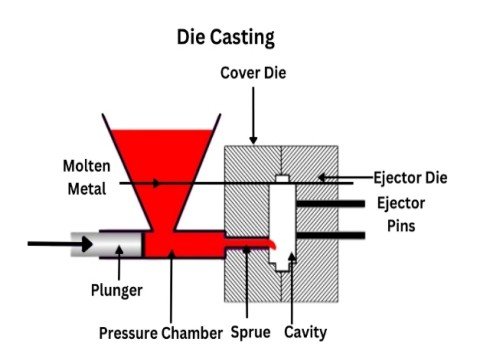

Function Purpose of Heating bush: The Heating Bush in die-casting machines ensures that molten metal maintains the ideal temperature just before injection, thus enabling seamless flow into the die.

Operating quietly behind the scenes, it thus supports the production of the high-precision components critical in modern manufacturing.

By keeping the metal at a consistent heat, the bush avoids any onset of solidification that can otherwise leave voids or defects across fine and complex geometries.

A solid grasp of this component is mandatory for any professional committed to delivering superior, repeatably high-quality castings.

This paper outlines how the bush fine-tunes the temperature equilibrium, shortens the overall cycle, and protects part integrity across industries ranging from high-performance automotive to delicate consumer electronics.

The following will comprehensively review the Function Purpose of Heating bush.

Functions of Heating Bush

- Temperature Control

- Enhanced Metal Flow

- Improved Casting Quality

Temperature Control

The core function of a heating jacket is to maintain a stable temperature for the molten metal. Keeping the metal at the correct temperature ensures that the alloy remains liquid and can be poured smoothly into the mold. Temperature fluctuations increase the risk of cold shut defects and surface blemishes. Therefore, precise temperature control is crucial for achieving flawless castings.

Enhanced Metal Flow

The heating jacket precisely maintains the molten metal at the optimum temperature, ensuring smoother metal injection into the mold. This temperature control ensures more complete filling of the mold cavity while significantly reducing the risk of defects such as porosity and shrinkage cavities within the casting.

Improved Casting Quality

The stable temperature environment provided by the heating sleeve ensures uniform cooling of the metal during solidification, significantly improving the overall quality of the casting. This constant temperature condition helps to achieve a smoother casting surface and effectively reduces the risk of internal defects such as porosity and shrinkage.

Applications of Heating Bush

- Aluminum Die Casting

- Zinc Die Casting

- Magnesium Die Casting

- Research and Development

Aluminum Die Casting

Aluminum is a commonly used metal in die casting due to its lightweight and strength. The heating bush is particularly important in aluminum die casting to maintain the molten metal’s temperature, which is typically around 660°C.

Zinc Die Casting

Zinc has a lower melting point than aluminum, and the heating bush ensures that the molten zinc remains at the optimal temperature for injection.So zinc die casting also benefits from the use of heating bushes.

Magnesium Die Casting

Magnesium is another metal that requires precise temperature control during the die casting process. The heating bush helps maintain the necessary temperature range for magnesium, which is crucial for producing high-quality castings.

Research and Development

In the development of new alloys and casting techniques, heating bushes are used to experiment with different temperature settings and optimize the casting process.

Safety Standards and Risk Control

| Risk Areas | Protective Measures |

| Personal Protection | Wear non-slip gloves and goggles; avoid loose clothing getting caught in the equipment. |

| Equipment Stability | Two people should work together (one operator, one supervisor). Secure the formwork with chains to prevent it from falling. |

| Forceful Operations | Spray loosening agent on rusted nuts. Do not use flames to heat the formwork (as this may damage the heat-treated layer). |

| Electrical Safety | Use lockout/tagout (LOTO) to ensure the power supply is completely isolated. |

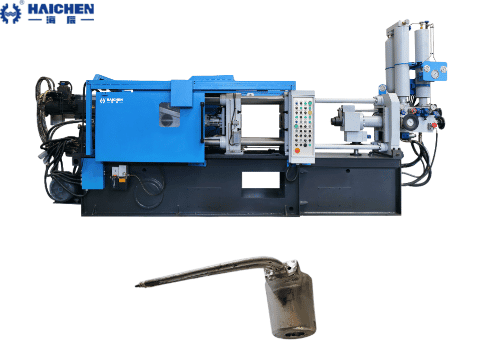

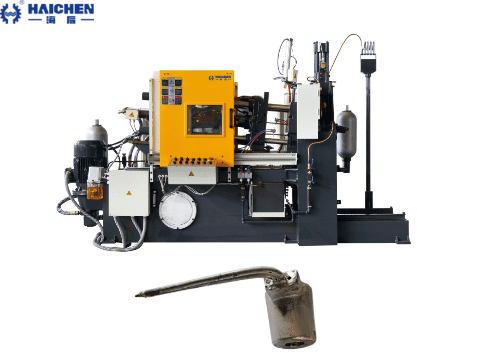

HAICHEN: The Die Casting Machine Manufacturer

A preferred partner in die-casting technology, HAICHEN builds machines that combine inventive engineering with solid craftsmanship.

Our presses withstand the high stresses of large-scale production, yet their control panels are user-friendly and their thermal zones, including the bush, stable.

Thanks to a proprietary temperature-feedback loop, HAICHEN delivers repeatability that translates into tight tolerances and minimal scrap.

For us, the heating bush is more than a heater; it is the thermal keystone that aligns chemistry with optimal flow, translating molten billets into impeccably finished dies and continuously rewarding quality.

Its function is essential to achieving consistent results in a variety of metals such as aluminum, zinc and magnesium.

By investing in advanced heating bushing technology, manufacturers can improve production efficiency and product quality.