Aluminium die casting industry application includes automotive industry, aerospace, electronics industry and so on.

Aluminum Die Casting is an efficient and sustainable manufacturing process widely used in multiple industries. It has the characteristics of light weight, high mechanical strength, good thermal conductivity and electrical conductivity, making it an ideal choice for the manufacture of complex parts.

In the blog: Industry Application of Aluminium Die casting, we will discuss from

- Automotive industry

- Aerospace of Aluminium die casting industry application

- Electronics industry

- Consumer products

- Industrial equipment

Its main application areas include:

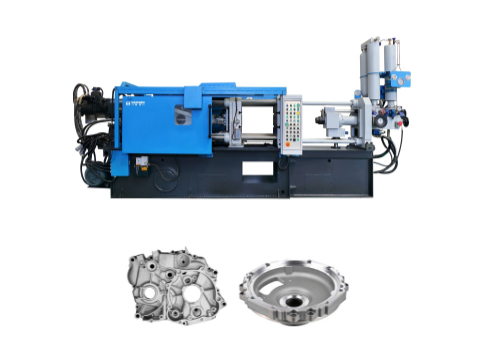

Automotive industry

Aluminum die casting plays an important role in the automotive industry. And it uses to produce lightweight components such as engine parts, transmission cases, steering housings, brake brackets, etc. to improve fuel efficiency and reduce emissions.

Engine Components of aluminium die casting industry application

including cylinder blocks, pistons, cylinder heads, valve covers, etc.

Aluminum die-casting’s high heat resistance and strength enable it to withstand high-temperature and high-pressure environments.

Transmission and Drivetrain

Transmission housings, clutch housings, gearboxes, etc. Aluminum die-casting can achieve complex geometries and integrate multiple components (e.g., combining a valve body and housing into a single casting), reducing assembly costs.

Chassis and suspension components

Hydraulic cylinders, engine mounts, steering system housings, and body structures. Lightweight design improves vehicle handling.

Wheels and brake components

Alloy wheels, brake drums, etc. Reducing unsprung mass optimizes driving performance.

Aerospace of Aluminium die casting industry application

Aluminum die casting uses in the aerospace field to manufacture key components. Such as high-strength aluminum parts for aircraft and spacecraft, which help improve fuel efficiency and reduce weight.

Structural Components

- Aircraft brackets, housings, airframes, and structural parts require high strength-to-weight ratios and complex geometries.

- Specific examples include cargo loading housings, distributor cap covers, and lighting fixture parts.

Powertrain and Fuel Systems

Engine piston heads, fuel system parts, and gearbox housings leverage the high-temperature resistance and dimensional accuracy of aluminum die-casting to ensure critical system reliability.

Thermal Management Components

Heat sinks and electronic enclosures rely on the excellent thermal conductivity of aluminum alloys to manage the temperature of aircraft electronic systems.

Electronics industry

In electronic products, aluminum die castings use to manufacture housings and protect sensitive components. Such as housings for mobile devices and computer equipment. And they are favorable for their good conductivity and heat dissipation properties.

Smartphones/Laptops

- Aluminum die-casting is used in housings, providing high strength, lightweight (reducing device weight), and aesthetics while protecting delicate internal components from shock and vibration.

- For Examples include metal frames in smartphones and laptop cases.

Cameras/Audio Equipment

- Camera components require high precision to ensure image quality, and the stability and durability of aluminum die-casting meet these requirements.

- Die-casting also enables compact designs and enhanced structural rigidity in audio equipment housings.

Other Equipment

These include electronic control panels, chassis, and decorative edge components.

Heat Sinks

- Aluminum’s excellent thermal conductivity (approximately 200 W/m·K) makes it an ideal material for heat sinks.

- Used in CPUs, power modules, LED lighting, and other applications, it effectively dissipates heat generated by electronic components, preventing overheating and extending device life.

Integrated heat dissipation design

The die-casting process allows heat sink fins or structures to be directly formed on the housing, improving heat dissipation efficiency.

Consumer products

Aluminum die castings widely use in consumer products such as kitchen utensils, furniture, and lighting equipment due to their lightweight and beautiful features.

Home Appliances and Household Goods: Aluminum die-casting is used to produce components (such as housings and structural members) for home appliances like washing machines, refrigerators, and air conditioners, as well as furniture accessories (such as door handles and window frames). Its lightweight and high-strength properties (wear and corrosion resistance) make it suitable for frequent use.

Consumer Electronics

Home Appliances and Household Goods

Aluminum die-casting is used to produce components (such as housings and structural members) for home appliances like washing machines, refrigerators, and air conditioners, as well as furniture accessories (such as door handles and window frames). Its lightweight and high-strength properties (wear and corrosion resistance) make it suitable for frequent use.

