Die Casting Machine Maintenance is vital to ensure its efficient and reliable operation.It is a necessary management tool to ensure the safe operation.

Maintenance of die casting machines is the key to ensuring their efficient, safe and sustainable operation.

By regularly checking, cleaning, lubricating and replacing parts, the life of the equipment can be extended, production efficiency and product quality can be improved, and production costs and safety hazards can be reduced.

This daily work is the necessary foundation for a factory

The effectiveness of die casting machine maintenance

The following is a detailed analysis of the importance of die casting machine maintenance:

- Increase equipment life and reduce downtime

- Ensure production efficiency and product quality

- Reduce operating costs

- Improve safety

- Extend mould life

- Adapt to modern production needs

Increase equipment life and reduce downtime

Regular maintenance can significantly extend the life of a die casting machine and reduce downtime due to equipment failure.

For example, by regularly inspecting and replacing worn parts, avoid small problems from evolving into big problems.

Thus reducing maintenance costs and downtime.

Ensure production efficiency and product quality

A well-maintained die casting machine can ensure production continuity and product quality.

By regularly checking the hydraulic system, lubrication system and mould components, you can ensure that the equipment is running in the best condition.

Thus improving production efficiency and casting quality.

Reduce operating costs

Maintenance helps to reduce equipment failures and unplanned downtime, thereby reducing repair costs and lost downtime.

For example, that the total downtime and maintenance costs of die casting machines can significantly cut down through preventive maintenance.

Improve safety

Proper maintenance procedures not only protect the equipment, but also safeguard the operator.

Regular inspection of safety devices and emergency stop buttons can prevent accidents.

Extend mould life

The mould is a key component in the die-casting process, and its wear and damage will directly affect product quality and productivity.

Through regular inspection and maintenance of the mould, you can extend its service life and reduce the frequency of replacement.

Adapt to modern production needs

With the development of Industry 4.0, intelligent monitoring and maintenance systems are becoming increasingly important.

Using machine learning and artificial intelligence technology for fault prediction and maintenance planning can further improve the reliability and efficiency of die casting machines.

Maintenance of die casting machines is essential to ensure normal operation of the equipment, improve productivity, reduce costs and ensure safety.

Enterprises should develop a scientific maintenance plan and strictly implement it to maximise the service life and economic benefits of the equipment.

Detail work of Die Casting Machine Maintenance

Die casting machine maintenance is the main work of the daily management of die casting machine machinery and equipment.

The content includes the following aspects:

- Daily maintenance and inspection

- Preventive Maintenance

- Die Casting Mould maintenance

- Operator training and safety procedures

- Data analysis and troubleshooting

- Equipment overhaul

- Cost control and economic efficiency

Daily maintenance and inspection

Die casting machines need to clean and lubricate on a regular basis to prevent wear and prolong equipment life.

This includes regular inspections of the various parts of the machine to detect any potential problems or signs of wear.

And timely replacement of worn parts.

Preventive Maintenance

Preventive maintenance is an important strategy for ensuring equipment reliability and reducing downtime.

Through regular inspections and maintenance, the availability and reliability of equipment can be significantly improved and downtime due to malfunctions can be reduced.

Haichen die casting machine through preventive maintenance, successfully reduce the failure rate of the mould and automatic injection components.

Die Casting Mould maintenance

Mould maintenance is equally important and includes cleaning, lubricating and inspecting mould surfaces for wear or damage.

These measures help to maintain the performance and extend the life of the mould.

Operator training and safety procedures

Ensure train operators are adequately on the operation of the machine, emergency procedures and how to properly handle molten metal and mould maintenance protocols.

In addition, operators must wear appropriate personal protective equipment (PPE) such as safety glasses, protective gloves, and fire resistant clothing.

Data analysis and troubleshooting

Machine operating data is analysed to identify potential failure modes and take preventive action.

For example, by analysing failure rates and fitness-for-purpose tests, replacement intervals for critical components can be determined to optimise maintenance schedules.

Equipment overhaul

For die casting machines that have been in operation for a long period of time, will require extensive repair work .

This usually involves disassembling, inspecting, repairing or replacing badly worn components and reassembling the equipment.

Cost control and economic efficiency

Maintenance work not only helps to ensure the normal operation of the equipment, but also improves economic efficiency.

Through scientific maintenance management, we can reduec the economic losses caused by equipment failure.

Haichen Die casting machine maintenance work covers from daily cleaning, lubrication to preventive maintenance, data analysis and large-scale equipment repair and other aspects, designed to ensure the efficient operation of the equipment and extend its service life.

