sensing of die casting hydraulic valve solution

- Pressure sensors measure the required oil flow in real time, controlling pump displacement and valve opening to maintain system pressure at the minimum required value.

- Experiments have shown that this strategy can reduce overall energy consumption by approximately 45% and improve production efficiency by approximately 5%.

Variable Displacement Pump-Servo Valve Synergy

- A servo motor-driven variable displacement pump rapidly adjusts displacement based on control commands; a proportional valve fine-tunes flow, achieving high-speed response and high energy efficiency.

- Compared to traditional fixed-displacement pump-constant-flow valve systems, energy consumption is reduced by 50-60%.

Haichen die casting machine us the precise hydraulic valve control is fundamental to achieving the machine’s renowned stability, rapid cycle times, and production of high-integrity castings with exceptional consistency.

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Energy Recovery and Storage of Die casting hydraulic valve solution

- During the piston’s return stroke or deceleration phase, hydraulic energy is stored in an accumulator and released during subsequent acceleration, reducing the pump’s instantaneous power demand.

- This technology has demonstrated significant energy savings in actual retrofitted models.

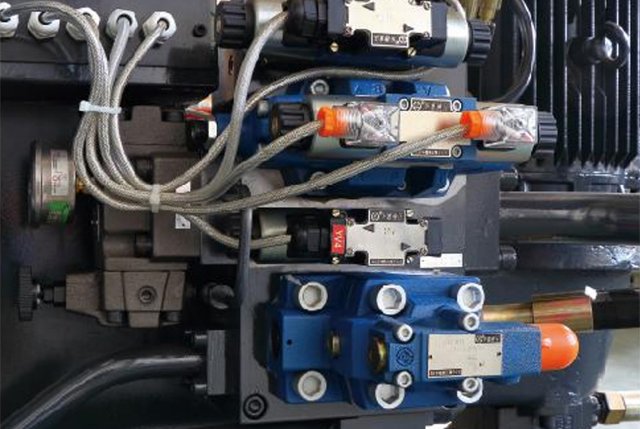

Optimiztion and innovation of hydraulic valves

- Using advanced hydraulic valve designs, such as Domin’s servo valves, can reduce maintenance costs and increase equipment uptime.

- This design avoids the leakage problems common in traditional two-stage valves.

- And achieves responsive control of the hydraulic system through advanced algorithms.

- In addition, by improving the materials and structures of hydraulic valves, such as using aluminum castings or forged cast iron, the system’s ability to withstand high temperatures.

- And it can improve high pressures, and further improve energy savings.

Load Sensing and Pressure Matching

- Pressure sensors are used to adjust pump displacement in real time, ensuring that the oil supply pressure always matches actual demand and reducing overflow losses in constant-pressure pumps.

- Reference: Variable-displacement pump-servo system achieves over 45% energy consumption reduction after die-casting machine retrofit.

Coordinated Multi-Valve Control

- Using the opening of a 5-valve programmable valve as a multi-dimensional control variable, a two- or three-layer control structure is employed: the task layer determines the valve combination, and the valve layer performs adaptive robust control.

- Reference: Coordinated control scheme achieves high accuracy and significant energy savings in experiments.

Energy Regeneration and Energy Storage Scheduling

- Storing oil kinetic energy in an accumulator during braking or reversing, and then releasing it during acceleration, reduces peak pump power demand.

- Reference: Connecting an energy storage device after the proportional valve reduces overall system energy consumption by 50-60%.

Real-time monitoring and adjustment of hydraulic valves

- Real-time monitoring of the pressure, flow and speed of the hydraulic system can ensure that the system operates in the best condition.

- For example, by integrating sensors and control systems, it can precisely adjust the hydraulic system to reduce unnecessary energy consumption.

Modularization and Customization of Hydraulic Valves

- Hydraulic valves can modularly design and customize according to customer needs. Which to meet the requirements of ordinary and special working conditions.

- This flexibility allows the hydraulic system to be optimized according to different application scenarios, thereby achieving higher energy efficiency.

Maintenance and testing of hydraulic systems

- Regular maintenance and testing of hydraulic systems are important measures to ensure their efficient operation.

- For example, a comprehensive hydraulic pipeline test before operation can ensure the normal operation of the system and avoid energy waste caused by failures.

Selection of energy-saving materials

- Using lightweight materials (such as aluminum) to manufacture hydraulic valve bodies.

- It can not only reduce system weight, but also reduce energy consumption.

- In addition, selecting alloy materials with high wear resistance and vibration resistance (such as 390 aluminum alloy) can extend the service life of hydraulic valves and reduce maintenance frequency.

Application of vacuum die-casting technology

In some cases, vacuum die-casting technology can improve product quality and efficiency by optimizing the exhaust process. For example, the use of mechanical vacuum valves or high vacuum cutting valves can reduce the possibility of aluminum liquid entering the equipment and improve overall production efficiency.

Through the above measures, we can significantly improve the energy efficiency of the hydraulic system of the die casting machine. And reduce energy consumption, extend the service life of the equipment. These improvements not only help to reduce production costs, but also contribute to environmental protection and sustainable development.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.