Zinc aluminum die casting works by injecting molten zinc or aluminum alloy into the mold cavity at high pressure. It cools and solidifies into the high-precision parts with intricate details and tight tolerances.

A high-precision lightweight metal part is produce using zinc-aluminum die casting technology.

Parts produced using this method will possess the advantages of both zinc and aluminum alloys, making them strong and structurally durable.

In the automotive and aerospace industries, as well as consumer electronics, zinc aluminum die casting is use where high strength to weight ratio is required.

Definition and Core Principles of Zinc-Aluminum Die Casting

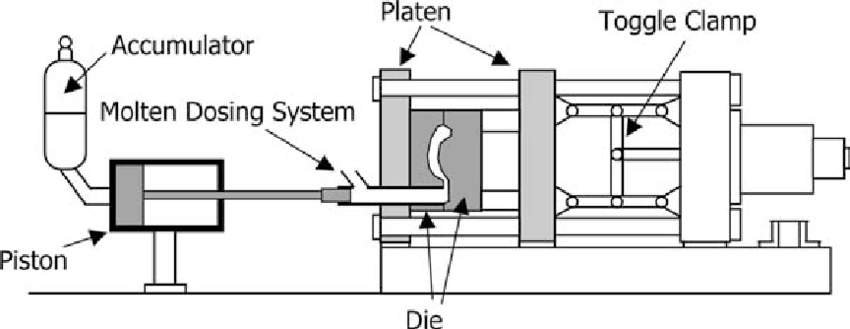

Aluminum Die Casting is a high-pressure precision casting technique. A zinc-aluminum alloy is heate until molten and is injecte at high speed and high-pressure (>10,000 psi) into a steel mold cavity using a dedicated die casting machine. After cooling, high precision parts undergo isothermal cooling and pressure forming. The core advantages is that it:

- Dimensional Accuracy: Tolerances of ±0.1mm is not uncommon, avoiding further processing.

- Microstructural Optimization: The filling of cavification of the mold with molten metal at high pressure and dynamic pressure forging eliminates not only volumetric but also structural material failures, producing as forged broken grains which greatly improves the mechanical properties.

- Efficient Mass Production: 10 second cycle times are achievable.

Key Steps in Zinc Aluminum Die Casting Works

- Material Preparation

- Mold Preparation

- Metal Injection

- Cooling and Solidification

- Ejection and Trimming

- Post-Processing

Material Preparation

The first step in zinc aluminum die casting is material preparation. The material options are zinc and aluminum alloys due to their high strength to weight ratio and corrosion resistance. The die casting process involves melting the alloys in a furnace at temperatures of 400°C to 600°C for Zinc and 660°C to 700°C for aluminum.

Mold Preparation

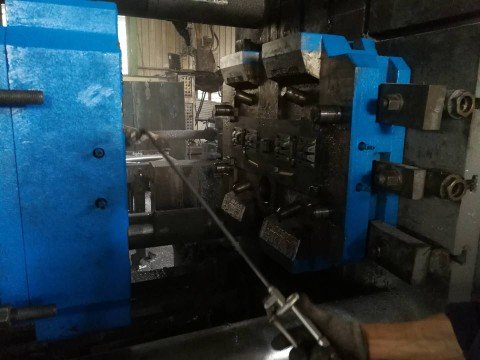

To prepare the mold, it is thoroughly clean and lubricate to ensure the smooth release of the cast part. The mold is normally create from A-2 or D-2 high grade alloy steel. The mold is covere in two parts which is the cover die and the ejector. These parts are locke and aligne together to create the cavity which will shape the final part.

Metal Injection

Transfer the alloy into the injection chamber of the die casting machine. Under high pressure the molten metal is injecte into the mold cavity to up to speeds of 100m/s. This injection of metal at high rates ensures the metal fills the cavity completely and forms the desired final shape.

Cooling and Solidification

After injecting the mold, the cooled metal starts to solidify. The mold is designe in a way to make the metal solidify in just a few seconds. Effective cooling is required to avoid shrinkage and porosity. In some instances we add cooling channels to the mold to expedite cooling.

Ejection and Trimming

Once the metal has cooled and solidified, we commence the breakdown of the mold by parting the mold halves and removing the cast piece with the help of ejector pins. The piece may still be connecte to runners and gates, which are the channels that allowed the molten metal to flow. We trim these excess piece either manually, or with the help of machinery, to reveal the final part.

