Die casting machine boosting cylinders features:Their ability to multiply system pressure, by providing extremely high and stable final injection pressure, ensures that molten metal fills the mold cavity rapidly and densely in an instant, thereby directly improving the internal quality of the casting, production efficiency, and process stability.

In die casting, extremely high instantaneous pressure is require after molten metal is injecte into the mold to complete the final filling and solidification process.

The role of the booster cylinder is to rapidly increase the system pressure to the required high pressure at the end of the injection phase, typically several times the system pressure.

This precise high-pressure control is crucial for castings with complex structures and high mechanical property requirements.

This article explains the key features and technical advantages of boosting cylinders and how HAICHEN turns engineering practice into reliable productivity for customers.

Die casting machine boosting cylinders features

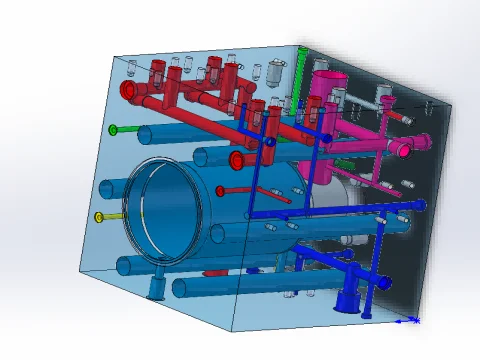

Die casting machine booster cylinder is a key component use to increase the pressure of hydraulic oil in die casting machine. Booster cylinder by converting low pressure hydraulic source into high pressure power, so as to realize the effective pressurization of the injection system.

Here are the die casting machine boosting cylinders features:

- Increased Force Output

- Compact and Space-Saving Design

- Customization Options

- Enhanced Precision and Control

Increased Force Output:

Boosting cylinders can significantly amplify the pressure generated by air or hydraulic systems, allowing die casting machines to generate much higher force without increasing the initial power supply.

This is essential for tasks like metal stamping and operating heavy machinery.

Compact and Space-Saving Design:

Despite their ability to generate significant force, boosting cylinders have a compact design.

This allows them to be integrate into existing die casting systems without requiring significant modifications or taking up valuable floor space.

Customization Options:

Boosting cylinders can be tailore to suit specific applications and requirements.

This flexibility allows manufacturers to optimize the cylinders for their unique die casting needs, ensuring seamless integration into existing setups.

Enhanced Precision and Control:

Boosting cylinders maintain exceptional precision and control, which is crucial in die casting processes that demand intricate detailing and accuracy.

This minimizes the risk of errors and rework.

Die casting machine boosting cylinders advantages

- Improved Efficiency and Productivity

- Energy Efficiency

- Enhanced Safety and Reliability

- Versatility Across Industries

Improved Efficiency and Productivity:

The increased force output allows die casting machines to operate more efficiently, improving both speed and precision in industrial settings.

This leads to faster production cycles and higher overall productivity.

Boosting cylinders are designe to maximize output while minimizing energy input.

Energy Efficiency:

They require less power to operate because they amplify the existing pressure within a system, reducing energy consumption and operational costs.

Enhanced Safety and Reliability:

Modern boosting cylinders are built with high-quality materials and undergo rigorous testing, resulting in durable and reliable components that require minimal maintenance. This leads to reduced downtime and increased cost-effectiveness.

Versatility Across Industries:

Boosting cylinders are highly adaptable and can be use in various industries, including automotive assembly, aerospace manufacturing, and material handling. Their ability to handle high-pressure applications makes them ideal for diverse operational requirements.

HAICHEN Booster Cylinder: Engineering Validation and Reliable Application

HAICHEN understands the critical role of the booster cylinder as the “heart” of the injection system. Base on deep engineering practice in die casting, the design and application of HAICHEN booster cylinders aim to ensure durable, stable, precise, and reliable high-pressure output, advantages that have been repeatedly proven in actual production.

- Engineering Validation Based on Extensive Operating Data

- Deep Customization and Integration with HAICHEN Machines

- Reliability Performance in Long-Term Continuous Production

Engineering Validation Based on Extensive Operating Data

The design parameters of HAICHEN booster cylinders are not just theoretical calculations but are derived from massive operational data accumulated from serving numerous customers. For instance, producing new energy vehicle motor housings requires extremely fast and stable pressure buildup during the intensification phase to ensure the casting’s high electrical conductivity. The response speed and pressure stability of HAICHEN booster cylinders have been continuously optimized through such demanding applications.

