Basic technological process of die casting mold: First, we pour molten metal into the mold cavity at low or high speed; the mold has a movable cavity surface.

We forge the metal under pressure as it cools, which eliminates shrinkage and porosity defects in the blank.

But also make the internal structure of the blank reach the broken grains in the forged state.

Die casting mould installation is a complex and highly technical job, which needs to be operated in strict accordance with specifications.

To ensure the normal operation of the mold and the quality of the product.

Preparation before the installation of the die casting mould

- Die casting mould inspection

- Equipment inspection

- Site Preparation

- Mould installation steps

- Fixing the mold

- Adjust the clamping clearance

- Install the cooling system

- Debugging the mould

Die casting mould inspection

First of all, check whether the mold is intact, whether the parts are complete, and whether the surface is clean and dust-free.

Secondly, confirm that the mold matches the model of the die-casting machine to avoid installation failure caused by the mismatch of mold size or structure.

Finally, check the accuracy of the mold, including whether the dimensions of key components.

Such as cavities, cores, guide pillars, and guide bushings meet the requirements.

Equipment inspection

Before installing the mold, it is necessary to check whether the lifting equipment, hook bolts, and screw holes of the die-casting machine are in good condition to ensure that the equipment can safely carry the mold.

It is also necessary to confirm that the hydraulic system, cooling water channel and lubrication system of the die casting machine are working properly.

Site Preparation

Clean the mounting surface of the die casting machine to ensure that it is flat and free of debris.

Also, prepare the necessary tools and auxiliary equipment, such as screws, gaskets, lubricants, etc.

Mould installation steps

Hoisting the mould Use lifting equipment to lift the mold onto the die-casting machine, taking care to avoid damage to the mold.

Fit the mold to the moving mold holder, ensuring alignment between the mold centerline and injection chamber flange face.

Fixing the mold

Fix the top of the mold on the guide rail, and increase the fixing strength through screws.

Ensure that the slider stroke of the mold is flexible and the positioning is accurate.

Adjust the clamping clearance

Adjust the clamping clearance of the mold to make it meet the design requirements.

Use the clamping trial method to check whether the mold is completely closed to ensure that there is no gap.

Install the cooling system

Make sure the cooling water is clear, connect the cooling water pipes and check the tightness.

For special molds, such as those with cooling channels, thermally conductive components need to be installed to reduce cooling costs.

Debugging the mould

Start the die-casting machine for no-load debugging and check whether the mold is running smoothly.

Adjust the slider stroke and the length of the push rod to ensure that the mold action is coordinated.

Precautions for mould installation

- Regular Inspection and Maintenance

- Mould preheating and heat preservation

- Parameter Adjustment & Optimization

- Operational Training & Safety Specifications

Regular Inspection and Maintenance

Regularly check the integrity of lifting equipment, bolts and bolts to ensure safety when lifting heavily.

It is best to check the cleanliness and lubrication of the mold, and clean the burrs or impurities on the surface of the mold in time.

Mould preheating and heat preservation

Preheat the mould before production to ensure that the mold temperature meets the process requirements.

If necessary, use a holding furnace or other heating equipment to preheat the mold.

Parameter Adjustment & Optimization

Adjust injection parameters, cooling time, and lubrication frequency according to production needs.

For molds with complex structures , special attention should be paid to the coordination of their movements.

Operational Training & Safety Specifications

Die casting operators need to be professionally trained and familiar with operating procedures.

The most important thing is to follow safe operating procedures to avoid mold damage or personal injury due to improper handling.

Common problems and solutions for mold installation

- Loose clamping

- Cooling system leakage

- Abnormal slider action

- Mold surface scratches

Loose clamping:Check whether the clamping gap is too large, and readjust the clamping parameters if necessary.

Cooling system leakage:Check the cooling water pipe connection for leakage and replace the damaged parts in time.

Abnormal slider action:Check whether the slider stroke is flexible, adjust the slider positioning or replace the damaged parts if necessary.

Mold surface scratches:Use gasket protection during mold handling to avoid scratches caused by direct contact.

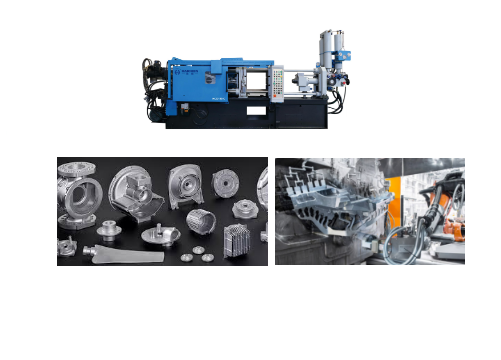

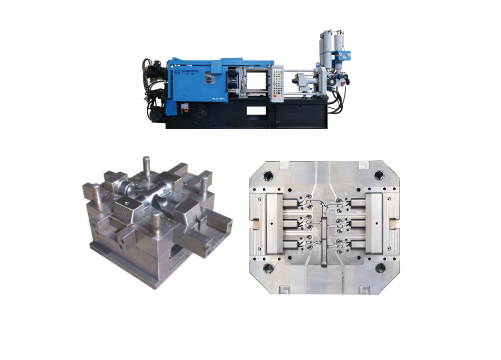

Haichen‘s die casting molds

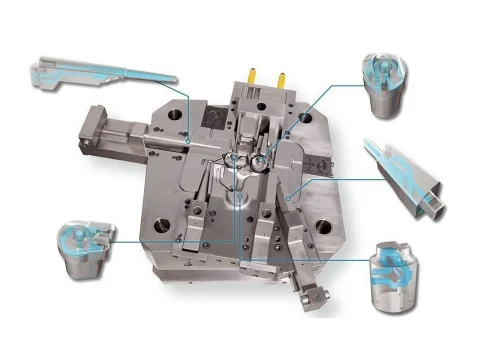

Die Casting Mold Definition Haichen’s die casting mold consists of two parts, separated according to the draft slope of the product.