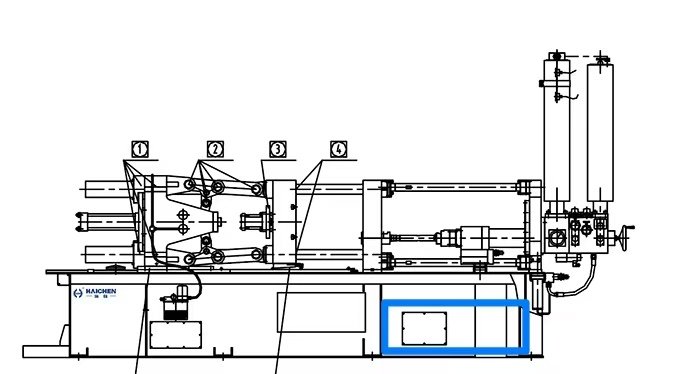

Die Casting Machine Maintenance of clamping unit

Die Casting Machine Maintenance of the clamping unit is an important part of ensuring proper operation and long service life of the machine.

Below are some detailed information about maintenance of clamping parts:

- Lubrication and inspection

- Inspection of fasteners and bolts

- Maintenance of hydraulic system

- Inspection of the electrical system

- Safe Operating Procedures

- Regular calibration and adjustment

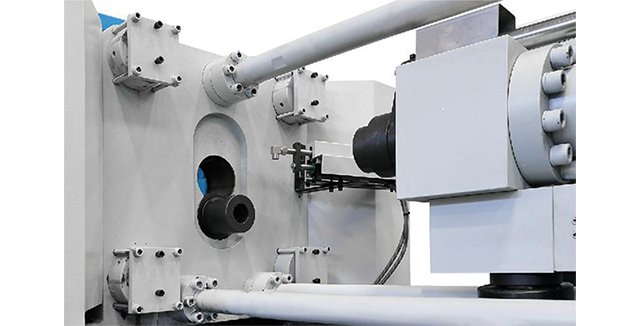

Lubrication and inspection

The clamping parts are prone to wear and damage due to long time reciprocating motion.

Therefore, regular lubrication of the clamping system is very important.

For example, we should to check the oil pressure in the hydraulic system regularly.

In order to ensure that the oil pressure is stable and avoid the problem of insufficient clamping force due to insufficient oil pressure.

In addition, it is also necessary to check whether the various rotating parts of the clamping unit are adequately lubricated to reduce wear and tear.

Inspection of fasteners and bolts

Fasteners such as bolts and screws using in clamping components need to be inspected periodically to ensure that they are not loose or damaged.

If they are found to be loose or damaged, they should be replaced promptly.

Maintenance of hydraulic system

The hydraulic system is an important part of the clamping component.

Therefore,should check the quality of hydraulic oil needs to regularly and deteriorate if needs to replace the hydraulic oil.

At the same time, clean the air filter, oil filter and oil cooler to keep the oil tank clean.

Inspection of the electrical system

Regularly check the voltage, current, solenoid valves and other components in the electrical system to ensure that they work properly.

If abnormal voltage or current is found,we should adjust or replace them in time.

Safe Operating Procedures

Before carrying out any maintenance work, you must make sure the equipment has been powered off and cut off the power supply to avoid accidental injury.

Regular calibration and adjustment

Adjustment of clamping force is essential to ensure product quality and productivity.

Therefore, the clamping force needs to be calibrated regularly and adjusted according to the actual situation.

Through the above measures, the clamping parts of Die Casting Machine can be effectively maintained, thus ensuring the stability and productivity of the equipment.

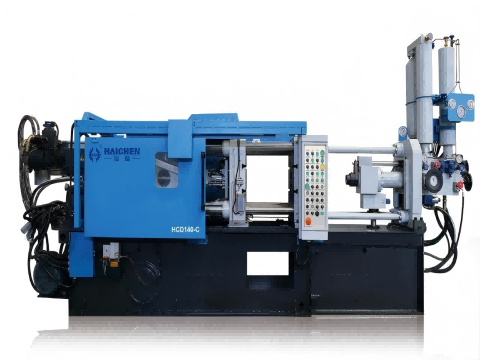

Haichen’s die-casting machines are of high quality and easy to maintain

- High quality production

- Easy maintenance

High quality production

Haichen’s die casting machines are designed and manufactured using advanced technology and strict standards.

For example, Haichen C-Series cold chamber die casting machines follow national and EU safety standards.

It is designed using Computer Aided Design (CAD) and Finite Element Analysis (FEA) techniques, and its hydraulic and electrical systems are supplied by renowned manufacturers in Europe, the United States and Japan.

These ensure the reliability and safety of our die casting equipment.

In addition, the Haichen H-series hot chamber die casting machine demonstrates its high performance and low cost for die casting of low melting point metals such as zinc and lead.

Easy maintenance:

Haichen die casting machines are designed with a focus on ease of operation and ease of maintenance.

For example, H series die casting machine with early warning machine maintenance function, convenient for users to carry out regular maintenance.

In addition, Haichen’s machines usually equipping with automated control systems and highly efficient servo systems, which reduce the need for manual intervention, thereby reducing maintenance difficulties.

Haichen’s die casting machines are not only of the highest quality, but are also for the user’s ease of use and maintenance in mind.