Key parameters select servo motor in die casting includes power, torque, precision, speed,control mode and so on.

While choosing a servo motor for a die casting machine, there are many factors that need consider such as: load inertia, effective torque, speed ratio and precision. Also with electrical parameters, a built-in braking function, communication ports, servo motor dimensions, as well as placement and installation.

In the die casting process, the accuracy of the servo motor is a key parameter. Selecting a high-precision servo motor can ensure the dimensional accuracy and surface quality of the die casting, thereby improving production efficiency and product quality. When selecting a servo motor, it is necessary to comprehensively consider parameters. Such as maximum speed, rated torque, moment of inertia and power output according to the actual application requirements.

Selecting a servo motor for a die-casting machine, power is a crucial parameter. It not only determines the motor’s output capacity, but also directly affects the system’s energy consumption.

The power of key parameters select servo motor in die casting

The power of a servo motor is one of the key parameters, including rated power, peak power and maximum power. Rated power refers to the maximum output power of the motor during normal operation, peak power refers to the maximum power that can be output in a short period of time, and maximum power is the limit power that the motor can withstand.

Power and Load Relationship

The servo motor’s power must meet the actual load requirements. If the power is too low, the motor will overload, which can damage the insulation or even burn out over time. If the power is too high, the motor’s capacity will be much higher than the actual load, resulting in a waste of resources.

The Relationship Between Power and Efficiency

- In die-casting machines, the power of a servo motor not only affects its control capabilities but also directly impacts the system’s energy consumption.

- Research has shown that adopting servo motor control technology can reduce energy consumption by 40%-70%, while also improving system response speed and stability.

- Therefore, when selecting a servo motor, prioritize models with high efficiency and low energy consumption.

Coordinating Power with Other Parameters

- The power selection of a servo motor must be coordinated with other parameters, such as torque, speed, and inertia.

- For example, Siemens servo motors typically have power ranging from a few hundred watts to several thousand watts. And the specific selection should be determined based on application requirements.

- Furthermore, the servo motor’s rated speed and torque must also match the power to ensure stable system operation.

Torque of key parameters

The torque of the servo motor directly affects its driving ability. In the die casting machine, the servo motor needs to provide sufficient torque to meet the needs of operations such as mold opening, mold closing, and metal pouring.

Definition and Importance of Torque

- Torque is the moment of force generated by a servo motor during rotation. It directly determines the load the motor can drive.

- In die-casting applications, the motor must overcome gravity, friction, and inertia during acceleration and deceleration. Therefore, accurately calculating the required torque is a prerequisite for selecting the appropriate motor.

Torque Calculation Methods

In practical applications, torque calculation typically includes the following aspects:

- Static load torque: This refers to constant external resistance, such as gravity and friction.

- Acceleration/deceleration torque: During starting or stopping, the motor needs to provide additional torque to accelerate or decelerate the load.

- Peak torque: In certain situations, such as sudden load changes or shocks, the motor needs to be able to withstand higher instantaneous torque.

The Relationship Between Torque and Speed

- The performance of a servo motor depends not only on its torque but also on its speed characteristics.

- It is noted that the servo motor’s torque-speed curve is an important factor in selecting a motor. This curve describes the maximum torque the motor can output at different speeds.

- In die-casting applications, the motor needs to provide high torque at low speeds to overcome inertia, while maintaining a certain torque at high speeds to maintain accuracy.

Servo Motor Rated Torque and Safety Margin

- When selecting a servo motor, a safety margin is generally required to ensure the motor does not overload during actual operation.

- For example, it is mentioned that the rated torque of a servo motor should be a certain percentage higher than the actual load torque to accommodate sudden load changes.

- Furthermore, it is also pointed out that the rated torque of a servo motor should be calculated based on the load structure, weight, and speed to ensure that its output torque meets the application requirements.

The relationship between a servo motor’s rated power and torque

- There’s a certain relationship between the rated power and torque of a servo motor.

- For example, the MEG series servo motor has a torque range of 50–1500 N·m, making it suitable for applications requiring high torque, such as die-casting machines.

- Furthermore, it’s also noted that the rated power of a servo motor should be matched to its output torque and speed to ensure the motor doesn’t overheat or become damaged during operation.

Precision of key parameters select servo motor in die casting

The precision of the servo motor is an important factor in ensuring the stability of the die casting process and product quality. High-precision servo motors can achieve fast response (about 5 milliseconds) and meet the needs of multi-stage pressure control.

Positioning Accuracy of key parameters select servo motor in die casting

A servo motor’s positioning accuracy is often determined by the resolution of its encoder. For example, a high-resolution encoder provides more precise position feedback, thereby improving the servo motor’s positioning accuracy.

Repeatability of key parameters select servo motor in die casting

A servo motor’s repeatability refers to its ability to maintain the same position over multiple runs. A servo motor with high repeatability ensures dimensional consistency across batches of die-cast parts.

