Using 3D printing to make molds for metal casting is a modern and efficient approach that combines the flexibility of additive manufacturing with the strength and durability of metal casting.

This process is particularly useful for prototyping, custom parts, or low-volume production. Below is a step-by-step guide on how to use 3D printing to make molds for metal casting.

Steps to use 3D printing to make moulds for metal casting

Choose the Right 3D Printing Technology

- Fused Deposition Modeling (FDM): Uses thermoplastic filaments like PLA or ABS. Suitable for simple patterns or low-temperature casting.

- Stereolithography (SLA): Uses resin to create high-detail patterns. Ideal for intricate designs.

- Selective Laser Sintering (SLS): Uses nylon or other powders to create durable patterns.

- Binder Jetting: Can print sand molds directly for sand casting.

- Best for Metal Casting: SLA or SLS for detailed patterns, or binder jetting for direct sand mold printing.

Design the 3D Model

- Use CAD software (e.g., SolidWorks, Fusion 360, or Blender) to design the part you want to cast.

- Include draft angles and shrinkage allowances to account for metal cooling and contraction.

- If creating a pattern for sand casting, design the pattern with sprue, gates, and risers for proper metal flow.

3D Print the Pattern or Mold

- For Lost-Wax Casting (Investment Casting): Print the pattern using wax-like resin (SLA) or a burnable material. And the printed pattern will be used to create a ceramic shell mold.

- For Sand Casting: Print the pattern directly using a durable material (e.g., PLA or resin). Alternatively, use binder jetting to print the sand mold directly.

- For Direct Mold Printing: Print the mold cavity directly using a high-temperature-resistant material (e.g., ceramic or sand)

Prepare the Mold for Casting

- For Lost-Wax Casting:

Attach the 3D-printed pattern to a wax tree.

Dip the tree in ceramic slurry and coat it with sand to build a shell.

Burn out the 3D-printed pattern in a kiln, leaving a hollow ceramic mold.

- For Sand Casting:

Place the 3D-printed pattern in a flask and pack it with sand.

Remove the pattern to leave a cavity in the sand.

Alternatively, use a 3D-printed sand mold directly.

- For Direct Mold Printing:

Use the 3D-printed mold as-is, ensuring it can withstand the temperature of the molten metal.

Cast the Metal

- Melt the metal (e.g., aluminum, bronze, or steel) in a furnace.

- Pour the molten metal into the mold cavity.

- Allow the metal to cool and solidify.

Finish the Cast Part

- Remove the mold (break away the sand or ceramic shell).

- Cut off any excess material (e.g., sprues or gates).

- Clean, polish, or machine the part as needed.

Precautions of using 3D printing to make moulds for metal casting

Material selection: Choosing the right 3D printing material is critical, especially for high temperature casting applications.

Post-processing: Ensure the surface quality of the mold and casting to improve the accuracy and durability of the final product.

Technical constraints: While 3D printing technology has great potential in the casting field, there are still some technical challenges that need to be addressed, such as the mechanical properties and thermal stability of the material.

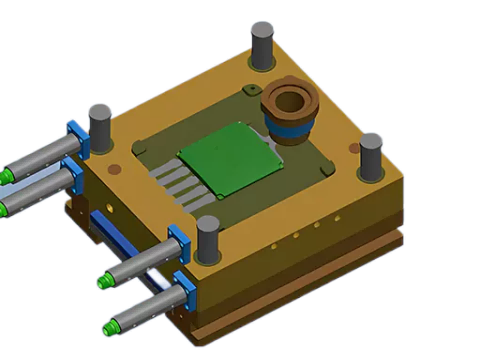

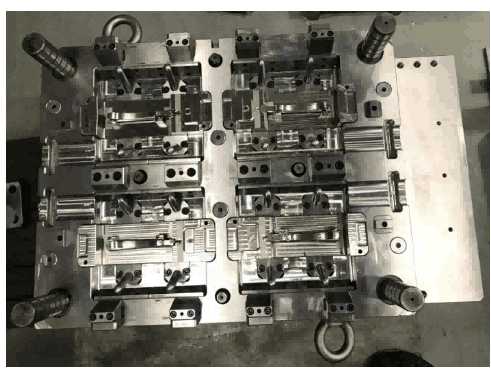

Haichen die casting mould design

Haichen is a well-known manufacturer of die-casting machines, and designing a die-casting mold (also called a die or tool) for use with Haichen machines requires careful planning and expertise. We mainly supply cold chamber and hot chamber die casting machines and aulixiary equipments. Die-casting molds are used to produce metal parts with high precision and repeatability, typically using materials like aluminum, zinc, or magnesium.

We can design a high-quality die-casting mold according to the customers’ needs.