Shot sleeves in die casting machines work by holding and guiding the molten metal as it is injected into the mold cavity, ensuring precise control over the flow and volume of metal to produce high-quality castings.

Shot sleeves are important parts of a machine used for high-pressure die casting (HPDC) within the die casting process.

They are necessary for proper functioning and for achieving proper timing and metal flow within the machine.

Effective shot sleeve operation makes for better die casting optimization and quality improvement for the manufacturers.

What Are Shot Sleeves?

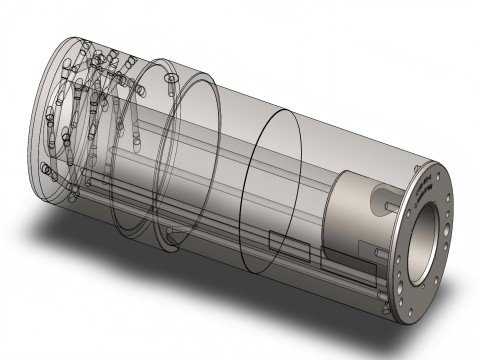

Shot sleeves are parts of die casting machine. They are the cylindrical parts that use a steel or ceramic made shot sleeve which guides and holds the molten metal until injection.

Shot sleeve’s main purpose is to:

- Help the Flow of Molten Metal: The sleeve guides the molten metal in such a way that it does not splash or excessively flow to the mold cavity.

- Prevent Metal Loss: This part retains the molten metal during the injection phase to aid the machine to have less wasted overflow.

- Metal solidification: The shot sleeve aids in the initial cooling of the molten metal, which enhances the quality of the final product.

How Do Shot Sleeves Work in the Die Casting Process?

In a standard die casting cycle, the shot sleeve functions sequentially as follows:

- Filling the Shot Sleeve

- Injection

- Cooling and Solidification

- Ejection

Filling the Shot Sleeve

The operator fills the shot sleeve with molten metal precisely to a certain level. The operator needs to measure metal precisely to ensure that the shot sleeve will inject the correct volume into the mold cavity.

Injection

The filling is then follow by the injection. The shot sleeve is then fill. A plunger or a piston moves forward filling the mold cavity under considerable speed and pressure with the molten metal.

Cooling and Solidification

The metal within the mold cavity begins to cool and solidify immediately after the injection.

Ejection

After the solidification the mold ejects the finished part. The shot sleeve needs to be fill again with metal to start the cycle again.

Importance of Shot Sleeve Design and Maintenance

Proper design and maintenance of shot sleeves are essential in any die casting operations:

- Material Selection: To ensure the life and performance of the shot sleeves, high-grade materials are essential that endure high heat and pressure.

- Surface Finish: Improving the final shot sleeve quality increases the value of the final product.

- Scheduled Maintenance: Proper maintenance scheduling which includes routine inspection tends also enables detection and prevention of problems such as sleeve, corrosion, and residual metals which could interfere in the injecting cycle and product value.

Offering sophisticated shot sleeve design and maintenance solutions, HAICHEN SHOT SLEEVES guarantees optimal performance. HAICHEN, a leading die casting machine manufacturer, equips our machines with the shot sleeves which undergo the high-pressure die casted systems. Thus, ensuring a consistent and high-quality production.

Optimizing Shot Sleeve Performance

To optimize the performance of shot sleeves in die casting, manufacturers can take several steps:

- Precision Engineering: Precisely engineer the shot sleeve to match the specific requirements of the die casting process.

- Temperature Control: Maintain consistent temperatures to prevent thermal shock and ensure uniform cooling of the molten metal.

- Lubrication and Cleaning: Regularly lubricate and clean the shot sleeve to prevent wear and buildup of residual metal.

By focusing on these areas, manufacturers can improve the efficiency and quality of their die casting operations.

Shot Sleeves are important components in the entire die casting process. They guarantee that smooth and accurate injection of molten metal into the mold cavity takes place. Proper understanding of functions and maintenance will greatly improve the die cast quality and enhance the product consistency.