Deep Customization and Integration with HAICHEN Machines

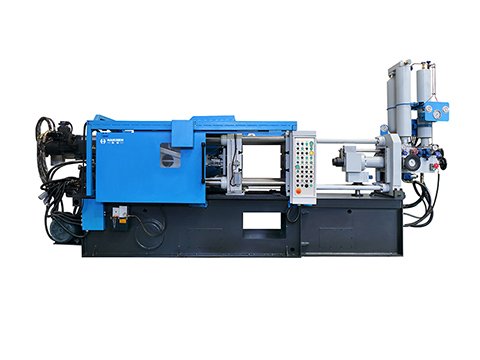

HAICHEN’s booster cylinders are not standalone components. They are designed and calibrated in integration with the hydraulic and control systems of HAICHEN die casting machines. This deep integration minimizes the response delay from the control signal to the booster cylinder’s action. Whether it’s a 650-ton machine producing large structural parts or a 280-ton machine making precision components, the performance curve of the booster cylinder is specifically match to fully realize the machine’s potential.

Reliability Performance in Long-Term Continuous Production

The reliability of the booster cylinder directly impacts the uptime of the production line. HAICHEN booster cylinders undergo fatigue and pressure-holding tests that far exceed standard requirements before leaving the factory. One customer reported that during three-shift continuous production using a HAICHEN machine, the booster cylinder maintained its core seals in good condition and pressure decay within specification even after over 500,000 injection cycles, effectively ensuring production continuity and schedule fulfillment.

HAICHEN Boosting Cylinders: Engineering Practice Driven by Data

HAICHEN sees the boosting cylinder as the “heart” of the die casting machine’s power system. Its design and validation come from analyzing massive amounts of field data and deep engineering.

- Performance Optimized by Data

- Deep Integration with the Complete Machine System

- Reliability Proven in Long-Term Continuous Production

Performance Optimized by Data

HAICHEN cylinder design parameters are not just theoretical. They are continuously optimized based on huge amounts of operating data from serving many customers. For example, making new energy vehicle motor housings needs extremely fast and stable pressure buildup during intensification to ensure high density and conductivity. The response speed and pressure stability of HAICHEN cylinders have been repeatedly tested and improved in such demanding applications.

Deep Integration with the Complete Machine System

HAICHEN boosting cylinders are not standalone parts. Their design and calibration are deeply integrated with the hydraulic and control systems of HAICHEN die casting machines. This integration minimizes the delay between the control signal and the cylinder’s action. Whether for a 650-ton machine making large structures or a 280-ton machine making small precision parts, the cylinder’s performance curve is specially matched to the machine’s full potential.

Reliability Proven in Long-Term Continuous Production

The cylinder’s reliability directly affects production line uptime. HAICHEN cylinders must pass fatigue and pressure-holding tests that far exceed standard requirements before leaving the factory. One customer reported that after over 500,000 injection cycles in three-shift continuous production with a HAICHEN machine, the boosting cylinder’s core seals remained in good condition and pressure decay was within spec. This effectively ensured production continuity and on-time delivery.

Haichen Die casting machine boosting cylinders

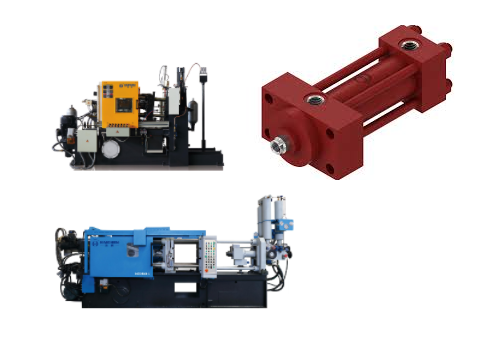

Haichen is a die casting machine factory located in Ningbo, China, mainly supplying cold chamber die casting machine and hot chamber die casting machine. Besides machines, we also supply die casting auxiliary equipments.

In the die-casting process, Haichen’s booster cylinder can provide stable and strong pressure to ensure that the molten metal can be uniformly and fully filled with all corners of the mold to reduce porosity, shrinkage and other defects, and improve the denseness and quality of the castings.

Die casting machine booster cylinder plays a vital role in modern industrial production, and its design and optimization directly affects the quality of products and production efficiency. Through continuous technological innovation and improvement, the application of booster cylinder has a broad prospect.