Exploring the differences in die casting involves comparing various aspects such as the types of metals used, the specific processes like hot chamber versus cold chamber, and the resulting characteristics of the final products in terms of strength, precision, and cost – effectiveness.

Die casting is a versatile and highly efficient manufacturing process used to produce complex metal parts with precision and consistency.

It involves injecting molten metal into a reusable mold (or die) under high pressure, allowing the metal to cool and solidify before being ejected.

While the basic principles of die casting remain consistent, there are several key differences that can impact the final product, production efficiency, and cost.

Hot Chamber vs. Cold Chamber Die Casting

Die casting can be broadly categorized into two types: hot chamber and cold chamber processes. The primary difference lies in how the molten metal is introduced into the mold.

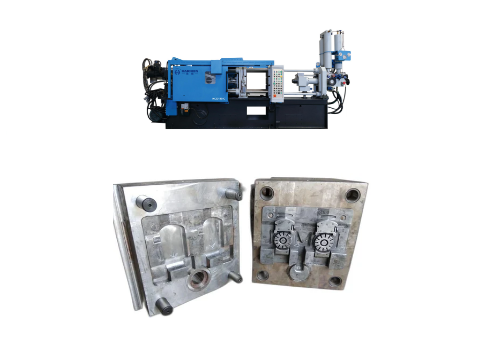

Hot Chamber Die Casting

In this process, the metal is melted in a chamber that is an integral part of the machine. The molten metal is then directly injected into the mold using a plunger. This method is ideal for metals with low melting points, such as zinc and magnesium. It offers faster cycle times and reduced waste, making it highly efficient for high-volume production.

HAICHEN’s Innovations in Hot Chamber Die Casting:

HAICHEN’s HCD-H series hot chamber die casting machines are specifically optimized for zinc and magnesium alloys. Their unique closed-loop control system precisely regulates the injection process and metal temperature, ensuring process stability. With the injection mechanism immersed in the molten metal, HAICHEN hot chamber machines achieve extremely fast cycle times (typically up to 800 shots per hour), making them ideal for mass production of small to medium-sized parts such as gears, housings, and connectors.

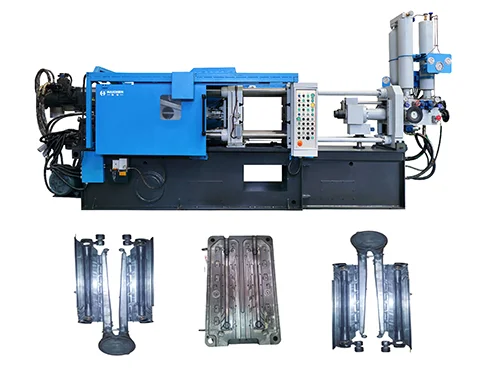

Cold Chamber Die Casting

Here, the molten metal is poured into a separate chamber before being injected into the mold. This method is used for metals with higher melting points, such as aluminum and copper alloys. While it requires more manual intervention, it allows for greater control over the metal temperature and is suitable for larger and more complex parts.

Advantages of HAICHEN’s Cold Chamber Technology:

HAICHEN’s HCD-C series cold chamber die casting machines are designed specifically for aluminum and copper alloys, equipped with large injection cylinders and high-pressure systems capable of producing larger, more complex parts. Our real-time monitoring system ensures metal temperature remains optimal, while automatic pouring options reduce manual intervention, improving production consistency and efficiency.

Material Selection

The choice of material significantly impacts the die casting process and the final product. Common materials include aluminum, zinc, magnesium, and copper alloys, each with unique properties and applications.

- Aluminum: Known for its lightweight, high strength, and excellent corrosion resistance, aluminum is widely used in automotive, aerospace, and consumer electronics.

- Zinc: With its low melting point and high ductility, zinc is ideal for intricate parts and thin-walled components. It is commonly used in small hardware and decorative applications.

- Magnesium: Magnesium is the lightest structural metal, offering excellent strength-to-weight ratio and ease of machining. It is increasingly used in automotive and aerospace applications for weight reduction.

- Copper Alloys (Brass, Bronze): These materials offer high strength, wear resistance. And thermal conductivity, making them suitable for industrial components and plumbing fixtures.

Mold Design and Complexity

The design of the die casting mold plays a crucial role in determining the quality and functionality of the final product. In particular, complex parts with intricate geometries require highly engineered molds with multiple cavities, slides, and cores. Advanced mold design techniques, such as computer-aided design (CAD) and simulation, help optimize mold performance and reduce defects like porosity and shrinkage.

The Role of Advanced Die Casting Machines

HAICHEN, a leading die casting machine manufacturer, plays a pivotal role in enhancing the efficiency and precision of the die casting process. Above all, Our machines are designed to offer high accuracy, consistent performance, and ease of operation. Key features include:

- Precision Control: Advanced control systems ensure precise regulation of injection speed, pressure, and temperature, reducing defects and improving part quality.

- High-Speed Production: HAICHEN machines are optimized for fast cycle times, making them ideal for high-volume production runs.

- Energy Efficiency: Modern machines from HAICHEN incorporate energy-saving technologies, reducing operational costs and environmental impact.

- Automation and Integration: HAICHEN machines often come with automated features, such as robotic handling and integrated quality control systems, which enhance productivity and reduce labor costs.

Applications Across Industries

Die casting is used across a wide range of industries due to its ability to produce complex, high-quality parts efficiently. Some common applications include:

- Automotive: Engine components, transmission housings, and structural parts.

- Aerospace: Lightweight structural components, engine parts, and avionics housings.

- Consumer Electronics: Enclosures for smartphones, laptops, and other electronic devices.

- Medical Devices: Precision components for surgical instruments and diagnostic equipment.

- Construction: Hardware, fittings, and decorative elements.

Understanding the differences in die casting processes, materials, and mold designs is essential for optimizing production and achieving high-quality results. Whether for automotive parts, consumer electronics, or medical devices, remains a versatile and reliable manufacturing process, delivering complex, high-quality components with remarkable efficiency.