Selecting the right accumulator for your die casting machine ensures consistent performance, reduces downtime, and improves efficiency.

Steps to select accumulator in die casting

Selecting the right accumulator for die casting is crucial for ensuring efficient and reliable production. Here are some key steps and considerations to help you make the right choice:

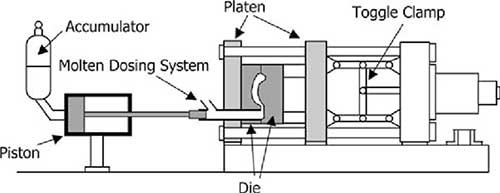

Understand the Role of Accumulators in Die Casting

Accumulators are used in die casting machines to provide rapid, high-pressure injection of molten metal into the mold. They store hydraulic fluid under pressure and release it quickly when needed, ensuring consistent casting quality and reducing cycle times.

Choose the Right Type of Accumulator

There are two main types of accumulators: gas-charged accumulators and piston accumulators. Gas-charged accumulators use a flexible bladder to separate the gas and hydraulic fluid, while piston accumulators use a movable piston. Piston accumulators are more common in die casting due to their higher strength and reliability. They are suitable for large volume and high flow systems and can operate in a wide temperature range.

Consider the Operating Conditions

Pressure Requirements: Ensure the accumulator can handle the maximum operating pressure required for your die casting process, typically between 200 and 300 bar.

Temperature Range: The accumulator should be able to operate within the temperature range of your production environment. Ambient temperatures can affect the pressure inside the accumulator, so it is important to account for these variations.

Cycle Time: The accumulator must be able to recharge quickly between cycles to maintain a high production rate.

Evaluate Additional Features

Cavitation and Pressure Peaks: Some accumulators are designed to reduce cavitation and pressure peaks, which can improve the longevity of the hydraulic system.

Mounting Orientation: Ensure the accumulator can be mounted in the required orientation for your machine.

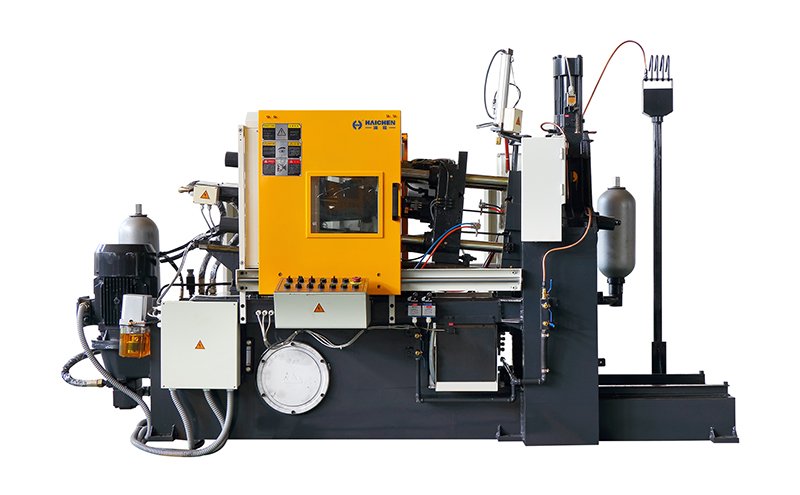

Die casting machine supplier: Haichen Machinery

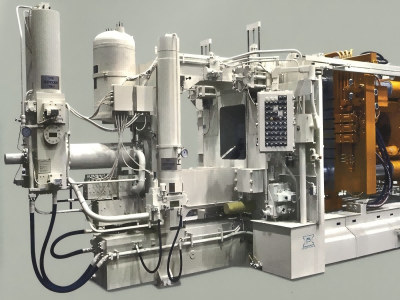

Haichen Machinery is a well-known supplier of die casting machines, specializing in the design, manufacturing, and service of high-pressure die casting (HPDC) equipment. The company provides a range of die casting solutions for industries such as automotive, electronics, home appliances, and more.

Key Features of Haichen Machinery Die Casting Machines:

Wide Range of Models:

Offers cold chamber die casting machines and hot chamber die casting machines.

High Precision & Efficiency:

Advanced hydraulic and control systems ensure stable performance and high productivity.

Energy-Saving Technology:

Some models feature servo-driven systems to reduce power consumption.

Reliability & Durability:

Robust construction with high-quality components for long service life.

Automation Compatibility:

Supports integration with robotic arms and smart factory systems