To install die casting mold, first ensure the mold is clean and free of debris, then carefully align and secure the mold halves onto the die casting machine’s platens, making sure they are properly seated and clamped to prevent leaks and ensure uniform part quality.

Installing molds used for die casting requires accuracy and focus for maximum part quality. This step also determines the ultimate outcome of the die casting process.

In order to achieve production that is of high quality and consistent, one must understand the importance of properly installing the die casting molds.

In this text, we will focus on best methods to approach installation of a die casting mold and take into consideration the crucial steps that uphold best practices.

We will analyze the benefits that proper installation of die casting molds has on production effectiveness, the quality of the produced part, and the overall functionality of the machine.

Pre-Installation Preparations

- Check Mold and Equipment Compatibility

- Confirm Mold Condition

- Die-casting Machine and Site Preparation

Check Mold and Equipment Compatibility

- The surface area of the mold ought to meet the requirements of the ‘machine die casting’. Its total height should exceed the minimum die opening distance and the the mold height plus the die opening stroke must be within the maximum die opening distance in order avoid interference.

- The alignment of the mold positioning holes and lifting holes and the die casting machin interface and the mold for the ejector pin position and profiles must the match the equipment.

- The sprue bushing and die casting machine nozzle alignment must be confirmed die casting machine must be aligned with the die casting chamber.

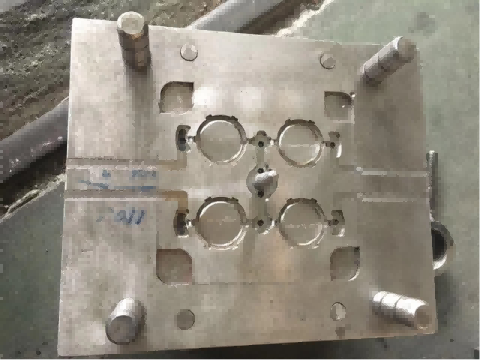

Confirm Mold Condition

- The surface plastic of the mold should be plain for the mounting surface. Missing oil and dirt and large scratches, rust, and cracks should be removed first.

- The movement of parts should be tested the guide pins and bushes, the ejector pin, and the slideways should be smoothly activated trigger.

- Also, the cooling water channels must be checked for blockage and leaks.

Die-casting Machine and Site Preparation

- The ejector should be in position, equipment with the hydraulic and electrical systems operating correctly plus movement being smooth , and devices within the set up.

- Site Requirements: The ground must be level (recommended C30 concrete thickness ≥ 400mm). And the load-bearing capacity must be sufficient for the mold weight.

- Tools required: Lifting equipment (hook/wire rope strength meeting standards), pressure plates, high-strength bolts, cooling water pipes, etc.

Installing die casting mold

- Preparation

- Alignment

- Securing the Mold

- Testing

- Lubrication

- Safety Checks

Preparation

Before proceeding to the installation, check that both the mold and the diecasting machine are detached from one another and devoid of any leftover particles. Look for any abnormalities on the surface of the casting mold, that is, whether it is chipped a scratched. Above all, ensure that all the compartment and cavitation cavities sparked from the previous casting cycles have all been cleaned.

Alignment

The next phase is to position the mold on the die casting machine. Make sure that both the seating and alignment of the hive are correct with the machine securing unit. For precise position alignment use alignment pins. Guides are helpful, but more is more when it comes to alignment with diecasting. Failure to align the mold properly will result in the wrong casting and therefore, lower the quality of the product.

Securing the Mold

At that point, securely lock the mold onto the machine using suitable diecasting fasteners. It is of importance that the mold is held and all the fasteners are tensioned according to the specified values from the manufacturer. Wrong tension maneuvers will result in a loss of cured molds and. Poor parts will also be made, therefore to keep the integrity no imbalance during diecasting cycle should happen.

Testing

To check that there are no diecasting defects, check for any pressures on the molds, which could induce leakage. Failure to follow the requirements of casted parts will result in faults which dismantle the die casting machine.

Lubrication

Apply lubricant to all movable components of the mold and the components of the die casting machine to pavat friction and wear. Ensure all moving parts are operational to achieve the desired degree of wear and effectiveness of both the mold and the machine.

Safety Checks

And the rest of the safety protocol starting from anytime the mold attachments and changes are done. Ensure the switch for the machine is both off and locked so it can’t be used by mistake. Put on the necessary the necessary personal protective gears to shield yourself from the visible and invisible dangers.

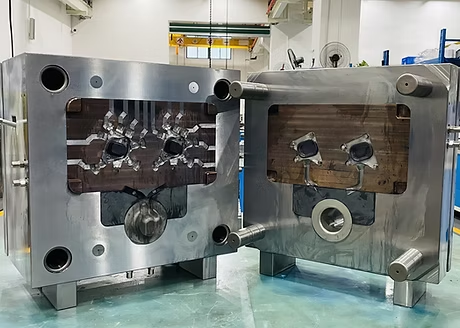

HAICHEN Mold Installation Technical Support Example

HAICHEN provides precise technical support during mold installation to ensure efficient integration with our machines. We use the installation of a mold for a 280mm aluminum fry pan on a 650-ton machine as an example.

- Precise Alignment & Quick Setup: This deep-cavity, thin-wall mold needed very exact alignment. HAICHEN engineers first guided the use of the machine’s high-precision positioning system. After mold closing, they used a laser sensor to check the parallelism of the parting surface, adjusting the error to under 0.05mm.

- Systematic Parameter Presets: After installation, our team loaded a standard process parameter package (including injection speed, pressure profile, mold temperatures) for this part into the machine control. This greatly reduced later process tuning time.

- Result: With this guided installation and parameter preset, the time from mold setup to producing a stable first good part was cut by about 40%. It also ensured consistent clamping accuracy and cycle time in later mass production.

HAICHEN: Die Casting Machine Manufacturer

HAICHEN manufactures both types of die casting machines, cold and hot chamber machines, that are tailored to separate production needs. We also offers technical assistance, spare part provision. And then training as part of on a complete service after a purchase to maximize the economic result gained.

To operate optimally and generate die cast parts of high quality, several conditions must be satisfied: optimal installation of the die casting machine molds and proper alignment of the machine forming the die molds as one piece.