Die casting force casting functions: fill the mold cavity, improve casting accuracy and surface quality, control internal stress and deformation etc.

Force Casting is actually another name for Pressure Casting. Its core is to force molten metal into the cavity of a steel mold (die) under high pressure, so that the metal quickly fills the complex shape of the cavity and solidifies under pressure.

In this blog, we will analyze functions of force casting in die casting mainly from below 7 aspects:

- Filling the mold cavity

- Improve casting accuracy and surface quality

- Control internal stress and deformation of castings

- Improve production efficiency

- Reduce the need for subsequent processing

- Optimize mold design and maintenance

- Adapt to a variety of materials and complex structures

The functions of force casting in die casting machine are mainly reflected in the following aspects:

Filling the mold cavity

Definition

Force casting uses high pressure to quickly inject molten metal into the mold cavity to ensure that the metal can quickly fill the entire cavity.

This process requires high pressure and high speed to prevent the metal from cooling and solidifying before entering the cavity, thereby ensuring the integrity and quality of the casting.

Mechanical Sequence of the Filling Process

- Mold Closure: Clamping force is first applied to secure the mold halves together.

- Pre-Pressure (Optional): In certain high-precision processes, a slight negative or low pressure is initially applied to the mold cavity to expel trapped gas.

- High-Speed Injection: Instantaneous injection pressure forces the melt into the mold cavity, forming a metal flow front.

- Boost/Intensification: When flow resistance increases (e.g., entering fine walls or complex flow dividers), the Boost system increases pressure to maintain flow rate.

- Vacuum Assist (if used): The vacuum valve closes at metal impact, creating a transient positive pressure to further enhance filling integrity.

- Package (Solidification Phase): After complete metal filling, cavity pressure is maintained (holding pressure) to compensate for shrinkage and eliminate internal porosity.

- Rapid Decompression/Mold Opening: After solidification is complete, the holding pressure is quickly released, allowing the mold to be opened for part removal.

Key Influencing Factors

- Alloy Viscosity and Temperature: High temperatures reduce viscosity and therefore the required injection pressure.

- Wall Thickness and Geometric Complexity: Thinner walls and more diversions require higher transient pressure or a boost system.

- Mold Design (Gate, Runner, Vent): Appropriate gate size and vent holes can reduce filling resistance and lower required pressure.

- Machine Performance: The maximum hydraulic system pressure, clamping force, and boost system response speed determine the minimum achievable wall thickness and maximum dimensions.

Improve casting accuracy and surface quality

High-pressure injection can reduce air inclusions during metal flow and reduce the generation of defects.

Such as pores, thereby improving the mechanical properties and surface finish of the casting.

In addition, the reusability of the mold during force casting also makes the casting have higher dimensional accuracy.

Enhancing Casting Precision

Function: By subjecting metal to high-pressure ‘impact’, gas resistance is eliminated, enabling precise filling of thin-walled and complex structures.

Eliminating gas resistance: High pressure overcomes surface tension between molten metal and air, preventing ‘short shot’ defects.

Prevents cold shuts: In multi-cavity moulds, high-pressure injection synchronously fills all cavities, preventing dimensional distortion caused by cooling and contraction in isolated sections.

Enhances mechanical strength: The dense microstructure induced by high pressure increases casting hardness and impact resistance.

Enhancing Surface Quality

Function: High-pressure, steady flow minimises flow defects, resulting in a smooth surface finish.

Eliminating Vortex Flow: High-pressure injection typically involves high-speed injection, enabling the melt to form a ‘straight flow’ within the mould, thereby reducing turbulence.

Prevents porosity/shrinkage cavities: High pressure facilitates superior material feeding during solidification, preventing internal voids caused by shrinkage.

Enhanced surface finish: High-pressure filling achieves more complete filling, resulting in smoother metal-mould contact surfaces that typically require less machining.

