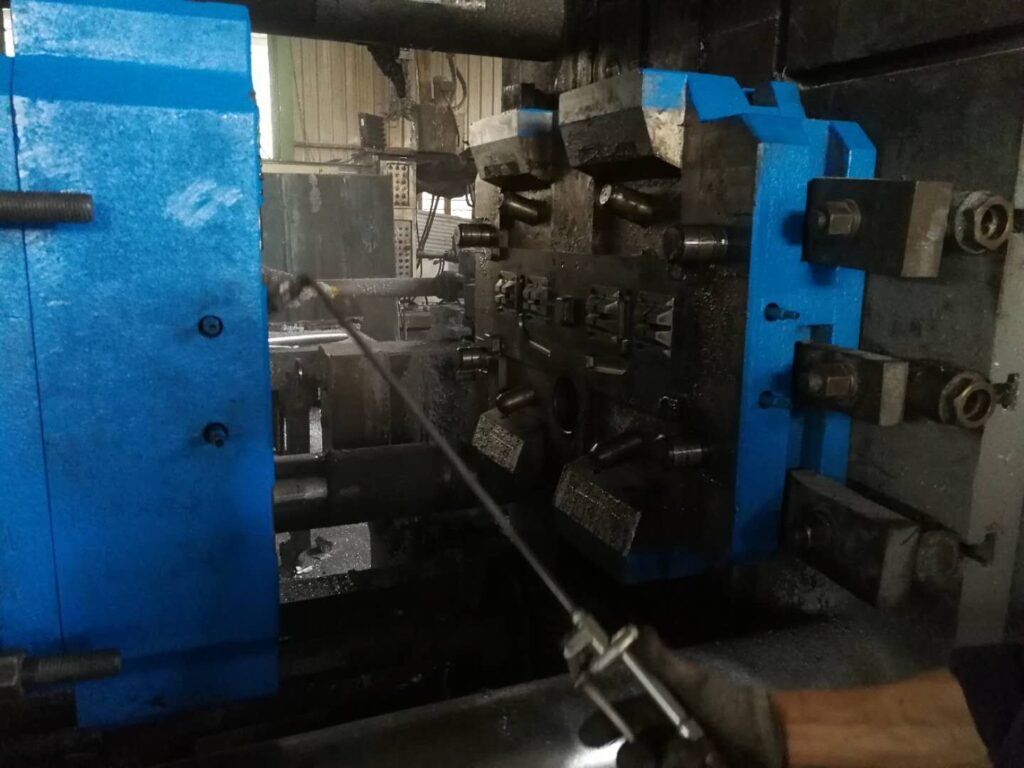

A high-pressure casting platen is a crucial component in die casting machines, designed to withstand and distribute the high pressures required for injecting molten metal into the mold cavity, ensuring precise part formation and uniformity.

Within the high pressure die casting framework, the platen is a pivotal part that supports the mold while . Also providing vertical and horizontal alignment and stability throughout the casting cycle.

Clearly, the casting cycle is dependent upon the platen in terms of quality and productivity.

In the sections that follow, we shall enumerate the underlying considerations pertaining to performance of the high pressure casting platen. As well as their importance in the die casting process.

Core Definition and Structural Components of a High-Pressure Die Casting Platform

In a die casting machine, the high-pressure die casting platen is the high-pressure die casting core load-bearing component. A frame system composed of a high-strength steel plate gives the casting zero mold deformation with clamping forces exceeding 1000 tons. It usually consists three modules that are:

- Stationary Platen: This is found at the injection end where the cover die is mounte and is in alignment with the injection system (e.g. barrel).

- Moving Platen: Hydraulically or mechanically driven, it controls the stroke of the ejector die to open or close the die. It affects flash control on the casting as well.

- Rear Platen: It has the capability to slide along tie rods allowing it to adapt to different mold thicknesses within a range of ±200mm which improves equipment versatility.

The Role of the Platen in High Pressure Casting

The platen acts as a bottom support for the mold in the HPDC machine. It is a critical component which helps in sustaining the high pressures and temperatures of the entire casting process. The platen is responsible of maintaining alignment throughout the operation.

The platen’s main functions include:

- Supporting the Mold: The platen assists to keep both halves of the mold to be capture in the proper positioning to ensure alignment during injection of molten metal.

