Improve die casting mold quality can be achieved through better selection of construction materials and their subsequent machining, use of high-precision tools, effective surface treatments, and maintaining accurate machining tolerances and regular inspections.

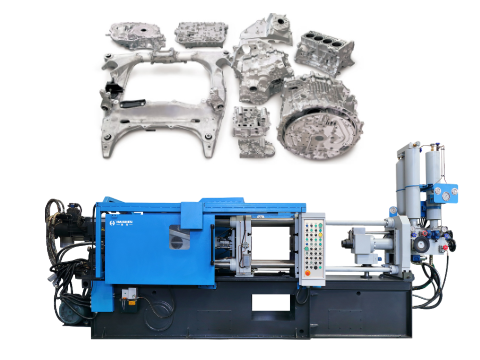

Die casting molds directly impact the quality, precision, and defect-free nature of the parts produced, thus, maintaining consistent quality across the production of critical components.

The accuracy and stability of a mold increases the precision and durability of the product thus enabling improved efficiency of production alongside a reduction in costs.

The remainder of this article details the strategies aimed to assist in the improvement of die casting mold quality, including design and material selection, cooling, maintenance, and the application of advanced simulation techniques. These processes greatly improve the mold quality and capabilities of production.

Precision in Mold Design

The core of precision die casting starts with accurate mold design. An accurately crafted mold guarantees smooth, complete, and uniform filling and solidification of molten metal. The following factors are important for mold design:

- Cavity Design: The mold cavity must represent the final part dimensions and consider shrinkage and tolerances.

- Venting: Adequate venting enables gas escape during injection, preventing gas porosity while enhancing surface finish.

- Draft Angles: Added draft angles helps in the smooth removal of the part from the mold without damage.

- Parting Lines: Parting line thickness should be as minimal as possible to reduce flash while maintaining surface cleanliness of the parts.

HAICHEN, the die casting machine manufacturer, provides advanced technologies and ensures mold design and manufacturing to be of the highest standards. The precision control systems incorporated in the machines enhance the accuracy and repeatability of the die casting process.

Material Selection for Mold Construction

Durability and performance molds is critical to the choice of performance. A good quality mold material is capable of withstanding the pressures and high temperatures of the die casting process. It is also essential to maintain a proper mold dimensional stability over time. Withstand the pressures and temperatures of the casting process are of primary concern. Key considerations include:

- Tool Steel: As to the concern of the performance attributes of the mold, tool Steel A-grade tool steel is preferred, as it is of high-grade and most beneficial to the mold due to its hardness, wear resistance, and ability to the resist thermal cycling.

- Surface Treatments: Surface Treatments Improvement of the wear resistance of the mold is also possible with the application of surface treatments such as nitriding or application of coating.

- Heat Treatment: Heat Treating Proper thermal treatments of a die casting mold is also critical as it makes sure of the proper values of hardness and toughness is attained, which helps the mold to withstand high tmeperature without cracking.

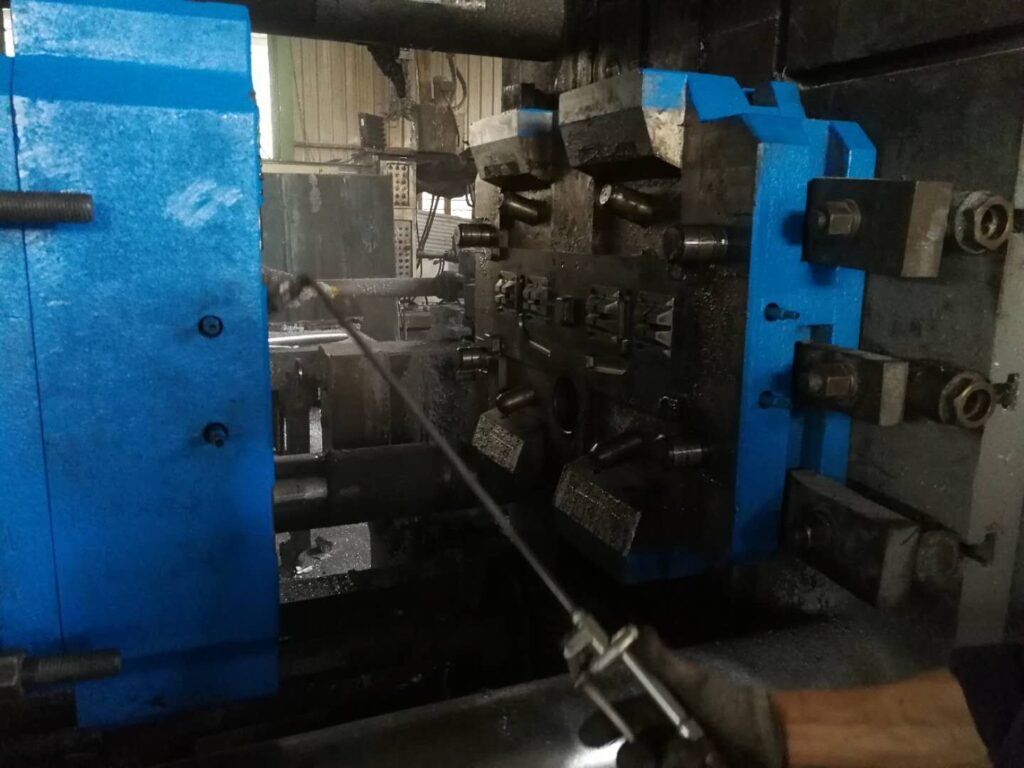

Maintenance and Inspection

Maintaining mold quality also include a routine and inspections. Well maintained molds are crucial to the reduction of defects and further down the operational life. Key practices include:

- Regular Cleaning: Cleaning Regular metal and debris removal ensures proper operational cycles of the mold.

- Lubrication: Ventilation Allowing mold release agents to ensure smooth ejection of parts prevents sticking to the molds.

- Inspection: Inspection Regular mold inspections ensure mold issues such as wear, damage and erosion is dealt with promptly to prevent further damage.

- Storage: Storage Protecting molds from environmental factors such as rust and damage while not in use ensures proper rotation and the lifecycle of the molds.

Process Control and Optimization

Enhancing the parameters of the die casting process is critical for maintaining the quality of the die and mold. Some crucial factors are as follows:

- Injection Speed: Modify the injection speed to optimally fill the mold cavity without turbulence or defects.

- Temperature Control: Keep mold and metal temperatures constant to avoid thermal gradients and solidification shrinkage anisotropy which induces thermal stress.

- Cycle Time: Balance production efficiency and mold life in maximizing mold cycle time.

The advanced die casting machines produced by HAICHEN are equipped with advanced control systems which enable real time monitoring and adjustment of process parameters. Such systems help in maintaining consistency of quality and minimizing mold damages.

Collaboration with Experienced Mold Makers

Working with skilled mold makers remains very essential in achieving high precision molds. Die casting mold makers are more beneficial to mold design because of their experience in material selection and mold maintenance. HAICHEN works with the best mold makers to ensure their customers receive the best options and services.

Practical Experience at HAICHEN

HAICHEN has extensive experience in optimizing mold quality for various applications. For example, in the production of aluminum pots, road studs, and medals, HAICHEN’s machines are equipped with advanced features that ensure high – quality mold performance. Our machines are designed to handle the high pressures and temperatures involved in the die – casting process, ensuring consistent and high – quality production.

Improving die casting mold quality features precise design and selection of materials, scheduled maintenance, and process control. Enhanced mold quality improves the performance of the parts and reduces long-term costs and downtimes.