The cost of an Aluminium alloy road studs die casting machine depends on factors like clamping force, automation level, and additional features.

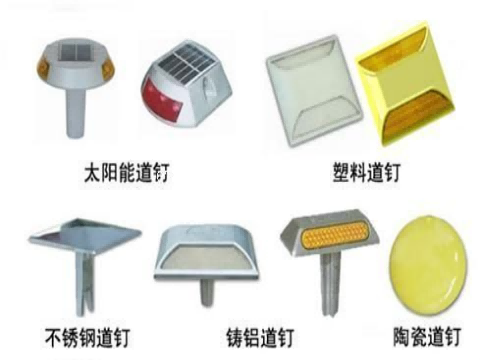

Aluminum road marking spikes are widely for highways, tunnels, airports, urban roads and other scenarios. In the production of aluminum road marking spikes, the commonly used die-casting equipment is the cold chamber die-casting machine.

Based on the search results, here’s a detailed breakdown:

Aluminum alloy road stud die-casting machines with different configurations

- Machine Cost by Clamping Force

- Key Cost Drivers

- Additional Expenses

- Cost-Saving Tips

- Example Suppliers and Price Ranges

Machine Cost by Clamping Force

Aluminum road studs are typically small parts, requiring mid-sized machines (160T–500T clamping force). Prices vary by capacity:

- Smaller Machines (160T–280T):

- 38,500–38,500–64,500 per unit .

- Example: A 280T cold chamber die casting machine for aluminum alloy parts .

- Mid-Range Machines (300T–500T):

- 77,210–77,210–118,540 per set .

- Example: Lanson’s LS400 (400T) or LS500 (500T) models .

- Larger Machines (800T–1000T+):

- Up to $208,130 for heavy-duty applications, though unnecessary for standard road studs .

Key Cost Drivers

- Automation:

- Fully automated systems (e.g., auto ladle, robotic extractors) add 20–30% to the base price .

- Tooling:

- Custom molds for road studs cost 10,000–10,000–50,000+, depending on complexity .

- Material Compatibility:

- Machines optimized for aluminum alloys (e.g., A380, ADC12) may cost slightly more than general-purpose models .

Additional Expenses

- Secondary Processes:

- CNC machining, surface finishing (anodizing, powder coating), and quality inspections add $5–20 per unit .

- Maintenance:

- Annual upkeep (e.g., die refurbishment, hydraulic system checks) costs 5–10% of the machine’s initial price .

Cost-Saving Tips

- Opt for Standardized Models:

- Pre-engineered machines (e.g., HAICHEN HCD 400-880T) reduce customization costs .

- Multi-Cavity Molds:

- Produce multiple road studs per cycle to lower per-unit costs .

- Bulk Purchasing:

- Suppliers like Ningbo Haichen or LK offer discounts for high-volume orders .

Example Suppliers and Price Ranges

| Supplier | Clamping Force | Estimated Cost | Key Features |

|---|---|---|---|

| Lanson 1 | 220T–1000T | 52,150–52,150–208,130 | ISO-certified, cold chamber, high precision. |

| HFX Precision 13 | 88T–1280T | 73,550–73,550–118,540 | Fully automated, vacuum-assisted systems. |

| Ningbo Zunhang 11 | 200T–500T | 38,500–38,500–95,790 | Specializes in automotive-grade parts. |

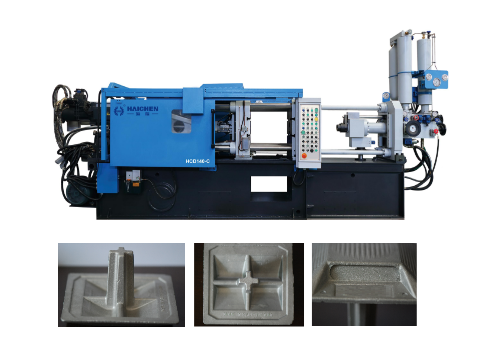

Haichen Aluminum Alloy Road Stud die casting machine?

