The die-casting machine tonnage usually refers to its clamping force. That is the maximum clamping force that the machine can provide during the die-casting process. This force needs to overcome the expansion force of molten metal in the mold cavity. And then to prevent metal splashing and ensure the quality of the casting.

To calculate the frying pan die casting machine tonnage, it is necessary to comprehensively consider the influence of die-casting process parameters like clamping force, die casting projection area, injection pressure ect. At the same time, it also need to consider with frying pan structural characteristics, mold design and so on.

The specific calculate die casting machine tonnage of die cast frying pan main factors and step are as following:

- Calculate projection area of the die casting

- Choose the right injection pressure

- Calculate the clamping force

- Consider the safety factor

- Precautions in practical applications

- Frying pan tonnage selection in practical application

Calculate projection area of the die casting

- Product area (A1)

- Pouring area (A2)

- Slag collection bag area (A3)

- Cake area (A4)

First, you need to know the projection area of the frying pan. The projection area includes the projection area of the product itself and the projection area of the gating system (such as gate, overflow trough, etc.). The casting area includes the total projected area of the following four parts:

Product area (A1)

The projected area of the frying pan (calculated based on the maximum contour).

Pouring area (A2)

usually 15% -30% of the product area.

Slag collection bag area (A3)

The area of the overflow groove and exhaust groove is approximately 10% -20% of the product area.

Cake area (A4)

determined by the diameter of the press chamber (punch)

Usually, the calculation formula for the projection area of the die casting is:

Projection area=product projection area+gate projection area+overflow trough projection area

Choose the right injection pressure

- Material properties

- Mold design

- Process parameters

- Equipment performance

The selection of injection pressure for die-casting machines is a complex process. It need consider about the structure of castings, material characteristics, mold design, process parameters, and equipment performance.

Material properties

The flowability, melting point, and thermal stability of different materials can affect the choice of injection pressure. Materials with poor fluidity or thin, long process plastic parts require higher injection pressure.

Mold design

The structure of the mold (such as pouring system, diversion channel, gate, etc.) also affects the selection of injection pressure. Reasonable mold design can reduce turbulence and porosity, thereby lowering the required injection pressure.

Process parameters

Injection speed, mold temperature, pouring temperature, and other process parameters are closely related to injection pressure. Usually, the faster the injection speed, the stronger the flow ability of the metal in the mold, and the fewer surface defects, but too high a speed may lead to porosity and cold insulation. Therefore, the injection pressure and speed should be matched to ensure the quality of the casting

Equipment performance

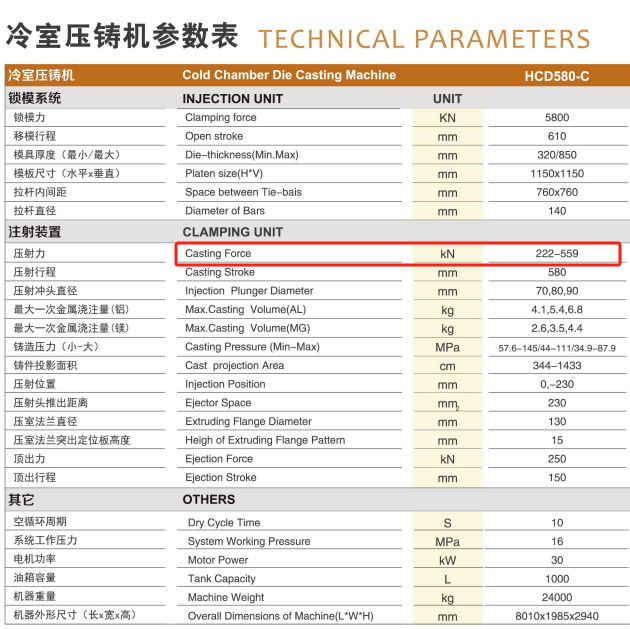

The selection of injection pressure should also consider the performance of the die-casting machine. For example, the injection pressure should generally be above 75% of the rated output of the die-casting machine, and the fluctuation range should be within 10% . At the same time, the injection pressure should be less than or equal to the nominal injection pressure of the die-casting machine, and a certain safety factor should be left.

Calculate the clamping force

The clamping force is the force used by the die casting machine to overcome the expansion force of the molten metal on the mold, ensuring that the mold is closed and preventing the molten metal from splashing. The calculation formula of clamping force is:

Clamping force = 1.4 × projected area × injection pressure

Among them, 1.4 is a coefficient used to compensate for the projected area of the pouring channel and slag well and increase the insurance factor.

Consider the safety factor

In order to ensure the safety of the production process and the quality of the castings, the clamping force usually needs to be 1.1 times greater than the mold opening force.

Clamping force>1.1×Mold opening force

Precautions in practical applications

- Safety factor

- Material selection

- Mold design

Safety factor

To ensure safety, it is usually recommended to set the locking force to at least 1.1 times the mold opening force to prevent splashing and dimensional deviation.

