Hot chamber die casting machines can range in price from tens of thousands of dollars to hundreds of thousands of dollars.

The reasons for the different prices of hot chamber die-casting machines include different brands, configurations, processes, designs and other comprehensive factors.

Therefore, purchasing the most suitable die casting machine according to your own product quality level and target market positioning, and combining your own budget is the most important part of your business plan.

For example, a 50-tonne horizontal high-pressure hot chamber die casting machine from Haichen is priced from US$ 18,000.

In addition, other types of hot chamber die casting machines, such as 88-tonne and 160-tonne hot chamber die casting machines, are priced at a total of approximately $200,000 for two sets of equipment, respectively.

Thus, the price of hot chamber die casting machines varies by model, capacity and manufacturer.

What are the 2 types of die casting machines?

There are two main types of die casting machines: hot chamber die casting machines and cold chamber die casting machines.

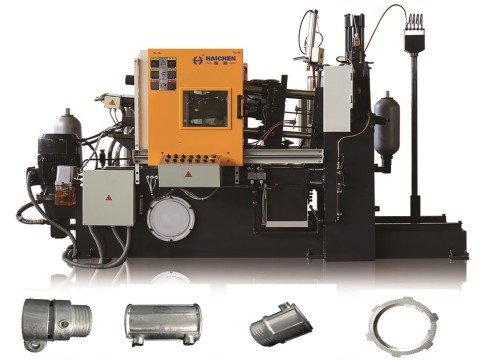

- Hot chamber die casting machine

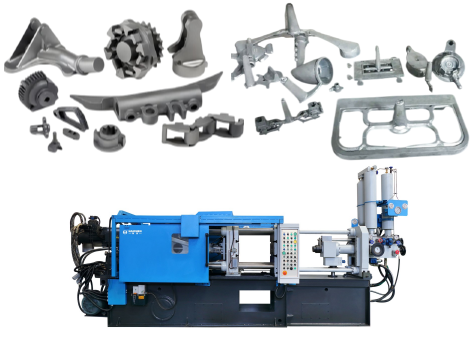

- Cold chamber die casting machines

Hot chamber die casting machine

This type of machine is suitable for low melting point metals such as zinc and magnesium.

In a hot chamber die casting machine, an on-board furnace melts the metal, which is then injected directly into the mould cavity through a gooseneck pot.

This type of machine can produce small, complex parts because they can be produced quickly and efficiently.

Cold chamber die casting machines

This type of machine is suitable for high melting point metals such as aluminium and copper.

In a cold chamber die casting machine, the metal is fed into the mould cavity from a separate furnace.

Because of the high melting point of these metals, more sophisticated cooling systems are required to control temperature and fluidity.

Cold chamber die casting machines are typically used to produce large or heavy parts because they can withstand higher pressures and temperatures.

Each of these two types of die casting machines has its own range of applications and characteristics.

Factories choose the type of machine based on the materials used in the target product and the characteristics and complexity of the parts required.

How do I choose a die casting machine?

There are several factors to consider when choosing the right die casting machine.

These include the size of the machine, the materials used, and the specific application scenario.

We recommend the following steps:

- Determine the type of die casting machine

- Evaluate the machine performance

- Calculate technical parameters and manufacturability

- Selection of suitable machine model

- Evaluate the economy and efficiency

- Consider automation and production needs

- Comprehensive consideration of other factors

Determine the type of die casting machine

Select the type of machine based on the type of metal being used.

Choose a hot chamber die casting machine for use with low melting point alloys such as zinc, tin or lead.

While for high melting point alloys such as aluminium and copper, a cold chamber die casting machine is more suitable.

Evaluate the machine performance

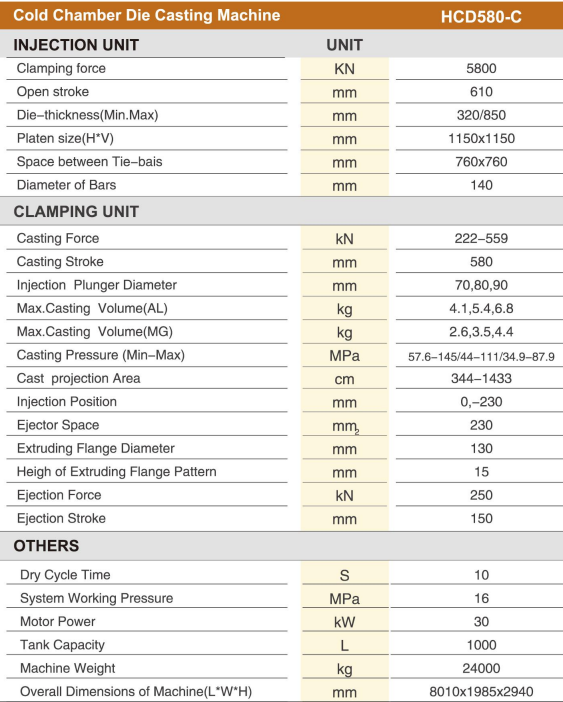

Evaluate the machine’s clamping force, injection speed and cooling capacity.

These parameters have a direct impact on casting quality and productivity.

Ensure that the clamping force of the machine is greater than the separation force generated by the metal during injection.

To prevent the mould from opening during injection.

Calculate technical parameters and manufacturability

According to technical requirements, conditions of use and specifications of the die-casting process.

Calculate the technical parameters of the die casting process and the manufacturability of the mould.

Selection of suitable machine model

According to the dimensions of the mould (or die casting) of the preliminary design and the process requirements, select the appropriate machine model.

This includes consideration of the projected area of the mould, the injection pressure and the opening stroke of the mould.

Evaluate the economy and efficiency

In actual production, assess the working performance and economic efficiency of the die casting machine.

This includes output, pass rate, operational stability and safety.

Consider automation and production needs

If the production scale is large, we recommend choosing a die casting machine that can realise fully automatic production.

To improve production efficiency and product quality.

Comprehensive consideration of other factors:

Also need to consider the service life of the machine, maintenance costs, and whether to meet the needs of future product development direction.

Through the above steps, can be more comprehensive evaluation and selection of suitable die-casting machine, so as to ensure the production of efficient and product quality.

How much is die casting?

The cost of die casting, which is affected by a number of factors.

These include the complexity of the design, the cost of raw materials, the volume of production, and the precision required.

Specifically, due to the need for custom moulds and higher initial investment costs, we usually use high strength steels for moulds that need to withstand the pressures and temperatures of the casting process.

However, once the moulds are made, the production cost per part is relatively low because the die casting process is fast and the moulds can be reused many times.

- The choice of material

- There are two main types of die casting process

The choice of material

For die casting is also important, and commonly used alloys include aluminium, zinc and magnesium.

Aluminium is one of the most commonly using alloys, suitable for high-pressure die-casting process, and has good mechanical properties and surface finish.

In addition, zinc alloys are also commonly used in die casting, especially where high precision and complex shapes are required.

There are two main types of die casting process

Hot chamber die casting and cold chamber die casting.

Hot chamber die casting is used for metals with a lower melting point, such as zinc, while cold chamber die casting is used for metals with a higher melting point, such as aluminium and magnesium.

Die casting is a metal casting process that enables molten metal to injectiing at high pressure into precision moulds to produce metal parts with complex geometries.

This process is widely used in industries such as automotive and electronics, and is favoured for its ability to efficiently produce high-quality, dimensionally consistent products.

Haichen is a company with extensive experience and technology in the field of die casting machines.

Our products cover a wide range of models from cold to hot chambers for a wide range of industrial applications, with a focus on product safety and efficiency.