Molten metal is injected from the stationary end and cooled and solidified into a die casting.

The die casting stays at the moving end, and the moving end ejects the die casting through the ejector pin, and sprays lubricant on the mold after taking it out.

Secondly, in the early stage of mold design, Haichen will confirm the mold flow analysis and product analysis report.

And start with a simple mold design until the product drawings are approved by the customer.

Analyze the shape, structure and size of die casting materials, product parts from the perspective of die casting processing performance accuracy.

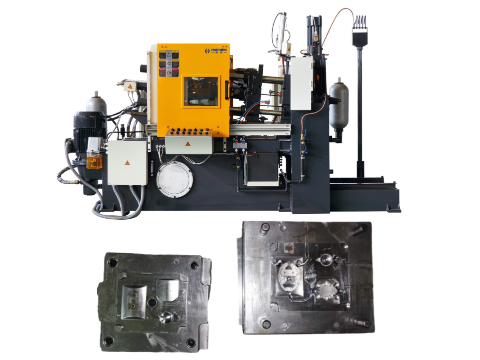

Components of a Haichen die casting mould

- Mold Cavity

- Mold Core

- Sprue

- Runner

- Gate

- Ejector System

- Cooling System

- Venting System

Mold Cavity

The cavity is the hollow space within the mold, essentially the negative impression of the final part’s exterior.

When the mold is closed, molten metal is injected under high pressure into this cavity space, and the metal takes on the shape of the cavity as it solidifies.

In a typical die, the cavity is created by a hardened steel insert mounted in one half of the mold with proper draft angles (slight tapers) and smooth surfaces to allow the solidified part to eject easily without damage.

Mold Core

The core is the cavity’s counterpart; it forms the casting’s interior features, along with all required recesses and holes.

In die casting molds, we often mount the core on the moving half to extract solidified metal during mold opening.

Cores can be fixed or movable; fixed cores remain in position to form features such as through-holes.

While a movable core (or slide) can retract before the mold opens to release undercut features.

Sprue (Molten Metal Inlet)

The sprue is the primary channel through which molten metal enters the mold.

In a die casting mold, the sprue is often a tapered vertical passage that connects the machine’s injection system to the runner inside the die.

A well-designed sprue minimizes turbulence and air entrapment during metal injection.

In a hot-chamber die casting machine, the sprue is the opening that feeds molten metal out of the gooseneck into the die; in a cold-chamber machine, it takes in metal from the shot sleeve.

Once the mold fills and the casting solidifies, the metal in the sprue solidifies as well, typically attaching to the cast part and often forming a cylindrical biscuit or leftover that workers trim away afterward.

Runner

The runner is a channel that connects the sprue to the cavity, which guides molten metal from the sprue to the gate(s) of the mold cavity in a controlled manner.

Runners are typically machined into one or both die halves and are sized to carry the required metal volume without premature solidification.

In multi-cavity dies, a runner may branch out like a network to feed multiple areas evenly.

Gate

The gate is the final opening that connects the runner to the mold cavity. It is usually a narrow section that controls the flow of molten metal into the cavity.

Depending on the part design and desired metal flow characteristics, the gate can have various shapes, such as rectangular, fan-shaped, or tapered.

Once the part is solidified, the gate typically breaks off or is trimmed from the casting.

A well-placed gate promotes even filling of the mold and minimizes issues like air entrapment or cold shuts.

Ejector System

The ejector system’s function is to safely remove the casting from the cavity once it has solidified and the mold halves separate.

It usually consists of multiple ejector pins, and sometimes ejector plates or sleeves.

Ejector pins are slender steel rods that contact the casting in less critical areas to push it out without damaging it.

They are all attached to an ejector plate that moves them in unison, and return pins or springs pull the ejector plate and pins back into position for the next cycle.

Cooling System

The cooling system’s primary function is thermal regulation.

A network of cooling channels is drilled or formed within the mold blocks, allowing water or oil to circulate through the mold.

These channels run close to the cavity and core inserts without contacting the molten metal, thereby absorbing heat from the metal through the mold material.

We position properly designed cooling channels to distribute cooling evenly across the mold, preventing hot spots that would cause warping or uneven solidification.

These channels also significantly influence cycle time—efficient cooling accelerates part solidification, allowing earlier mold opening and boosting production speed.

Venting System

Vents are small, intentional escape pathways in the mold that allow gases to exit the cavity as it fills with metal.

Without proper venting, trapped air in the cavity would compress and form gas porosity or cause incomplete filling and surface defects in the casting.

Vents are often narrow grooves or gaps along the parting line or at the far ends of the cavity where the metal flow finishes.

Some molds include overflow wells or vent plugs in deep areas to help capture expelled air and any impurity or oxide skins carried with the flow.

Haichen mould installation Experience

Installing a die-casting mold is a systematic project; we must strictly control every stage from mold inspection, equipment preparation to installation and commissioning.

Through scientific and standardized operation and timely maintenance.

It can effectively improve production efficiency, prolong the life of molds, and ensure product quality.

At the same time, die casting engineers need to continuously optimize the process parameters according to production needs to improve the overall production level.