Material selection

Different materials (such as aluminum and zinc) have different requirements for casting pressure. Aluminum usually requires a tightness of over 80MPa, while zinc requires about 30MPa.

Mold design

Complex molds require greater locking force, so when choosing a die-casting machine, in addition to tonnage, the size, stroke, and feeding capacity of the mold also need to be considered.

Frying pan tonnage selection in practical application

HAICHEN Practice: Giving Accurate Calculation and Selection for Frying Pan Die Casting Machine Tonnage

HAICHEN gives not only machines but also expert analysis to ensure the chosen frying pan die casting machine tonnage is cost-effective and efficient.

Customer’s frying pan case

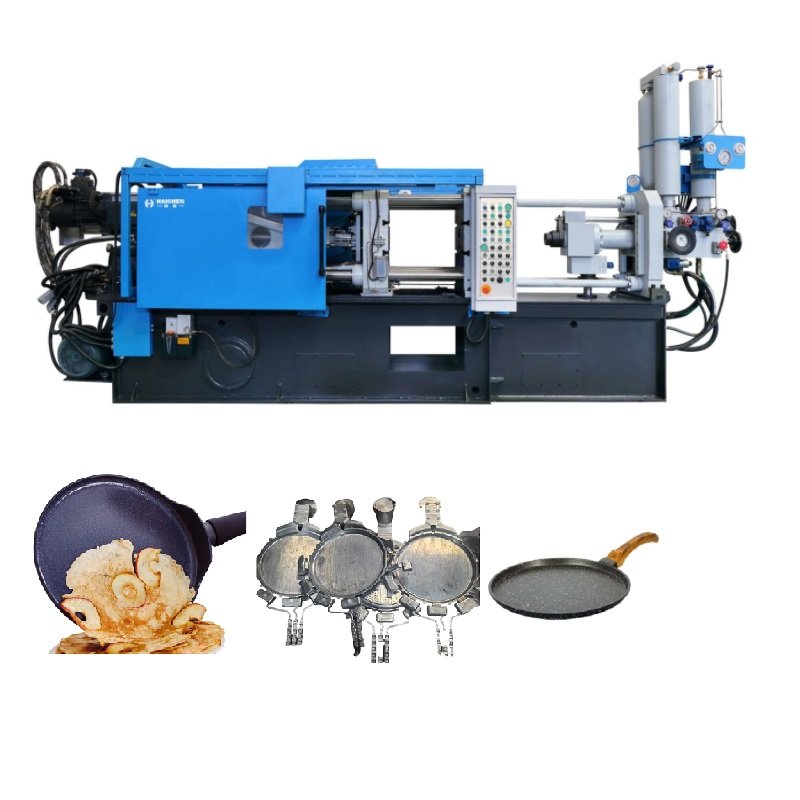

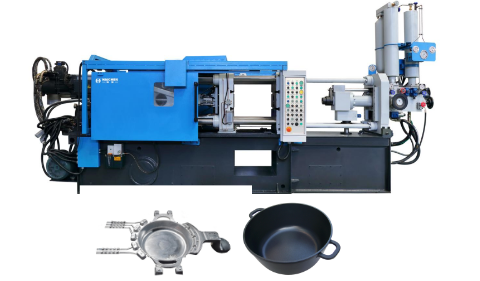

A cookware maker planned to make a range of aluminum frying pans in different sizes. They needed a new die casting machine but were unsure about the tonnage. They worried about low tonnage hurting quality and high tonnage wasting money.

HAICHEN’s Professional Analysis Service

HAICHEN engineers studied the mold design for the largest frying pan size. They calculated the total projected area including the runner system. Based on the surface and quality needs, they suggested a suitable injection pressure value.

Accurate Calculation and Plan Making

The customer agreed with the tonnage advice. After the machine started, the clamping force was enough. The frying pan castings had very little flash and stable sizes. The machine’s output and energy use reached a good balance. The return on investment met expectations, perfectly fitting the customer’s full production needs.

According to the above calculation results, select the appropriate die casting machine tonnage. In practical applications, it is necessary to verify through trial molding and dynamically adjust parameters based on product defects such as burrs and shrinkage holes.

For example, an ordinary flat-bottomed aluminum frying pan with a diameter of 20-28 cm requires around 680-ton die casting machine.

Through the above steps, we can calcuate the required tonnage of the die casting machine for casting frying pans more accurately. We need also consider factors in actual production such as mold design, material properties and production environment to ensure smooth production.

Haichen die casting machine

Haichen is one Chinese die casting machine manufactuer for more than 10years.We produce both high pressure cold chamber die casting machine and hot chamber die casting machine. These machines have durable and highly precise features. We also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

Haichen have rich experience to produce frying pans. As per each customer’s specifica demand, we can can supply production including frying pan die casting machine, frying pan moulds and auxiliary equipment.