Select ladle in die casting includes material selection, size and shape, operation mode, process requirements, etc.

When choosing a ladle for die casting, you need to consider factors such as material properties, size and shape, operation method, process requirements, equipment compatibility, and maintenance life. By making a reasonable choice, you can effectively improve the quality and efficiency of the die casting process.

To choose a ladle for die casting, you need to consider multiple factors, including material properties, operation methods, process requirements, and equipment compatibility.

Material selection

The ladle is usually made of high temperature resistant materials. Such as cast iron, cast steel or heat-resistant steel, which can withstand the impact of high temperature molten metal and reduce heat loss.

In addition, the surface of the ladle usually need to coat with a refractory coating to prevent erosion. And moreover, adhesion of molten metal and ensure a longer service life.

Malleable Iron

- Feature: Low cost, moderate strength, average wear resistance

- Applicable alloys/process: Zinc, lead, low melting point alloy (hot chamber)

Alloy steel (such as H11, H13)

- Feature: Good high temperature strength, strong thermal fatigue resistance, and impact resistance

- Applicable alloys/process: Aluminum, magnesium alloy (cold room)

Stainless steel (304/316)

- Feature: Corrosion-resistant and high-temperature-resistant (≤800°C)

- Applicable alloy/process: Special alloys for metals sensitive to corrosion

Size and Shape

The size and shape of the ladle should select according to the needs of the die casting process.

For example, in the die casting of light alloys such as aluminum and magnesium. The ladle needs to be able to smoothly pour the molten metal into the chamber of the cold chamber die casting machine.

The opening design of the ladle is also important. And a wide mouth should use to facilitate the smooth scooping of the molten metal.

Size selection principles

Determine the scoop cup capacity based on the shot weight

The scoop cup capacity should not exceed 10% of the actual pouring weight to minimize heat loss and metal temperature fluctuations. A common empirical formula is:

Scoop cup capacity ≈ shot weight × 1.1 (unit: kg)

Avoid using spoons and cups that are too large

A spoon cup that is too large will cause the metal to stay in the spoon longer, causing heat loss and temperature drop, which in turn increases the risk of defects.

Consider pouring speed and spoon advance time

By optimizing the ladle forwarding time and tilt angle, the metal can enter the mold in the shortest time possible, maintaining a laminar flow state.

Shape selection principles

Cylindrical

The cylindrical shape is the most common spoon body shape in the industry. It has a simple structure and uniform force, and is suitable for most high-pressure die-casting machines.

Rectangular sleeve

In experimental research, rectangular troughs (e.g., 300 × 60 × 35 mm) are often used with tilted spoons to directly observe metal flow behavior.

This shape is primarily used for process development and flow visualization, rather than for routine production line use.

Conical/chamfered bottom

In order to reduce the retention of metal at the bottom of the spoon, the bottom of the spoon is often designed with a cone or chamfer to make it easier for the metal to flow out smoothly.

Tilt angle

By adjusting the tilt angle between the scoop and the mold, the metal flow rate and impact force can be controlled. The variable tilt angle in the experimental setup is used to optimize the pouring process.

Operation mode

The ladle can manually operate or automate.

In automated die casting

The ladle usually mount on a robot or die casting manipulator to achieve efficient and stable metal flow.

- Manual valve or pedal control

- Simple tilt mechanism

- Low cost and easy maintenance

In manual die casting

The handle of the ladle needs to be long enough to allow the operator to safely stay away from the hot metal.

- MANUALTEACH and AUTOTEACH modes

- Keyboard displays real-time position and status

- Receives START and STOP signals from the PLC

Process requirements

In aluminum die casting, special attention should pay to the use of the ladle to avoid oxide film or slag mixing into the molten metal.

Therefore, when taking the material, it is necessary to carefully remove the oxide film or slag layer on the surface. And ensure that the surface of the molten metal in the ladle is flat.

The ladle must meet your specific production needs.

Metal Type and Temperature

Different metals need different ladles. For example, aluminum and zinc have different melting points. The ladle material must handle the right temperature without damage.

Ladle Capacity and Weight

Choose a size that matches your shot weight. A small ladle needs many refills, which slows work. A very large ladle is heavy and hard to control. The right size improves efficiency.

Pouring Speed and Control

The ladle design affects how you pour. A good spout gives a smooth, controlled flow. This helps fill the mold properly and reduces splashes.

In addition, the ladle need to preheat before using, and the coating should regularly renew during use to prevent contamination.

Therefore, the design and specifications of the ladle need to match the production capacity of the equipment.

Maintenance and lifespan

The service life of a ladle is closely related to its material and maintenance.

For example, in some processes, the use time of the ladle need to control within a certain range (such as 150 hours) to avoid performance degradation due to long-term use.

At the same time, regular inspection and replacement of the refractory coating is also an important measure to extend the life of the ladle.

Safety and efficiency

The design of the ladle must ensure the safety of operation, such as protecting the operator through reasonable handle length and heat insulation.

In addition, efficient ladle design can reduce waste during metal flow and improve production efficiency.

HAICHEN’s Practical Experience and Solutions

HAICHEN helps customers choose the right tools for better results.

- Case Study: Aluminum Auto Part Production: A customer made engine parts. They used a small, uncoated steel ladle. Metal often stuck inside, and temperature dropped too fast. We suggested a ceramic-coated ladle with better insulation. This kept the metal hot longer and improved casting quality.

- Case Study: Zinc Alloy Hardware: Another customer cast zinc handles. Their old ladle was heavy and caused fatigue. We provided a lighter, balanced ladle with a heat-resistant handle. Workers could pour more easily and safely. Productivity increased by 15%.

- HAICHEN’s Support for Customers: As a die casting machine maker, we know good tools matter. We offer advice on ladle selection and other accessories. Our goal is to help you build a smooth, efficient production line.

Choosing the right ladle requires attention to process needs, material, and safety. Consider the metal type, ladle size, and pouring control. Also, pick a durable, safe design for long-term use. HAICHEN experience shows that the proper ladle can solve problems and boost efficiency. With the right tools and knowledge, you can achieve safer and more productive die casting operations.

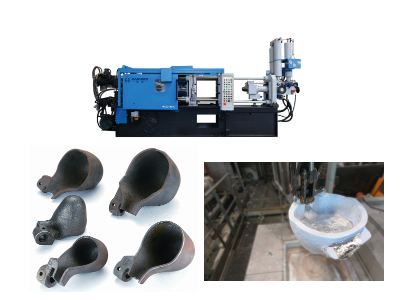

Haichen die casting machine

Haichen is one Chinese die casting machine manufacturer for more than 10years. We produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.