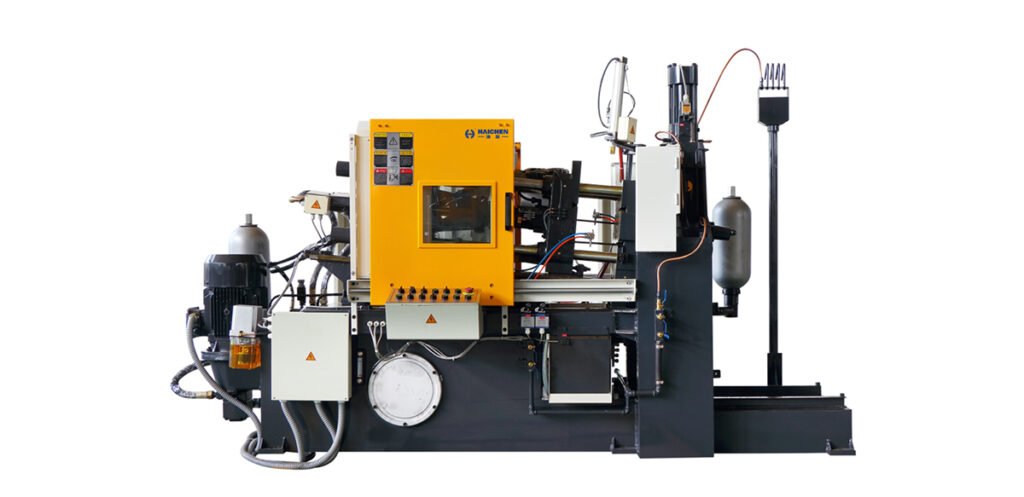

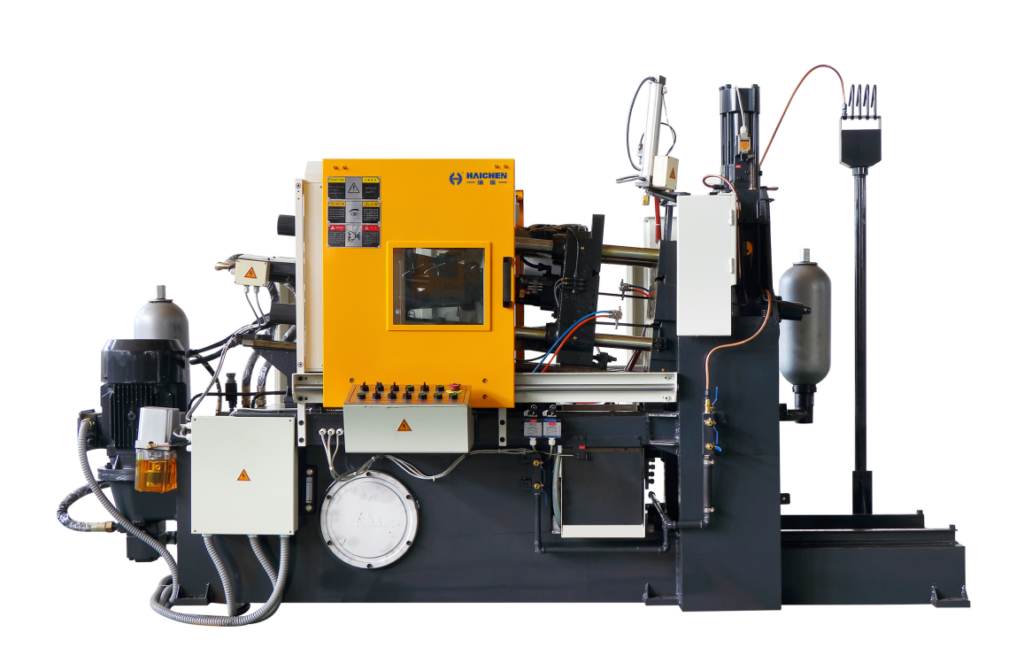

Haichen Hot chamber die casting machine

HCD-H series

The HCD-H hot chamber die casting machine offers locking forces from 350 to 1800 kN for producing Zinc and Lead parts. Haichen hot chamber die-casting machine 30 ton to 180 ton.

