Force casting optimization in die casting involves enhancing the injection parameters and mold design to improve part quality, reduce defects, and increase production efficiency.

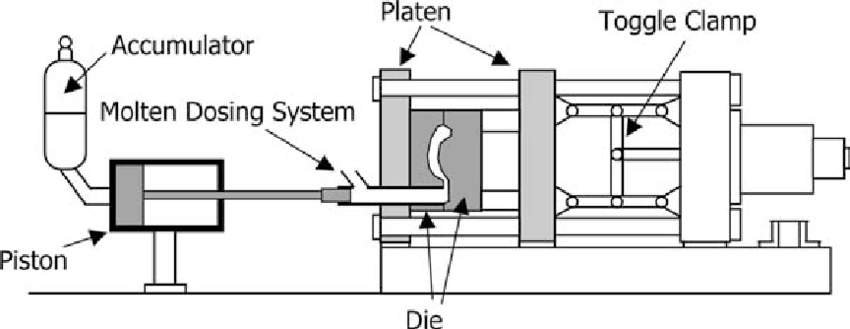

Die casting is a precision manufacturing process that involves injecting molten metal into a mold cavity under high pressure.

One of the critical aspects of this process is force casting optimization, which ensures that the molten metal flows smoothly and fills the mold cavity uniformly.

This article will explore the concept of force casting optimization and its significance in the die casting process.

Additionally, we will discuss the importance of real – time monitoring, advanced technologies, and best practices in maintaining consistent and efficient operations.

What is Force Casting Optimization?

Force casting optimization refers to the process of fine – tuning the injection parameters to ensure optimal flow and filling of the mold cavity. This involves adjusting the injection speed, pressure, and timing to achieve consistent and defect – free castings. Proper optimization can significantly reduce the risk of defects such as porosity, cold shuts, and incomplete filling.

Importance of Force Casting Optimization

- Consistent Part Quality

- Reduced Defects

- Improved Efficiency

Consistent Part Quality

Optimizing force casting ensures that each casting is produced with consistent dimensions and surface quality. This is crucial for applications where tight tolerances and high – quality finishes are required.

Reduced Defects

By optimizing the injection parameters, manufacturers can minimize common defects such as porosity, cold shuts, and incomplete filling. This leads to higher – quality castings and reduced scrap rates.

Improved Efficiency

Force casting optimization can improve the overall efficiency of the die casting process. By ensuring that the molten metal flows smoothly and fills the mold cavity uniformly, manufacturers can reduce cycle times and increase production output.

Optimization Techniques

- Simulation Software

- Real – Time Monitoring

- Process Control Systems

Simulation Software

Modern die casting machines, like those from HAICHEN, often come equipped with advanced simulation software. This software allows engineers to model the injection process and predict potential issues before production begins. By simulating different injection parameters, manufacturers can identify the optimal settings for their specific application.

Real – Time Monitoring

Real – time monitoring systems provide valuable data on the injection process. By monitoring parameters such as injection speed, pressure, and temperature, manufacturers can make real – time adjustments to ensure optimal performance. HAICHEN’s machines are equipped with advanced monitoring systems that provide detailed insights into the casting process.

Process Control Systems

Process control systems play a crucial role in force casting optimization. These systems automate the adjustment of injection parameters based on real – time data, ensuring consistent performance and high – quality castings. HAICHEN’s machines feature advanced process control systems that provide precise control over the injection process.

Optimization Technology and HAICHEN’s Practices

- Advanced Simulation Software

- Real-Time Monitoring and Data Analysis

- Precision Process Control System

- Synergistic Optimization of Mold and Process

Advanced Simulation Software

Modern die-casting machines, such as those offered by HAICHEN, are typically equipped with advanced simulation software. This software allows engineers to simulate the injection process and predict potential problems before production begins. By simulating different injection parameters, manufacturers can determine the optimal settings for their specific applications.

HAICHEN’s Practice: HAICHEN integrates an industry-leading casting simulation module that can accurately simulate the filling process of deep-cavity, thin-walled parts such as aluminum deep frying pans in a virtual environment. Engineers can pre-optimize the gating system, venting groove location, and injection profile, thereby addressing potential air entrapment and flow mark issues before actual production, reducing trial molding cycles by more than 30%.

Real-Time Monitoring and Data Analysis

Real-time monitoring systems provide valuable data for the injection process. By monitoring parameters such as injection speed, pressure, and temperature, manufacturers can make real-time adjustments to ensure optimal performance. HAICHEN machines are equipped with advanced monitoring systems that provide detailed insights into the casting process.

HAICHEN’s Practice: HAICHEN’s intelligent die-casting machines are equipped with a fully closed-loop real-time monitoring system. This system collects displacement, speed, and pressure data of the injection punch thousands of times per second. For example, in the production of zinc alloy medals, the system can detect minute pressure fluctuations at the filling end in real time and adjust accordingly, ensuring consistent internal density in each medal and maintaining a product yield rate of over 99.5%.

Precision Process Control System

Process control systems play a crucial role in force casting optimization. These systems automatically adjust injection parameters based on real-time data, ensuring consistent performance and high-quality castings. HAICHEN machines are equipped with advanced process control systems for precise control of the injection process.

HAICHEN Practice: HAICHEN’s independently developed HPC intelligent process control system is the core of its optimization. This system not only performs traditional “slow-fast-slow” multi-stage injection but also dynamically adjusts the switching points and holding pressures of each stage in conjunction with mold temperature and molten metal temperature. In the production of complex products such as automotive structural parts, this system ensures that the injection parameters are controlled with a high precision within ±0.5% under a clamping force of 3000 tons, serving as the cornerstone for achieving large-scale, high-quality, and stable production.

Synergistic Optimization of Mold and Process

Force casting optimization relies heavily on the synergy between mold design and process parameters. A combination of proper mold thermal balance, cooling channel design, and optimized injection parameters is essential to unleashing maximum efficiency.

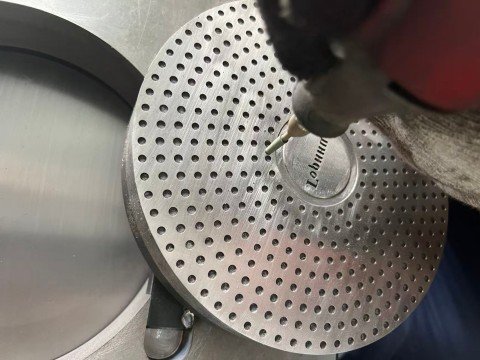

Haichen Practice: Haichen provides turnkey solutions, from mold design support to process parameter package delivery. For wear-resistant parts like road studs, Haichen’s engineering team optimizes the mold’s cooling layout to ensure rapid solidification and a fine-grained microstructure. Simultaneously, precise pressure control compensates for shrinkage, enabling castings to achieve high hardness while preventing thermal cracking, significantly improving mold life and product performance.

HAICHEN: Your Partner in Die Casting Excellence

At HAICHEN, we specialize in manufacturing high – quality die casting machines designed for precision and efficiency. Our advanced features actively maintain casting quality and process consistency in every production cycle. Whether you are starting a new project or upgrading your existing equipment, HAICHEN has the solutions to meet your needs.

Force casting optimization is essential for achieving high – quality and efficient die casting production. By optimizing the injection parameters, manufacturers can reduce defects, improve part quality, and increase production efficiency.