Choose extractor in die casting includes application and model matching scope, technical performance and functionality, etc.

The extractor is the picking machine of a die casting machine. It is a mechanical device uses to automate the task of picking up die-casting parts. Its design and application are of great significance in improving production efficiency, reducing labor intensity, and enhancing safety.

When selecting a die-casting machine pick-up machine, it is necessary to comprehensively consider factors. Such as the tonnage of the die-casting equipment, production requirements, automation level, and budget, and choose the most suitable technical solution.

- Scope of application and model matching

- Technical performance and functionality

- Ease of operation and maintenance cost

- Safety and stability

- Economy

- Specific requirements and application scenarios

Scope of application and model matching

- Collect process data

- Divide requirements into hierarchies

- Reference the selection guide

- Establish an evaluation model

- Field Verification

- Final Matching

Select the appropriate picking machine based on the tonnage of the die casting machine.

For example, for small and medium-sized die-casting equipment (such as 50T-400T), it can select hot chamber die casting machine or servo spray type picking machine. For large equipment (such as 1000T and above), it can select servo robotic arms or multifunctional collaborative robots.

Collect process data

- Part drawings, weight, dimensions, materials, and production requirements.

- Workshop floor plan, ceiling height, and existing equipment interfaces (hydraulic, pneumatic, and communication protocols).

Divide requirements into hierarchies

- Required functions (such as core pulling, handling, and positioning).

- Optional functions (such as automatic die change, visual inspection, and energy consumption monitoring).

Reference the selection guide

Screen the appropriate extractor type (hydraulic, pneumatic, robotic, etc.) based on the number of stages, flow rate, separation characteristics, and site constraints.

Establish an evaluation model

- Assign a score to each candidate model (cost, footprint, energy consumption, compatibility, and automation).

- Use weighted summation or the Analytic Hierarchy Process (AHP) to determine a comprehensive score.

Field Verification

If possible, arrange on-site demonstrations or trial runs to verify key indicators. Such as actual thrust, positioning accuracy, and die change time.

Final Matching

Select the model with the highest overall score that meets all required functions. This is the optimal solution for model matching.

Technical performance and functionality

- Servo drive and accuracy

- Degree of automation

- Flexibility and scalability

Servo drive and accuracy

Servo picking machines have the characteristics of high precision and fast response. It is suitable for scenarios that require high repeatability positioning accuracy. Such as ± 0.02mm repeatability positioning accuracy.

Degree of automation

select whether to support linkage with die-casting machine, spray and other equipment to achieve fully automatic production. For example, servo manipulator can connect with die-casting machine and spray to improve production efficiency.

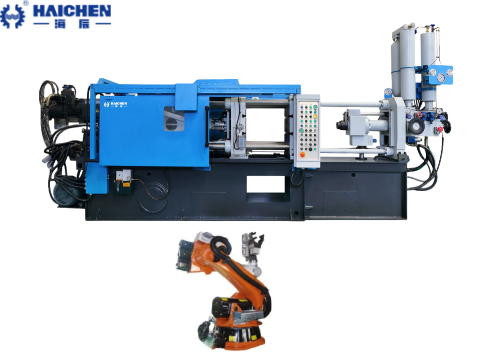

Haichen extractors provide critical automation advantages for die-casting process. Like they ensure consistent, high-speed part removal at the end of each cycle. Directly synchronizing with the machine’s operation. Using extractor can enhance workplace safety by removing personnel from the hazardous extraction zone and significantly improved production efficiency through reduced cycle times.

Their precise, programmable movement guarantees gentle handling of hot castings, minimizing part damage and deformation. This automation ensures a consistent, uninterrupted workflow, maximizes machine uptime, and is essential for achieving high-volume, high-quality production with optimal repeatability.

Flexibility and scalability

Robot picking machines usually have higher flexibility and can complete various operations. Such as deburring, slag removal, cooling, etc., making them suitable for multi process integrated production.