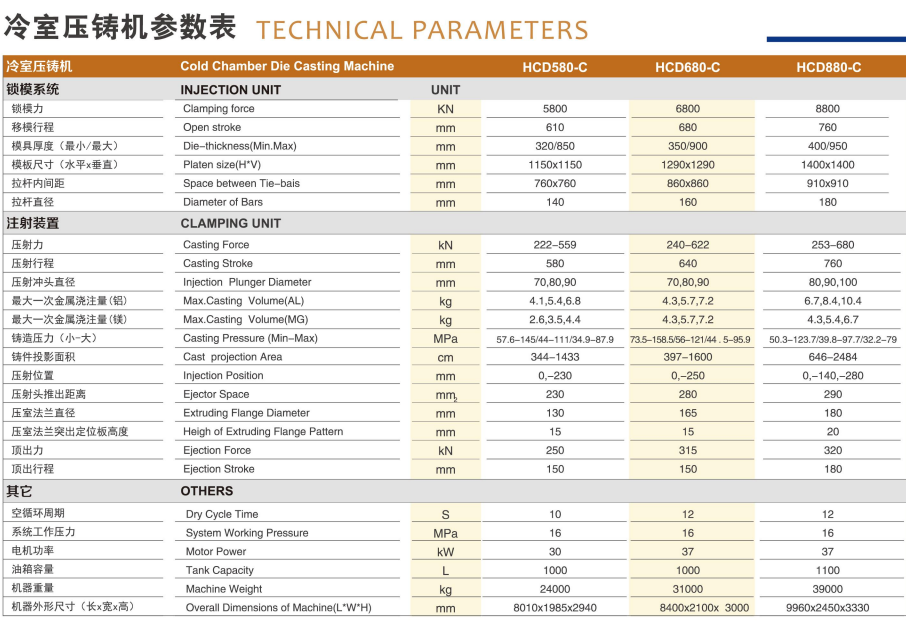

HAICHEN’s Technology for Force Casting in die casting

- Solve Porosity in Automotive Components

- Our Systems Ensure Precision and Repeatability

Solve Porosity in Automotive Components

When producing aluminum transmission housings, one of our customers faced high rejection rates due to internal porosity. HAICHEN engineers analyzed their process and identified inconsistent intensification pressure as the root cause. We adjusted the pressure build-up profile and timing on their HAICHEN cold chamber machine. This optimization ensured a more robust final pressure phase. The result was a 70% reduction in porosity-related scrap, significantly improving part strength and yield.

How Our Systems Ensure Precision and Repeatability

HAICHEN machines feature advanced servo-hydraulic systems and digital controllers. These systems provide unmatched control over injection speed and pressure curves. Every shot follows the exact same programmed path, ensuring part-to-part consistency. This reliability is a core advantage for high-volume production.

As a professional die casting machine manufacturer, HAICHEN’s expertise goes beyond building robust frames. We understand that precise control over the functions of force casting in die casting is what transforms molten metal into high-value components. Our machines deliver the power, speed, and most importantly, the precision needed to optimize this critical phase.

Control internal stress and deformation of castings

Force casting can effectively reduce residual stress and deformation inside the casting by precisely controlling the injection speed, pressure and holding time.

For example, by optimizing the layout and parameters of the injection system, casting defects caused by uneven pressure can be reduced.

Eliminating the Risk of Cold Cracks

During the solidification process in casting, the transition of metal from liquid to solid state induces volumetric contraction.

If the solidification front is constrained by the mould, tensile stresses develop internally. When these tensile stresses exceed the material’s strength, hot cracks occur.

Function of Force Casting

Through extremely high injection velocity and pressure, the molten metal forms a ‘thermal wall’ effect as it enters capillaries and thin walls.

This effect fills all voids, ensuring no ‘defective’ points exist to concentrate stresses during solidification. Consequently, the risk of cracking is significantly reduced.

Promoting ‘Uniform Solidification’

The ideal solidification process proceeds uniformly from the exterior towards the interior.

