Extend die casting hydraulic valve life includes optimize hydraulic maintain and care, improve hydraulic system design and other main factors.

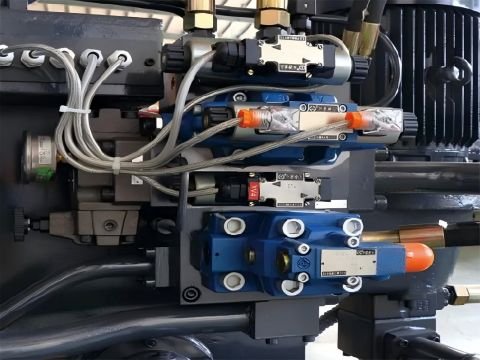

In a hydraulic system, the hydraulic valve is one of the core components. And its performance directly affects the efficiency and life of the system.

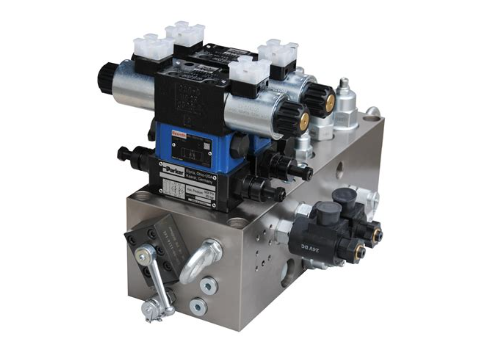

Choosing a suitable hydraulic valve requires considering factors such as its model, structure type, and working pressure. For example, according to the model analysis of the hydraulic valve, different types of hydraulic valves (such as two-position four-way reversing valves, regulating relief valves, etc.) are suitable for different application scenarios.

- Optimize the maintenance and care of the hydraulic system

- Improve hydraulic system design

- Improve hydraulic oil quality and filtration accuracy

- Using advanced materials and technologies

- Regular inspection and preventive maintenance

- Reduce the impact of the external environment on the valve

Therefore, the correct selection of hydraulic valves can significantly improve the stability and life of the system.

Optimize the maintenance and care of the hydraulic system

Hydraulic system maintenance is an important means to extend the life of hydraulic valves.

Regularly check whether the valves in the hydraulic system are worn or leaking. Such as checking whether the sealing performance of the check valve, relief valve and pressure reducing valve is good.

In addition, maintaining the cleanliness of the hydraulic oil is also key. Because hydraulic oil contamination will cause increased wear inside the valve, thereby shortening the service life.

- Daily maintenance and care

- Weekly maintenance and care

- Monthly maintenance and care

- Every 300 hours maintenance and care

- Every 500 hours (new machine) maintenance and care

- Yearly maintenance and care

Daily maintenance and care

Check oil temperature, oil pressure, and leaks; record any abnormalities

Weekly maintenance and care

Visually inspect hoses and valve body; clean any dust.

Monthly maintenance and care

Replace filters (if using disposable elements) and inspect seals for wear.

Every 300 hours maintenance and care

Verify valve body alignment and record torque changes.

Every 500 hours (new machine) maintenance and care

Or 2000 hours (conventional machine) complete oil change and circuit flushing.

Yearly maintenance and care

Perform complete preventive maintenance (including hose replacement, lubrication, and valve body disassembly).

Improve hydraulic system design

The service life of hydraulic valves can be extended by optimizing the design of hydraulic systems. For example, the use of closed-loop regenerative injection systems and auxiliary servo pumps can balance the hydraulic forces. Thereby extending the life of speed control valves.

In addition, reasonable setting of vacuum system parameters (such as vacuum time, stabilization time, etc.) can also effectively reduce valve wear caused by high temperature or pressure fluctuations.

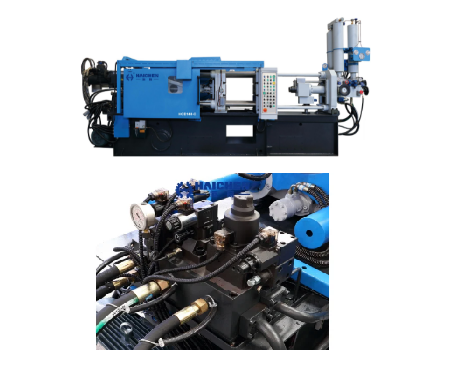

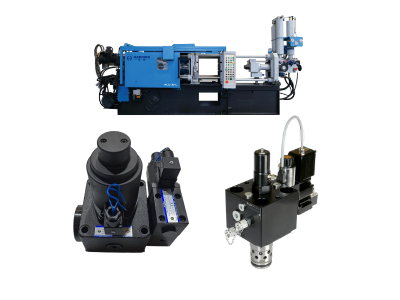

In Haichen die-casting machines, precision-engineered hydraulic valves are the critical components that translate power into controlled motion. These hydraulic system valves precisely manage the flow and pressure of hydraulic fluid to orchestrate every phase of the casting cycle.

From the high-speed injection of molten metal to the exacting clamp force and smooth ejection of the final part, Haichen’s valves ensure repeatable, reliable, and efficient operation. This precise hydraulic control is fundamental to achieving the machine’s renowned stability, rapid cycle times, and production of high-integrity castings with exceptional consistency.

High pressure differential and shock

Rapid pressure drops or increases can cause valve core shock, erosion, and seat wear.

Cavitation

Steam bubbles form in the high pressure drop area, and their subsequent collapse causes impact erosion on the valve body.

Seal wear

Particles in the operating oil or oil temperature fluctuations can cause seal surface wear and leakage.

Elevated oil temperature

Localized overheating accelerates material softening and seal aging.

Improve hydraulic oil quality and filtration accuracy

The quality of hydraulic oil directly affects the operating efficiency of the hydraulic system and the life of the valve.

Using high-quality hydraulic oil and equipping it with an efficient filter can effectively reduce the erosion of impurities on the valve. Studies have shown that filtration accuracy is closely related to the service life of the hydraulic valve.

System Seal Inspection

Regularly inspect seals on the oil tank, piping, and valve bodies to prevent the ingress of external contaminants.

Temperature Control

Maintain the oil temperature within the recommended range (typically 40°C–70°C) to prevent high temperatures from accelerating oil oxidation and viscosity loss.

Cleanliness Standards

When changing oil or filters, use clean tools and containers to prevent secondary contamination.

Recordsets and Traceability

Maintain a log of oil changes, filter changes, and oil sample analysis to facilitate trend analysis and preventive maintenance.

Using advanced materials and technologies

Using high-quality materials to manufacture hydraulic valves. Such as stainless steel or high-temperature resistant alloy materials, can improve the corrosion resistance and durability of the valves.

In addition, combining modern technologies (such as magnetic filtration devices) to further improve sealing performance can also extend the service life of hydraulic valves.

Regular inspection and preventive maintenance

Regular inspection and maintenance of the hydraulic system is an important measure to extend the life of the hydraulic valve. For example, check the roller of the valve for wear and internal leakage every two years.

At the same time, ensure that all valves are in good condition before operation. And adjust the pressure and speed in time during operation to avoid excessive load.

Reduce the impact of the external environment on the valve

High temperature, high pressure or severely polluted environment will accelerate the aging of hydraulic valves.

Therefore, when designing and installing hydraulic systems, try to avoid exposing valves to harsh environments and take appropriate protective measures.

Through the above methods, the service life of the hydraulic valve of the die-casting machine can be effectively extended and the overall performance and reliability of the system can be improved.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.