Hot chamber die casting machine

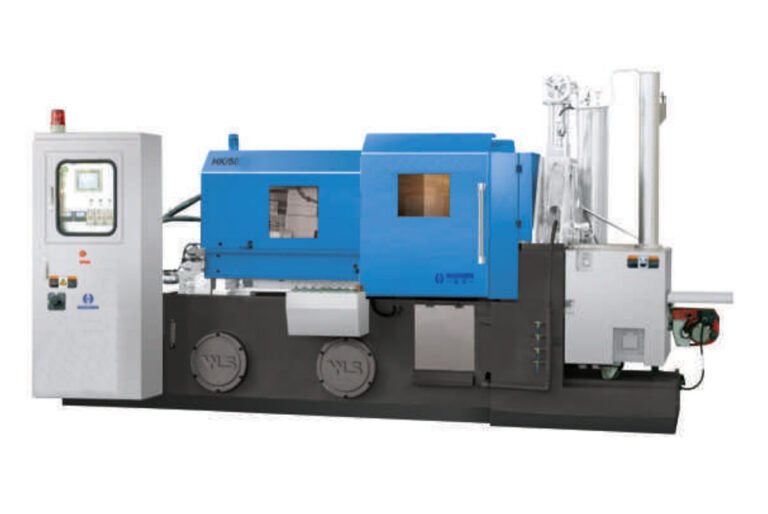

First, a hot chamber die-casting machine is a die-casting equipment that integrates a molten metal furnance with a casting machine. The working principle of a hot chamber die-casting machine is to heat the material to a liquid state through a heater, and then inject the liquid metal into the mold through a gooseneck pipe for cooling and forming.

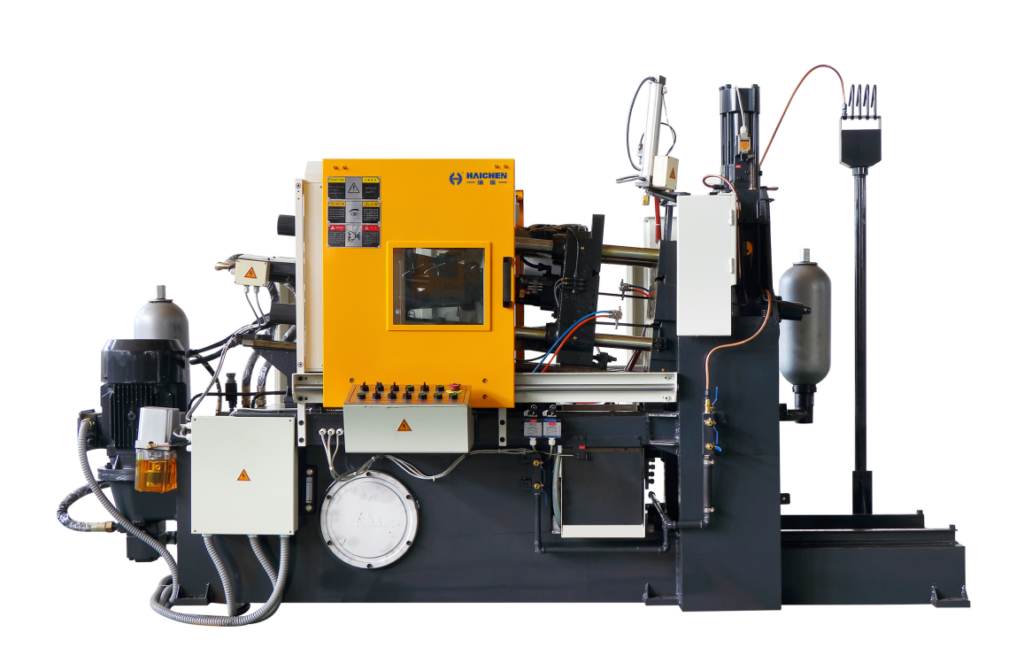

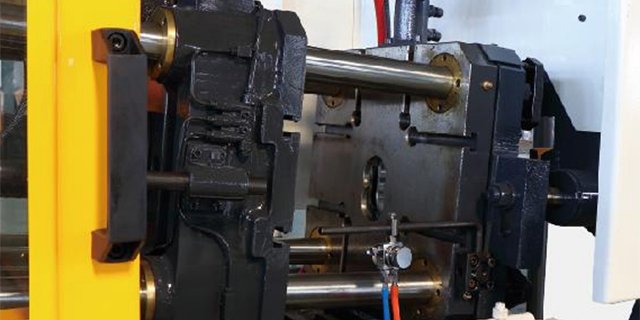

The main structure of a hot chamber die-casting machine includes injection cylinders, gooseneck, furnace crucibles, and other parts. Hot chamber die-casting machines typically use a goose neck mechanism to inject molten metal from the integrated furnace into the mold, which not only accelerates casting speed but also ensures that the castings have complex details and excellent surface smoothness.

The main difference between hot chamber die-casting machines and cold chamber die casting machines is the different feeding system. The pressure chamber of the hot chamber die casting machine is integrated with the furnace, while the pressure chamber and furnace of the cold chamber die casting machine are separate. As the gooseneck keep inside of furnance, So the hot chamber die casting machine need to feed the melt alloy to chamber.

The fully automatic hot chamber aluminum die-casting machine is an efficient metal die-casting equipment, suitable for various metals and alloy materials. Its fully automatic feeding system is twice as efficient as traditional cold chamber die-casting machines.