The role of Force Casting

High pressure facilitates efficient thermal conduction between the metal and the cold mould walls, accelerating solidification near the mould walls (Thermal Conductivity).

Simultaneously, the metal is compacted under high pressure, achieving greater density and a higher thermal conductivity coefficient.

This temperature gradient from the mould walls towards the core cavity aids in forming a uniform shrinkage stress field, preventing stress concentration caused by localised undercooling.

Improve production efficiency

Force casting is a high-speed casting process that can complete the production of a large number of complex-shaped parts in a short period of time.

This rapid prototyping capability makes it an important part of modern manufacturing.

Upgrading Mechanical Parameters

This pertains to enhancing the performance metrics of the die-casting machine itself, such as increasing injection force and clamping force.

Reduced cycle time

Higher injection force accelerates filling speed. Combined with optimised opening and closing times, cycle time can be reduced by over 10%.

Lowered scrap rate

Sufficient clamping force prevents flash or cold-shot defects caused by excessive mould clearance.

Reduce the need for subsequent processing

Since force casting can produce castings close to the final shape, the need for subsequent machining is reduced. This not only reduces production costs, but also improves production efficiency.

Optimize mold design and maintenance

Force casting places higher demands on mold design and maintenance. For example, the mold needs to withstand the mechanical stress caused by high-pressure injection, and regular inspection and maintenance are required to ensure its stable performance.

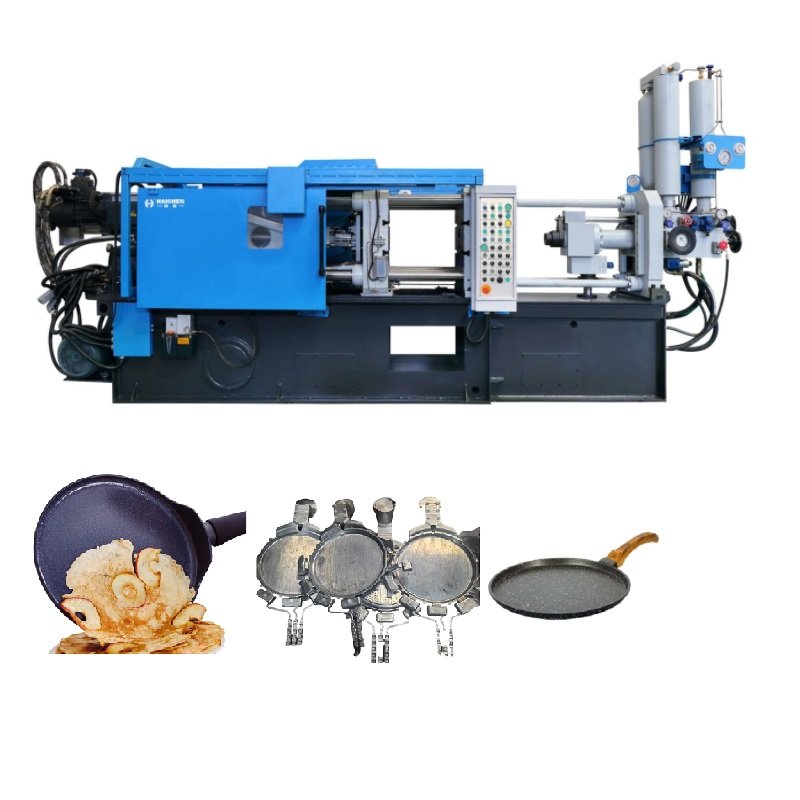

Adapt to a variety of materials and complex structures

Force casting is suitable for a variety of non-ferrous metal materials (such as aluminum, zinc, copper, etc.) and can produce parts with complex geometries. This flexibility makes it widely used in aerospace, automotive manufacturing and other fields.

Force casting in die casting machine plays a key role in the die casting process, achieving efficient and high-quality metal forming through high-pressure injection, while optimizing mold design, improving production efficiency, and reducing the need for subsequent processing.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.