Ease of operation and maintenance cost

- Compatibility with Machine Tool Control Systems

- Level of Automation and Drive Method

- Structural Design and Maintenance Ease

- Maintenance Cost Structure and Assessment Methodology

For small and medium-sized die-casting enterprises with low requirements for operational skills. They can choose picking machines that are easy to operate and maintain.

Although the initial investment of robotic picking machines is relatively high, the long-term maintenance cost is relatively low. And they can completely replace manual labor to complete complex tasks.

Compatibility with Machine Tool Control Systems

- Uniform Operation Interface: Preferred unloading devices can be controlled directly from the die-casting machine’s HMI/PLC. Operators only need to start, adjust, and monitor the unloading operation on the machine’s main interface, eliminating the need for additional manual or stand-alone panel operations.

- Real-Time Diagnosis and Alarms: A control system with fault code display and early warning prompts allows for quick problem location when an anomaly occurs, reducing downtime and maintenance effort.

Level of Automation and Drive Method

- Motor/Robot Drive: Unloading devices using motors or robotic grippers offer smooth and fast operation, enabling high-frequency “standby” cycles, significantly reducing the time required to unload each workpiece and thus lowering overall cycle costs.

- Automatic Lubrication System: Built-in automatic lubrication extends the life of the locking mechanism, reducing routine maintenance frequency and manual lubrication costs.

Structural Design and Maintenance Ease

- Modular and Easy Disassembly: Key components utilize a standardized, modular design. Maintenance requires quick disassembly and replacement of individual components, avoiding extensive disassembly and improving repair efficiency.

- High-quality materials: Hydraulic and electrical components from renowned brands (such as MITSUBISHI, OMRON, and HYDAC) are selected to ensure wear and corrosion resistance, reducing repair costs due to component failure.

- Fault diagnosis: The PLC control circuit records fault codes, helping maintenance personnel quickly locate the problem and avoid unnecessary work hours caused by blind troubleshooting.

Maintenance Cost Structure and Assessment Methodology

- Personnel and Labor Hours: Estimate the labor costs required for routine run-to-run maintenance based on machine operating time.

- Consumables and Hydraulic Fluid: While automatic lubrication systems can reduce the frequency of manual lubrication, regular lubricant changes are still required, and the cost should be factored into the annual maintenance budget.

- Spare Parts and Replacement Cycles: Using standardized, readily available spare parts can reduce inventory costs and procurement cycles.

- Total Cost of Ownership (TCO): Compare these costs with the expected lifespan of the equipment and the benefits of increased production capacity to determine the actual maintenance cost per year or per unit.

Safety and stability

- Safety Feature Refinement

- Stability Enhancements

The picking machine should have good structural design and stability to adapt to harsh working environments. For example, servo picking machines typically use high-precision servo motors and sturdy and durable robotic arms.

High protection level robotic picking machines can effectively avoid product damage caused by mold opening errors in die-casting machines.

Safety Feature Refinement

- Interlocked Guard Door: The extractor must detect whether the safety door is closed before movement, automatically stopping or retracting if not.

- Emergency Stop and Safety Circuit: Equipped with an independent emergency stop circuit and dual safety circuits, the machine immediately shuts down in any abnormal situation.

- Guardrails/Guards: Fixed or movable guards are installed above or to the sides of the extractor to prevent hands or tools from entering.

Stability Enhancements

- Rigid Structural Design: A frame constructed of high-strength alloy or heat-treated steel is used to ensure no deformation during high-pressure injection and rapid extraction.

- Vibration Damping and Cushioning: Elastic gaskets or hydraulic buffer cylinders are installed between the extractor and the machine body to reduce the transmission of shock waves to the machine body.

Economy

For small and medium-sized enterprises and die-casting enterprises that do not produce products with inserts, they can choose lower priced picking machines to achieve automated production.

If the product requires high quality or requires the installation of inserts, it recommends to choose a high-end robot picking machine.

Specific requirements and application scenarios

If it is necessary to handle castings with a large weight (such as 4kg or more), a picking machine with strong load-bearing capacity should be selected.

For enterprises that need to quickly improve production efficiency, they can choose a picking machine with arm forward waiting function to accelerate the picking speed and increase the daily output of finished products.

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.