Cleaning up hydraulic oil in die casting machines is essential for maintaining a safe and efficient working environment.

Steps to clean up hydraulic oil in die casting machines

In the die casting machine hydraulic oil cleaning and maintenance process, need to take a series of measures to ensure the normal operation of the hydraulic system and extend the life of the equipment. The following are the detailed operation steps and precautions:

Preparation

Ensure Safety:

Put on protective gear such as gloves, safety goggles, and non-slip shoes. This protects you from potential hazards during the cleanup process.

Shut Down the Machine:

Turn off the die casting machine and lock it out to prevent accidental start-up. This is crucial for your safety.

Gather Supplies:

Collect absorbent materials like rags, paper towels, or specialized oil-absorbing pads. You will also need a container to collect the hydraulic oil, cleaning agents suitable for it, and a mop.

Initial Cleanup

Contain the Spill:

If the oil spill is still spreading, place absorbent pads or sand around the edges to stop it from spreading further.

Absorb the Oil:

Use absorbent materials to soak up as much oil as possible. Press the rags or pads firmly onto the spill to maximize absorption. Dispose of the used materials in a designated waste container.

Scrape Off Excess:

For large spills, use a scraper to remove any thick layers of oil. Be careful not to scratch the machine’s surface.

Detailed Cleaning

Apply Cleaning Agents:

Spray or pour a suitable cleaning agent onto the area where the hydraulic oil was spilled. Choose a cleaner that is effective for hydraulic oil and safe for the machine’s surface. Scrub the area vigorously with a brush or mop to break down any remaining oil residue.

Rinse Thoroughly:

After scrubbing, rinse the area with water to remove the cleaning agent and any remaining oil. Make sure to direct the water flow towards a drain or a container to avoid further contamination.

Dry the Surface:

Use clean rags or paper towels to dry the area completely. Ensure there is no moisture left, as it can cause rust or other issues.

Final Inspection

Check for Residue:

Inspect the cleaned area carefully to make sure there is no hydraulic oil residue left. Look for any stains or oily spots.

Verify Machine Integrity:

Check the machine for any damage caused by the spill. Ensure that all components are functioning properly before restarting the machine.

Dispose of Waste Properly:

Dispose of all used absorbent materials, rags, and contaminated water according to local regulations. Do not pour hydraulic oil down the drain as it can harm the environment.

Prevention

Regular Maintenance:

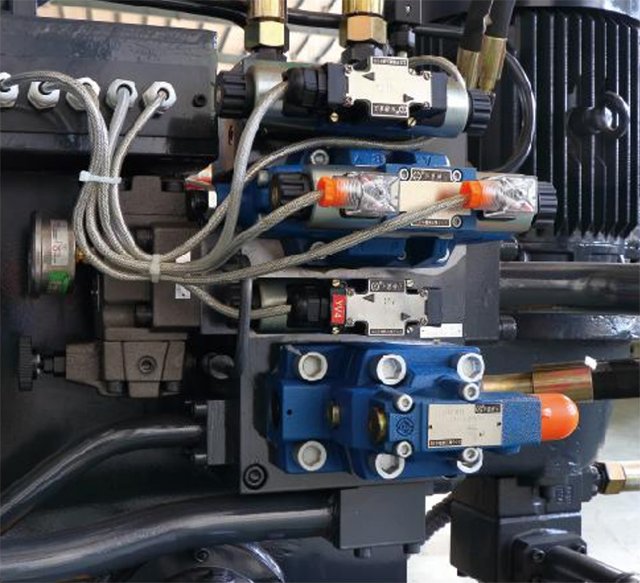

Regularly check the hydraulic system for leaks and wear. Replace any damaged seals or hoses promptly to prevent future spills.

Training:

Ensure that all operators are trained in proper machine operation and maintenance procedures to reduce the risk of hydraulic oil spills.

Safety Protocols:

Establish and enforce safety protocols for handling and cleaning up hydraulic oil spills. This includes having a designated spill response kit readily available.

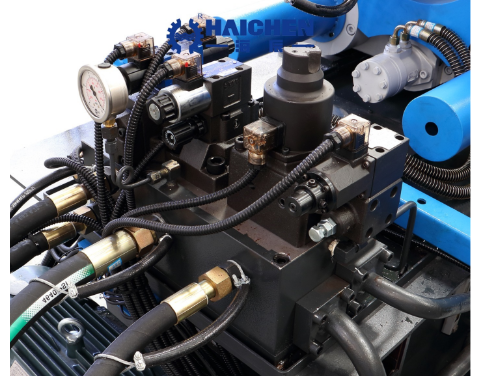

Die casting machine supplier: Haichen Machinery

Haichen Machinery is a supplier of die casting machines and other related equipment. We specialize in providing die casting production solutions for various materials, including aluminum, magnesium, zinc, and copper alloys. Our cold chamber and hot chamber die casting machines are used for manufacturing products such as automotive parts, LED lamp shells, radiators, and household appliance components.

By following these steps, you can effectively clean up hydraulic oil spills in die casting machines and maintain a safe and efficient workplace.