To systematically avoid die casting defects, the key lies in the precise control and coordinated optimization of molds, equipment, materials, and process parameters throughout the die casting process chain.

This article will first explain how to avoid defects through die and process optimization.

It will then analyze the critical role of raw material management and equipment maintenance.

Finally, it will introduce how to build a systematic quality monitoring system and show how HAICHEN die casting machines help customers achieve this goal in real production.

Measures to Avoid Die Casting Defects

Effective measures can effectively reduce the defects in the die-casting process, improve the quality of castings and production efficiency.

- Mold Preheating

- Optimization of gate and cooling system design

- Control of injection speed and filling time

- Temperature management

- Simulation and optimization using computer-aided techniques

- Improvement of material and process parameters

- Regular maintenance of equipment

- Use of advanced analytical tools

Mold Preheating

- It is very important to preheat the mold prior to die casting, especially for large or complex parts.

- This ensures a smooth and even flow of molten metal into the mold cavity, thus reducing the risk of a cold shut.

Optimization of gate and cooling system design

- Proper gate and cooling system design can significantly improve the quality of castings.

- For example, by optimizing the location and size of the gate, it is possible to ensure a smoother flow of the molten metal and reduce the occurrence of defects such as cold seals and porosity.

Control of injection speed and filling time

- Increasing the injection speed allows the molten metal to fill the mold cavity faster, thus reducing the formation of cold seals and porosity.

- Also, controlling the filling time and pressure can help avoid defects.

Temperature Management

- Controlling the temperature of the mold and molten metal is critical to avoiding defects.

- Too high a mold temperature may lead to premature solidification of the metal, while too low a temperature may lead to incomplete filling.

- Therefore, appropriate temperature adjustments need to be made on a case-by-case basis

Simulation and optimization using computer-aided technology

- Using computer-aided casting simulation technology (e.g. ProCAST) it is possible to predict defects in castings and to reduce them by optimizing process parameters.

- This approach allows simulations to be carried out prior to actual production, thus saving time and costs.

Improvement of materials and process parameters

- Selection of suitable materials and adjustment of process parameters (e.g. pouring temperature, pressure, etc.) are also important means to avoid defects.

- For example, lowering the pouring temperature and injection speed can reduce porosity and other internal defects.

Regular maintenance of equipment

- To ensure that the die casting equipment is in good working condition is also an important measure to avoid defects.

- Regular inspection and maintenance of equipment can reduce defects caused by equipment failure.

Adoption of advanced analysis tools

- The use of neural networks and other advanced analysis tools can help to quickly identify and solve problems in the die casting process.

- For example, a BP neural network combined with an expert system can effectively analyze the causes of defects and propose solutions.

Avoiding Defects Through Die and Process Optimization

Precise die design and stable process parameters are the first line of defense to avoid die casting defects. They directly control how the metal fills the cavity, solidifies, and finally forms.

- Die Preheating and Temperature Balance

- Gating, Overflow, and Cooling System Optimization

- Injection Profile and Intensification Pressure Control

Die Preheating and Temperature Balance

Preheating the die to the required temperature (e.g., 150-250°C for aluminum) before production is essential to avoid filling defects like cold shuts. During continuous production, maintaining die thermal balance through multi-point temperature monitoring and dynamic cooling control prevents defects like porosity or hot cracks caused by local overheating or overcooling.

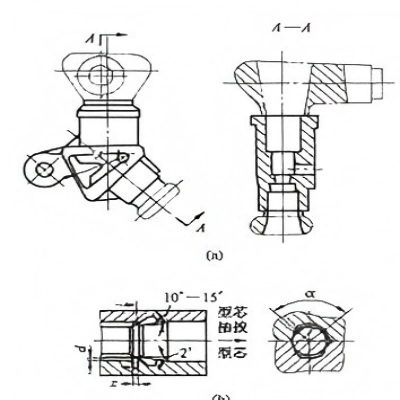

Gating, Overflow, and Cooling System Optimization

A well-designed gating and overflow system guides smooth, sequential metal flow and traps cold metal and gas in the overflows. Combined with balanced cooling channels, it controls the solidification direction, effectively helping to avoid die casting defects like shrinkage and porosity.

Injection Profile and Intensification Pressure Control

Setting multi-stage injection speeds ensures optimal metal flow to fill the cavity. Applying a high, stable intensification pressure at the right moment is core to compensating for solidification shrinkage and obtaining dense castings, which is fundamental to avoid die casting defects.

Strengthening Raw Material Management and Equipment Maintenance

Stable raw material performance and reliable equipment condition are the fundamental guarantees to avoid die casting defects at the source.

- Alloy Melting and Refining

- Die Release Agent Selection and Spray Control

- Scheduled Maintenance of Machine and Peripherals

Alloy Melting and Refining

Use alloy ingots with qualified composition and strictly control melting temperature and time. Effective degassing and refining of the molten metal reduce hydrogen content and oxides. This is a key step to avoid die casting defects like gas holes and inclusions at the material source.

Die Release Agent Selection and Spray Control

Choose a release agent suited to the product and die. Control its concentration, flow, and spray pattern with precise equipment. A uniform coating ensures easy part ejection and assists in local die cooling, preventing defects like sticking or cold shuts due to poor lubrication.

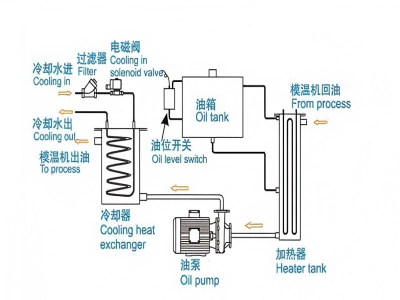

Scheduled Maintenance of Machine and Peripherals

Regularly check and calibrate the machine’s clamping force, injection speed, and pressure sensors to ensure accurate execution of process parameters. Also, maintain furnaces, extractors, sprayers, and other peripherals to ensure stable operation of the entire cell, reducing defects caused by equipment variance.

Haichen die casting machine supplier

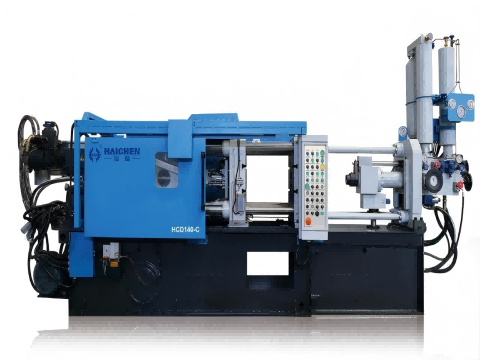

Haichen is a manufacturer of die casting machines, offering both hot chamber and cold chamber die casting machines.

Our die casting machines are designed for high quality, reliability, and efficiency, making them an excellent choice for a wide range of die casting applications.

Case: Solving Fill Issues for Complex Thin-Wall Parts

A customer producing laptop cases struggled with cold shuts and short shots due to complex, uneven wall design. Using a HAICHEN machine, its fast injection response and multi-stage (up to 10) injection profile settings allowed the metal to fill the farthest corners precisely as planned. Combined with stable intensification, part integrity improved greatly, reducing this defect rate from 5% to below 0.5%.

Systematically working to avoid die casting defects is an engineering task that requires coordination across dies, process, materials, equipment, and quality management. Every step is important, from fine die and process design to strict control of materials and equipment, and finally to intelligent process monitoring.