Post-Processing

In zinc aluminum die casting, the final operation is post-processing. This includes finishing operations such as grinding, polishing, or painting, which are aim at improving the surface and durability of the part. Some parts may be heat treated to enhance mechanical properties as well.

Advantages of Zinc Aluminum Die Casting Works

- Lightweight and High Strength

- Precision and Complexity

- High Production Efficiency

Lightweight and High Strength

Zinc aluminum die cast components are light in weight and strong in nature which makes them perfect for use in the automotive and aerospace industries where weight reduction is necessary.

Precision and Complexity

The zinc aluminum die casting process is capable of offering high accuracy and ability to create complex geometries, which means manufacturers are able to make parts that are sophisticated as well as precision components.

High Production Efficiency

The die casting is capable of carrying out thousands of components in a span of hours faster. The die casting procedure is a quick one, hence is especially useful and efficient for large scale production.

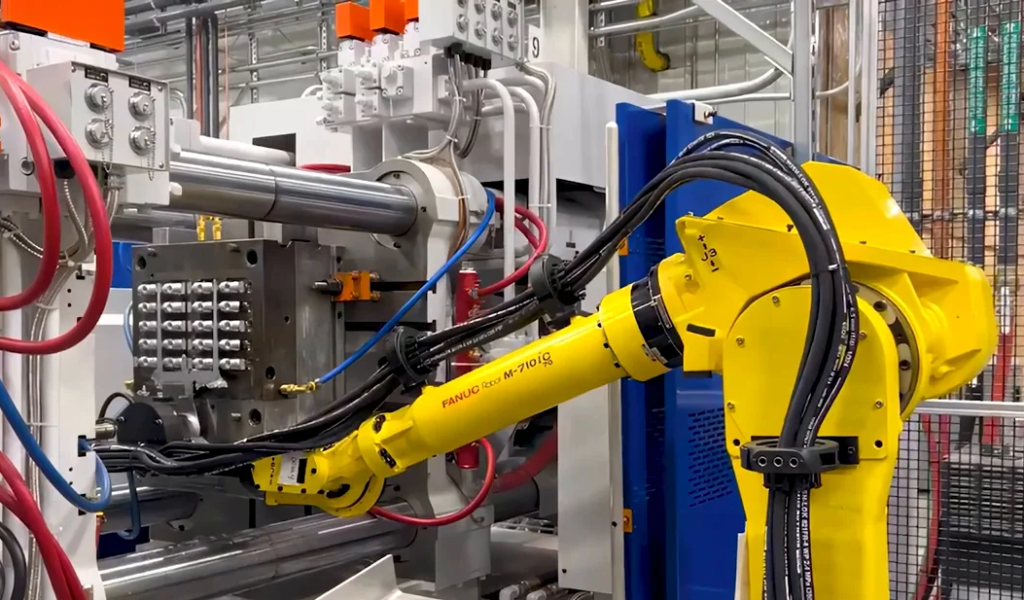

HAICHEN: Die Casting Machine Manufacturer

For die casting machines, HAICHEN is one of the most respected manufacturers. Their machines have pioneering technology and can endure industrial wear and tear. With them, the consumers are assured of quality and reliability.

Our company is the casting machines manufacturers offering cold chamber and hot chamber die casting machines and fulfilling both small and large scale production requirements. With HAICHEN, consumers get the best value for their money as he provides comprehensive after sales service and support.

HAICHEN Zinc-Aluminum Alloy Die Casting Application Example

HAICHEN die casting machines use targeted process control to leverage the strengths of both zinc and aluminum alloys. For example, in producing a complex zinc alloy smart lock housing with high surface finish requirements, we used a hot chamber machine.

Precise furnace temperature control (415±5℃) and injection profile ensured fast filling while avoiding flow marks and cold shuts. For an aluminum auto bracket, we used a cold chamber machine, optimizing high-speed switch points and intensification pressure to achieve strength with weight reduction.

HAICHEN’s solutions helped both product lines achieve stable yield rates over 99%, significantly improving our customer’s production efficiency and product competitiveness.

Most die casting Zinc-aluminum alloy are light and high in strength. Understanding the process of die casting is very important in the process of high quality metal parts.