- Ensuring Precision: High precision platens reduce the amount of tolerances in parts which leads to consistent high quality castings.

- Aiding in Efficiency: The platen is responsible for providing the correct responsiveness as it assists in the operation of smooth cycles of mold opening and closing which improves the productivity of the entire operation.

Key Factors in Platen Design and Performance

- Material Selection

- Precision Engineering

- Thermal Management

- Load Capacity

Material Selection

The material for the platen must be strong and durable. Common materials include high-strength steel and cast iron. The selection of the material contributes to weight, strength, and thermal stability. Also, the material should be able to withstand the repeated stresses of the casting process.

Precision Engineering

The manufacturing of the platen needs to incorporate high precision. This also includes tight tolerances in the machining and final machining to ensure there is no significant gaps when the mold is aligne and is minimal wearing over time.

Thermal Management

During the casting operation, the platen must endure the thermal stresses associated with the process. To reduce thermal deformation, thermal management techniques like cooling channels and heat-resistant coatings can be applie to aid in temperature consistency.

Load Capacity

The platen must possess adequate load capacity to sustain the mold’s weight as well as endure the severe pressures resulting from the injection of metal. Proper structural design alongside adequate load distribution are necessary to prevent deformation and ensure extended reliability.

HAICHEN’s High – Pressure Casting Platen Solutions

- Advanced Materials and Design

- Precision Engineering

- Customization and Flexibility

- Integrated Safety Features

Advanced Materials and Design

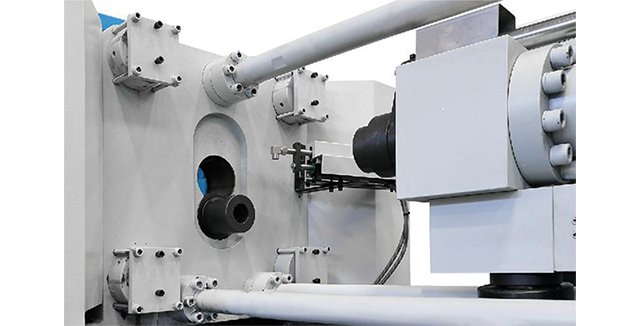

HAICHEN’s high – pressure casting platens are engineere using advanced materials and design principles to ensure durability and reliability. Our platens are made from high – strength steel and are design to withstand the demanding conditions of the die – casting process. This ensures long – term performance and reduces the need for frequent replacements.

Precision Engineering

Our platens are manufactured with precision engineering to provide accurate alignment and consistent pressure application. Each platen is carefully machine to ensure that the mold is held securely and aligne correctly. This precision engineering helps minimize defects and ensures that each part produced meets the highest quality standards.

Customization and Flexibility

HAICHEN offers a range of high – pressure casting platens to meet the specific needs of different die – casting operations. Our platens can be customize to accommodate various mold sizes and configurations, ensuring optimal performance for each application. This flexibility allows manufacturers to achieve the best possible results, regardless of the complexity of their production requirements.

Integrated Safety Features

Safety is a top priority at HAICHEN. Our high – pressure casting platens are equipped with advance safety features to protect operators and ensure a safe working environment. These features include emergency stop mechanisms, safety guards, and protective covers, which help prevent accidents and ensure smooth and efficient operation.

HAICHEN: Your Partner in High Pressure Casting

We at HAICHEN take pride in designing and producing high pressure die casting machines which are built to the highest standards. The advanced platens of our machines are a testament to the precision, durability, and reliability they are built to withstand. With thorough knowledge in material science, precision engineering, and thermal management, we guarantee the highest functioning platens that yield consistent, high-quality castings.

Why Choose HAICHEN?

- Advanced Technology: Our platens are make from high-strength materials and are engine with precision to ensure consistent performance.

- Custom Solutions: We offer customized platen designs to meet specific production needs, ensuring optimal performance for your casting operations.

- Reliability and Support: Our commitment to quality and reliability is backe by comprehensive after-sales support, including technical assistance and maintenance services.

- Innovation: As a leading manufacturer, we continuously invest in research and development to improve our products and provide cutting-edge solutions to our customers.

The high pressure casting platen in the HPDC process significantly impacts the casting operation’s efficiency and quality. Since precision machining, ideal metallurgy, thermal management. And load capacities are essential, optimal performance is achieve through careful material selection.