The aluminum alloy road spike die-casting machine produced by Haichen belongs to the high-end cold chamber die-casting machine series:

- Machine type and applicable materials

- Specific models and parameters

- Technical advantages and design

- Application Cases and Industry Coverage

- Supporting services and experience

Machine type and applicable materials

Haichen’s cold chamber die-casting machine is specially for die-casting of high melting point metals such as aluminum alloys and magnesium alloys.

Due to the high melting temperature of aluminum alloys (usually over 700°C), a cold chamber design is required to separate the injection chamber from the furnace to avoid high temperature damage to the hydraulic system.

Specific models and parameters

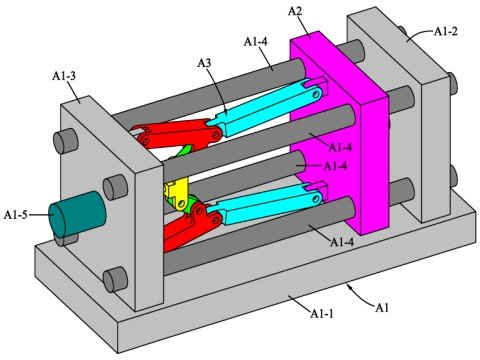

HCD 200-C model:

Detailed description of the 200-ton multifunctional cold chamber die-casting machine (HCD 200-C), with an extrusion force range of 99-250 kN, a die-casting thickness of 200-580 mm, and a maximum casting weight of 1.8 kg.

It is suitable for road spikes, automotive parts, hardware products and other fields, and can cover the production needs of transportation facility components.

HCD-C Series:

This series of cold chamber die casting machines has a clamping force of 2080 tons, and its flexibility and high precision can support the manufacturing of aluminum alloy road spikes with complex shapes.

At the same time, this series is suitable for medium-sized aluminum castings such as radiators, building materials and automotive accessories.

Technical advantages and design

High precision and stability:

Haichen die casting machine adopts Siemens PLC control system and ultra-quiet hydraulic circuit to achieve high-speed and high-pressure injection, ensuring the density and surface quality of castings.

Modular design:

The machine is equipped with adjustable mold stroke (maximum 370 mm) and injection push rod diameter (50/60 mm) to meet the needs of road spike molds of different sizes.

Safety and energy efficiency:

The system working pressure is 16 MPa, the motor power is 15 kW, and the energy-saving design is combined to reduce energy consumption. At the same time, it has passed CE certification and ISO 9001 standards to ensure operational safety.

Application Cases and Industry Coverage

Haichen cold chamber die-casting machines have been widely used in automotive parts (such as engine blocks, gearbox housings), LED lamp housings, building hardware and other fields.

As metal parts in traffic facilities, road spikes have a production process similar to the above products, and require high-pressure injection to achieve complex structure molding.

Haichen die-casting machines are used to produce “road studs”. Combined with the lightweight and corrosion-resistant characteristics of aluminum alloys, our high-precision cold chamber machines can be adapted to the mass production of aluminum alloy road studs.

Supporting services and experience

Haichen has more than 20 years of experience in Aluminum Alloy Road Studs die casting machine manufacturing, providing full-process solutions from mold design to production lines to support customer customization needs.

Its factory is located in Ningbo, Zhejiang, and is equipped with advanced machining centers to meet the research and development and manufacturing of high-precision molds.

Haichen’s cold chamber die-casting machines (such as HCD 200-C and HCD-C series) can efficiently produce aluminum alloy road spikes through high pressure, modular design and stable performance.

Our die-casting equipment technical parameters and industry case experience are fully adapted to the manufacturing needs of aluminum alloy road spikes.

At the same time, we have the OEM capability to help users select the appropriate tonnage cold chamber die-casting machine model according to the specific size and output requirements of the road spikes.

Please feel free to write or call us to learn more about the details of aluminum alloy road spike die-casting production.

More we telling

For aluminum alloy road stud production, a 160T–400T Aluminium alloy road studs die casting machine is ideal, costing 38,500–38,500–95,790. Higher automation and tooling quality justify the premium for long-term efficiency.