Hot chamber die casting machine applications

30 Ton hot chamber die casting machine

30-ton Die casting machines can produce small products such as zippers and buttons.

50 Ton hot chamber die casting machine

The 50 ton hot chamber die-casting machine is widely used in various industries to produce small metal parts

90 Ton hot chamber die casting machine

90 ton hot chamber die-casting machines can theoretically be used to produce various metal parts, including zippers, button, pipe fittings…

140 Ton hot chamber die casting machine

140-ton Die casting machines applications: electrical instruments, telecommunications, aerospace, medical equipment, etc

180 Ton hot chamber die casting machine

180-ton bigger hot chamber Die casting machines applications: 3C (computer, communication and consumer electronics), bathroom, clothing, hardware, home and other industries have wide applications

Advanced Hot Chamber Die Casting Machine Manufacturers

The injection cylinder and pressure chamber of the hot chamber die-casting machine are arranged vertically, and the pressure chamber sinks into the molten metal in the crucible of the furnace, simplifying the operation process.

Due to the continuous flow of molten metal in a closed channel, oxide inclusions are not easily trapped, and the molten metal entering the mold cavity is clean, resulting in less metal loss.

The molten liquid is always in the crucible, so there is less heat loss

Good casting quality: Due to the flow of molten metal in a closed pipeline, temperature fluctuations are small, and the chance of oxidation inclusions is small, lower pouring temperatures can be used to obtain high-quality castings. The surface quality of the castings is excellent, with improved strength and hardness

Quick view parameter of hot chamber die-casting machine

Shot unit:

High-speed press injection unit

Drive technology:

- Servo-drive

- Variable frequency motor

Clamping force:

300 – 1800 kN

Clamp system:

Optimized design for five point double toggle link machianism

Tie bar distance:

230 x 220 mm to 480 x 480 mm

Shot volume (Zinc):

1.5 – 3.5kg

Providing Hot Chamber Die Casting Machine Price

Haichen die-casting machine has a high cost-performance ratio and is directly sold by the manufacturer with transparent prices. And Haichen is well-known in the die-casting machine industry for its automated die-casting production. With years of rich manufacturing experience, we have comprehensively developed various high-performance automatic die-casting technologies.

The Haichen H series high-efficiency and energy-saving zinc alloy hot chamber die-casting machine has a price range between $13000 and $36000, still, its high-efficiency and energy-saving features can save energy costs in long-term use.

So directly purchasing from Haichen hot chamber die-casting machine manufacturers can reduce intermediate links and lower costs.

Highlight features of hot chamber die casting machine

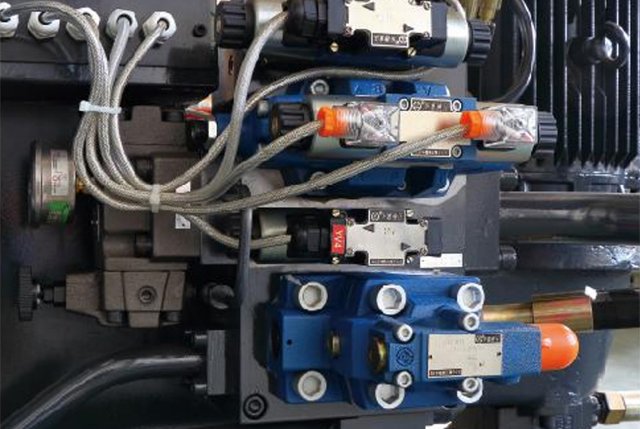

Hydraulic control

液压阀控制

The hydraulic control systmem

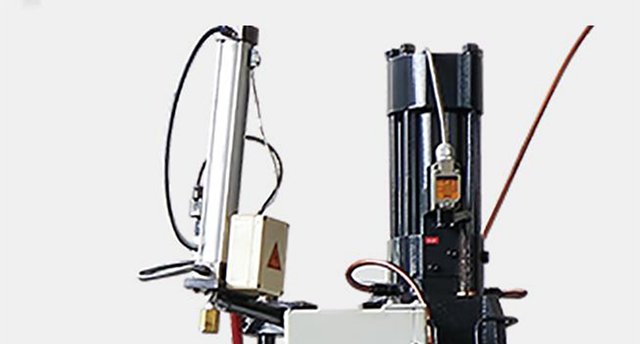

Injection frame

注射C型设计-H系列

The “H” Series hot chamber machine with special design injection unit

Injection high-speed

压射系统

High-speed press-injection device. Vertical injection makes pressure transmission more direct.

Control system

电脑控制系统

Import high-class industrial controller-screen display by international famous brand.