Consumer Electronics

- Housings and internal structural members for smartphones, tablets, and wearable devices.

Housings and heat dissipation components for smart home devices (such as smart speakers), VR devices, game consoles, and digital cameras. - Thermal management components (such as aluminium radiator ) utilize aluminum’s excellent thermal conductivity.

Power Tools

Housings and transmission components for tools like electric drills and electric saws require a balance between lightness and durability.

Sports Equipment

Lightweight designs enhance the user experience for bicycle frames, golf club heads, fishing reels, and other products.

Personal Care Devices

Precision structural components for products like electric shavers and beauty devices.

Core Advantages

- Lightweight and High Strength: Aluminum alloy’s high strength-to-weight ratio makes products more portable and durable.

- Design Flexibility: Complex geometries (such as curved surfaces and thin-walled structures) can be manufactured to meet the diverse design requirements of consumer products.

- Surface Finish Variety: Anodizing, sandblasting, electroplating, and painting processes are supported to enhance product aesthetics and functionality (e.g., anti-fingerprint and scratch resistance).

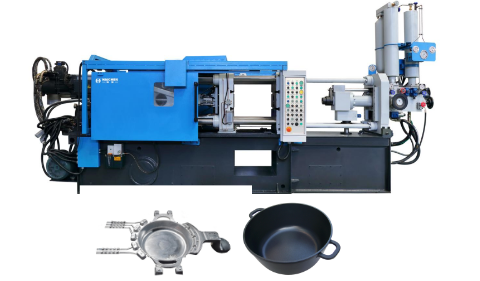

Haichen aluminium die casting industry application

For example, with aluminum alloy, Haichen produce high-output of aluminium cookware handles.

By design 12cav aluminum pan handle mould, to meet customer increasing production requirment.

Moreover, Haichen use aluminum alloys material to produce aluminum alloy pot, alumnium alloy pan. We can design replaceable pot, rechangable pan bottom moulds for same diameter with different bottom shape pans. Through Haichen adavanced aluminium die casting technology, and with Haichen high pressure cold chamber die casting machine.That can help save and reduce customer’s significant cost.

Haichen is a well-known manufacturer of high-pressure die casting (HPDC) machines, based in China. The company produces a wide range of die casting machines including cold chamber and hot chamber die casting machines. The machines cater to various industries, including automotive, electronics, home appliances, and more. Haiche

Industrial equipment

Aluminum die castings are used to manufacture industrial equipment such as pumps, valves, and compressors, and are widely used due to their high strength and corrosion resistance.

Key Mechanical Components

Aluminum die-casting is widely used in the manufacture of core components for industrial equipment, including:

Fluid control systems

pump bodies, valves, compressor housings, etc., leveraging aluminum’s corrosion resistance and high strength to withstand harsh operating conditions (such as chemical environments and high-pressure applications).

Power transmission components

Moving parts such as bearings, connecting rods, and pistons achieve lightweight designs through die-casting, reducing equipment energy consumption.

Structural support components

Motor housings and mechanical brackets provide rigid support while reducing overall weight.

Specialized Industrial Equipment

Heavy machinery parts cast using high-performance aluminum alloys such as B390 balance strength and wear resistance requirements, making them suitable for applications such as mining machinery and heavy machine tools.

Material Performance Advantages

- Lightweight: Aluminum has a density of only one-third that of steel, significantly reducing equipment movement energy consumption.

- Structural Strength: Die-cast parts boast a tensile strength exceeding 300 MPa, meeting the load-bearing requirements of industrial equipment.

- Environmental Adaptability: Corrosion resistance extends the service life of equipment in humid and chemical environments. Manufacturing Advantages

Complex Structure Integrated Molding

Enables the production of complex components with internal flow channels and reinforcement ribs, reducing welding and assembly steps (e.g., integrated valve bodies).

- Near-Net-Shaping Technology: Tolerances are controlled within ±0.1mm, reducing post-processing costs.

- Thin-Wall Molding Capability: Wall thicknesses as thin as 0.5mm are achieved, achieving a balance of lightweight and strength (e.g., thin-wall compressor housings).

Aluminum die casting has become one of the indispensable manufacturing technologies in modern industry due to its light weight, high precision and versatility, especially in the automotive industry and aerospace field.

Haichen die casting machine

At the same time, we produce both high pressure cold chamber die casting machine , hot chamber die casting machine and spare parts. They have durable and highly precise features.

Haichen also produce die casting machine auxiliary equipment. Such as conveyor, vacuum machine, mold temperature controller, industrial robot, sprayer and so on.

We supply cold chamber and hot chamber die casting machine spare parts.

Welcome contact us.