Plunger Tips are the end part and most critical element of the shot end assembly. Its role is to contact the molten metal and force it through the sleeve and into the die cavities.

It’s also a part of the injection system in a die casting machine, and it plays a vital role in ensuring the quality of the cast parts.

They must withstand extreme heat and pressure, leading to materials like copper alloys, hot work tool steels.

And advanced ceramics, chosen for properties like high thermal conductivity, strength, and wear resistance, ensuring quality parts, minimizing defects, and extending tool life.

Proper design and material selection prevent issues like metal leakage, turbulence, and sticking, enhancing efficiency.

What is plunger tip?

Plunger tips are components used in the shot sleeve of a die casting machine.

They are designed to help regulate the flow of molten metal into the die cavity, ensuring castings are produced accurately and with minimal defects.

They are often custom designed to fit the specific machine model and can come in various shapes and sizes to suit different casting applications.

Plunger tips play an essential role in various industries, including automotive, aerospace, and consumer goods.

The material requirements for plunger tips can be challenging, as they must withstand the high temperatures and pressures involved.

As an essential component in the shot sleeve of die casting machines, using the best possible solution for your plunger tips will result in higher-quality end products and less downtime.

Plunger Tips Material and Design

- Copper Titanium Alloy

- Other Copper Alloys

Copper Titanium Alloy:

- Copper titanium tips are a popular choice due to their excellent combination of high wear resistance and thermal conductivity.

- These tips are made from 100% beryllium-free alloy, which is environmentally friendly and safe for die casting applications.

Other Copper Alloys:

- High thermal conductivity copper alloys are also widely used. For instance, Haichen offers this plunger tips.

- These materials provide superior strength, wear resistance, and thermal conductivity, which help prevent thermal shock and cracking.

Key Features and Benefits of plunger tips

- Extended Plunger Life

- Improved Shot Sleeve Life

Extended Plunger Life:

- Compared to conventional cast iron plungers, copper titanium tips offer a much longer lifespan, reducing machine downtime.

- Reduced Casting Rejections: Longer plunger life means fewer rejections due to plunger wear, leading to higher overall productivity,this is also the reason why Haichen chose it.

Improved Shot Sleeve Life:

- Copper titanium tips do not score the shot sleeve like harder materials, allowing the shot sleeve to last longer.

- Enhanced Productivity: By reducing downtime and increasing the lifespan of both the plunger and shot sleeve, copper titanium tips contribute to higher productivity.

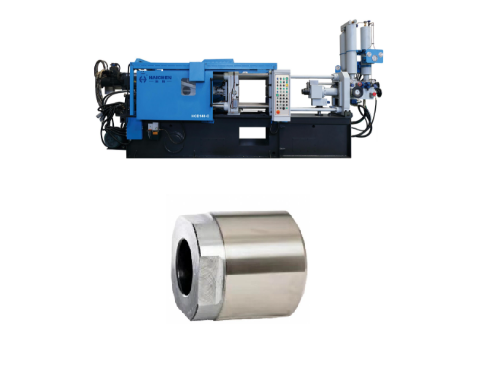

Types of Plunger Tips

- Solid Plunger Tips

- Ring Plunger Tips

Solid Plunger Tips:

- These are used in applications where a split ring is not feasible due to die or shot sleeve configuration.

Ring Plunger Tips:

- These include a wear ring that expands against the shot sleeve wall to maintain a better seal. This design reduces the risk of flash and ensures consistent shot speeds.

Functions

- Sealing and Injection

- Thermal Management

- Dimensional Stability

Sealing and Injection:

- Plunger tips must maintain a secure seal with the shot sleeve wall during the shot to prevent flash or blow-by and ensure consistent injection of molten metal.

Thermal Management:

- High thermal conductivity materials help cool the biscuit quickly, reducing cycle times and improving casting properties.

Dimensional Stability:

- The plunger tip must remain thermally and dimensionally stable throughout the shot to ensure consistent and repeatable shot velocities.

Plunger tips Applications

HPDC plunger tips play an essential role in various industries — automotive, aerospace.

And consumer goods included — that require high-quality, defect-free castings.

Engineers base the choice of material and design on the specific requirements of the casting process and the type of metal they use.

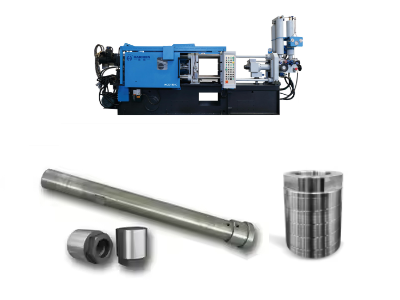

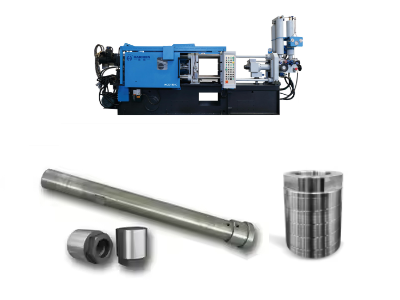

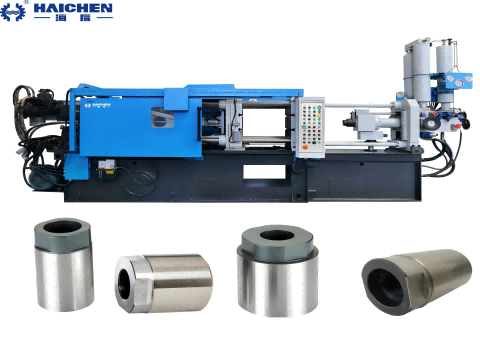

Haichen Die Casting Plunger Tips

Haichen’s Copper Plunger Tips are engineered to deliver exceptional wear resistance and outstanding thermal conductivity.

Ensuring superior performance and a significantly longer service life in High-Pressure Die Casting (HPDC) machines.

Manufactured from 100% Copper alloy, these plunger tips are not only safe for operators but also environmentally friendly, making them the preferred choice for sustainable die casting operations.

By combining advanced metallurgy with precise manufacturing processes.

Our Copper Plunger Tips help reduce casting rejections, improve productivity, and minimize downtime.

The enhanced heat dissipation ensures stable casting temperatures, reducing thermal fatigue and extending maintenance intervals.

Whether for standard or customized designs, Haichen delivers plunger tips that meet the highest standards of durability, safety, and performance for the most demanding die casting applications.

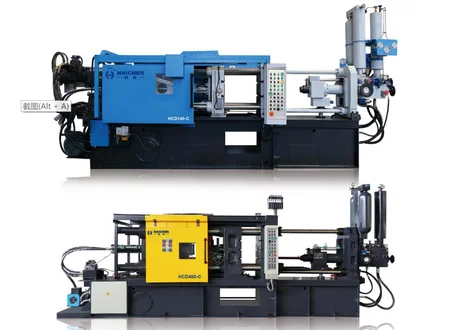

Haichen Machinery

Haichen is a well-known manufacturer of high-pressure die casting (HPDC) components, including plunger tips, shot sleeves, and other related parts.

We mainly supply cold chamber and hot chamber die casting machines.

Haichen specializes in producing plunger tips that are designed to withstand the extreme conditions of the die casting process, such as high temperatures, pressure, and mechanical wear.