Clamping unit

压铸锁模

Optimized design for five point double toggle link mechanism

Mold adjustment

调模装置

Adjustment structure with celerity and equation

What is a hot chamber die casting machine?

As the chamber is kept inside of the furnace, the chamber keeps hot all the time while the machine working, so we call this casting machine is hot chamber die casting machine. And hot chamber die-casting machine is typically used for processing non-ferrous metal materials such as Zinc alloys, Lead alloys.

Hot chamber die casting process

- Metal pretreatment: Place low melting point alloys such as zinc alloys into a furnace in a hot chamber die-casting machine and heat them to a molten state.

- Mold preparation: The mold is installed on the hot chamber die-casting machine and a cooling system is set up for demolding.

- Injection process: Molten metal is injected into the mold from the furnace through a gooseneck, and the injection punch fills the metal into the mold cavity under pressure.

- Cooling forming: After the metal is cooled and solidified in the mold cavity, the die casting is taken out by opening the mold.

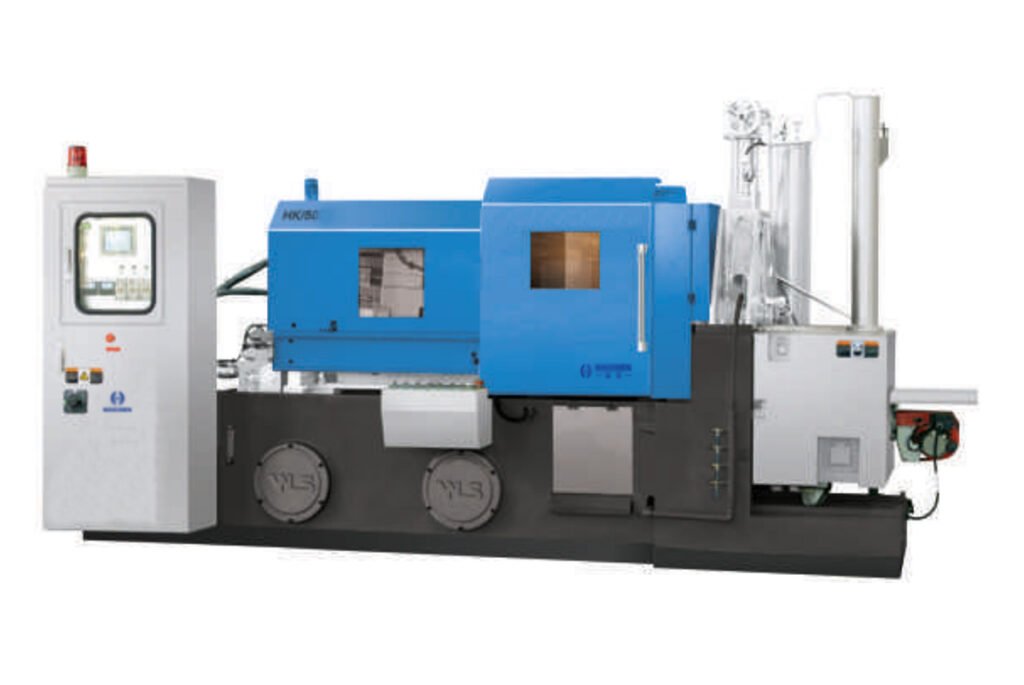

Difference between hot chamber and cold chamber die casting

Hot chamber die-casting machine:

1. The chamber(gooseneck) is immersed in an alloy liquid that maintains a constant temperature. This design allows the molten metal to be directly injected into the mold under high pressure, simplifying the operation process.

2. Used for casting low melting point metals such as zinc, copper, and lead.

Cold chamber die-casting machine:

1. The chamber and furnace are separate, and the molten metal needs to be poured from the crucible into the injection chamber for injection.

2. Used for high melting point metals such as aluminum, magnesium, copper.

What are the benefits of hot chamber die casting?

The main advantages of hot chamber die-casting machines include high production efficiency, low metal consumption, stable process, and easy automation. Due to the fact that metal alloys are always in a molten state, injection and solidification processes can be rapidly and continuously carried out, thereby improving production efficiency. In addition, the metal liquid of the hot chamber die-casting machine is automatically replenished into the injection chamber under the action of gravity and vacuum force, without the need for separate pouring, further simplifying the production process.

What are the disadvantage of hot chamber die casting?

- Limited range of applicable materials: Hot chamber die-casting machines are mainly suitable for die-casting of low melting point metals such as zinc, magnesium, tin, etc., so the material selection is relatively limited.

- Injection ratio is smaller: There is no pressure increase during the injection process, which reduces the pressure on the mold by the equipment, thereby extending the service life of the mold.

- Suitable for small and medium-sized parts: Hot chamber die-casting machines are particularly suitable for producing small and medium-sized parts, capable of producing parts with complex details and excellent surface smoothness.