Aluminium die casting working principle and process is mainly based on high pressure will be molten aluminium alloy injected into the mould cavity, and under the action of pressure rapid cooling and solidification, so as to form the required shape and size of the casting.

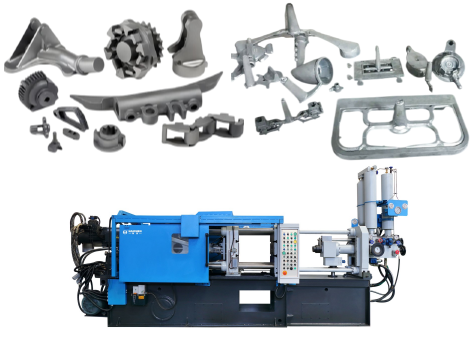

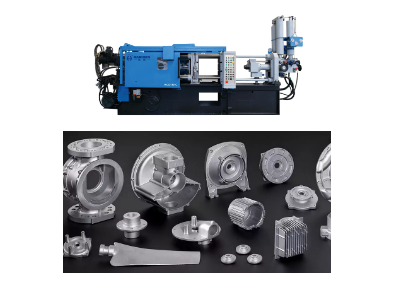

Aluminum die casting is a reusable, non-consumable manufacturing process capable of producing aluminum alloy die castings of various shapes, sizes, and thicknesses.

The aluminum die casting process also allows for the manufacture of lightweight parts, maintenance of high operating temperatures, and excellent corrosion resistance for a wide range of industrial applications.

The specific working process and key steps of aluminium alloy die casting

- Melting and treatment of aluminium alloy

- Mould preparation

- Injection of aluminium alloys

- Cooling and solidification

- Opening the mould and removing the casting

- Follow-up treatment

- Process optimisation and automation

Melting and treatment of aluminium alloy

Firstly use furnace to heat Aluminium alloy to liquid state, usually the temperature is at about 750°C, while adding appropriate amount of alloying elements (e.g. magnesium, silicon, etc.) in order to improve the mechanical properties and electrical conductivity.

During the melting process, we use vacuum degassing technology to remove gases and impurities from the aluminium liquid to ensure the quality of the castings.

Mould preparation

The mould consists of a fixed die and a moving die. The mould design needs to ensure high precision and repeatability.

The moulds are usually made of high temperature resistant hot work steel, which will not be damaged after each use.

The surface of the mould is sprayed with a release agent for subsequent mould release.

Injection of aluminium alloys

The injection piston injects the molten aluminium alloy (typically tens of MPa) into the mould cavity at high pressure.

Injection speeds of 16-80 m/s can be in 0.01-0.02 seconds.

During the injection process, the die casting machine maintains a certain pressure and time die on the mould to ensure that the aluminium alloy completely fills all cavities in the mould.

Cooling and solidification

We apply cooling means to cool and solidify the aluminium alloy in the mould.

The cooling method can be water or air cooled, depending on the mould design and process requirements.

The cooling time depends on the thickness and shape of the casting and usually takes a few minutes.

Opening the mould and removing the casting

After cooling, the die casting machine opens the mould and takes out the moulded aluminium alloy castings.

The removed castings may have burrs or surface defects, which need to be cleaned and subsequently processed.

Follow-up treatment

Clean the surface of the casting, remove burrs, flying edges and other excess parts.

Perform surface treatment such as trimming, polishing, sandblasting, etc. on the castings.

Some castings may need further heat treatment or welding to improve mechanical properties.

Process optimisation and automation

Modern aluminium alloy die casting processes incorporate automated control systems to ensure production efficiency and consistent product quality by monitoring parameters such as temperature, pressure and injection speed.

We make extensive use of high pressure vacuum die casting technology to minimise porosity and improve the internal quality of castings.

Process characteristics

High efficiency: aluminium alloy die casting can achieve high-speed injection and rapid cooling, suitable for mass production.

Precision: through precise control of injection pressure and time, we can maufacture the complex shapes and high-precision parts.

Wide range of application: widely used in automotive, aerospace, electronic equipment and other fields.

Precautions

Safety regulations need to be strictly observed during operation to avoid injuries caused by high temperature liquids or high pressure equipment.

Mould design and material selection is crucial to product quality, need regular maintenance and inspection.

Aluminium alloy die casting is a collection of high efficiency, precision and automation in one of the advanced casting process, its working principle is through the high pressure will be molten aluminium alloy into the mould cavity, and under the action of the pressure of rapid cooling and solidification to form the required shape of the casting.

This process not only improves production efficiency, but also significantly improves the quality and performance of castings.

How does die casting work step by step?

The die casting process has automation in nine detailed steps:

- Step 1 Mould Preparation

- Step 2 Preparation of the molten metal

- Step 3 Mould closure

- Step 4 Molten metal injection

- Step 5 Applying pressure and curing

- Step 6 Step 5 Cooling and Solidification

- Step 7 Opening the mould and removing the finished product

- Step 8 Post-processing

- Step 9 Cycle Start

Step 1 Mould Preparation

The mould needs to be manufactured beforehand and made sure that it is in good condition.

The mould usually consists of two parts: a fixed template and a movable template, with a cavity formed in between to hold the molten metal.

The surface of the mould is coated with a lubricant to prevent the metal from sticking.

Step 2 Preparation of the molten metal

We heat the metal to a molten state using a furnace.

Commonly used metal materials include alloys such as aluminium, zinc and copper.

In some cases, such as vacuum die casting processes, we add nitrogen during the melting of the raw material to reduce oxidation.

Step 3 Mould closure

Closing the mould to form a closed space for the injection of molten metal.

Step 4 Molten metal injection

Molten metal injecting into the mould cavity through a gate using a hydraulically or electrically actuated pressure injection unit.

This process needs to complete in a very short period of time to ensure that the metal can fill the mould quickly.

The injection rate is usually dividing into two stages: an initial low injection rate (Stage 1), following by a gradual increase in rate to complete the fill.

Step 5 Applying pressure and curing

Once the injection is complete, the mould continues to apply high pressure to ensure that the metal completely fills the mould and air bubbles are eliminated.

At this point, the metal begins to cool and gradually solidifies.

The pressure hold time depends on the type of metal and the mould design, and usually ranges from a few seconds to a few minutes.

Step 6 Step 5 Cooling and Solidification

During the cooling process, the metal gradually solidifies into its final shape.

The cooling time depends on the thermal conductivity of the material and the mould design.

Step 7 Opening the mould and removing the finished product

When the metal is fully solidified, the mould is opened and the casting is removed.

This step is usually finishing by robotic or automated equipment.

Step 8 Post-processing

The removed casting may require further processing.

For example, deburring, grinding or machining to achieve the final dimensions and surface quality required.

Step 9 Cycle Start

After completing the above steps, the mould is reclosing and ready for the next cycle.

More need to know

The aluminium alloy die-casting process involves multiple steps from raw material preparation to finished product inspection, with precise control of each step.

From mould design to the production of the final product, it is necessary to comprehensively consider the material characteristics, process parameters and equipment performance and other factors.

Through reasonable process design and strict quality control, we can produce high-quality, high-precision aluminium alloy parts to meet the demand for complex parts in the industrial field.

Choose Haichen to solve your aluminium alloy die casting production process meticulously.

Feel free to contact us by letter.