Servo Motor Selection Criteria

When selecting a servo motor, consider the following key parameters:

- Maximum Speed: The maximum speed of a servo motor determines its performance at high speeds. For example, some servo motors have a maximum speed requirement of 1500 rpm or 3000 min⁻¹.

- Rated Torque: The rated torque of a servo motor determines the maximum load it can withstand. For example, some servo motors have a rated torque requirement of 1.8 N·m or 300 W.

- Moment of Inertia: The moment of inertia of a servo motor determines its performance during acceleration and deceleration. For example, some servo motors have a moment of inertia requirement of 3 kg·m² or 0.03 × 10⁻⁴ kg·m².

- Power Output: The power output of a servo motor determines the load it can drive. For example, some servo motors have a power output requirement of 1.8 kW or 300 W.

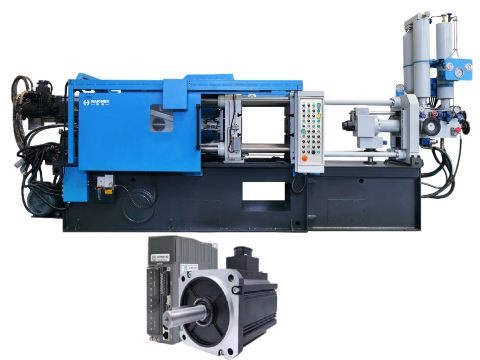

Application of Servo Motors in Die Casting

The application of servo motors in die casting is primarily reflected in the following aspects:

- Precise Control: Servos can precisely control parameters such as the die-casting machine’s opening and closing, injection speed, and pressure, thereby improving the dimensional accuracy and surface quality of die-cast parts.

- Energy Efficiency: Servos consume energy only when needed, making them more energy-efficient than traditional hydraulic systems. This not only reduces energy consumption but also improves production efficiency.

- Fast Response: Servos’ fast response speed allows for rapid adjustments to the die-casting machine’s operating status, thereby improving production efficiency.

Speed of key parameters select servo motor in die casting

The speed of the servo motor determines the efficiency of the die casting machine. The servo motor usually has a high speed (3000-5000 rpm), which can meet the needs of rapid prototyping.

Relationship between speed and current

The speed should be selected so that the required current does not exceed 100%. This means that when selecting the speed, the maximum current carrying capacity of the motor must be considered to avoid overloading.

The Impact of Speed on the Die Casting Process

- During the die casting process, injection speed and duration influence the filling pattern and casting properties.

- Faster injection speeds can produce thinner walls and cross-sections, but excessive speeds can lead to unstable flow of the molten metal within the mold cavity, causing splashing and eddy currents, which can affect casting quality.

- Therefore, when selecting speed, it is necessary to adjust the appropriate parameters based on the shape, size, and material of the casting.

Speed-torque relationship of key parameters select servo motor in die casting

- The speed-torque curve of a servo motor is one of the key factors in selecting a motor.

- This curve describes the motor’s capabilities and can be used to evaluate whether the motor meets the requirements based on the application needs.

- In the die casting process, rapid acceleration requires high torque output, so these factors need to be considered when selecting a motor.

Relationship between speed and load inertia

- Load inertia is an important consideration when selecting a servo motor. The larger the load inertia, the greater the torque required to accelerate and decelerate the motor.

- Therefore, when selecting the speed, it is necessary to ensure that the motor’s load inertia does not exceed 5 times the motor’s rotor inertia.

Control mode of of key parameters select servo motor in die casting

The control mode of the servo motor, such as position control, speed control, and force control, is critical to achieving precise operation. For example, in the die casting process, the servo motor is required to accurately control the opening and closing speed and position of the mold.

Position Control Mode

- In position control mode, the servo motor receives pulse signals to determine rotational angle or linear displacement.

- This mode is suitable for applications requiring precise position control, such as robotic arms and robot joints.

- In die casting, position control mode is ideal for moving the mold to a specific position for closing or opening operations.

Speed Control Mode: Key parameters select servo motor in die casting

- In speed control mode, the servo motor adjusts its speed based on the input voltage or current signal. This mode is suitable for applications where a constant speed must be maintained.

- Such as conveyors and the injection stage of an injection molding machine. In die casting, if you need to control mold closing speed or ejection speed, speed control mode can provide stable performance.

Torque Control Mode

- In torque control mode, the servo motor adjusts output torque by controlling the current.

- This mode is suitable for applications requiring precise force control, such as material stretching and winding equipment.

- In die casting, when constant clamping or ejection force is required, torque control mode ensures force stability.

Anti-interference ability of key parameters select servo motor in die casting

When the servo motor is running in a complex industrial environment, anti-interference ability is particularly important. Selecting a servo motor with high anti-interference ability can ensure the stability and reliability of the system.

The Importance of Anti-Interference Capability

- In industrial automation environments, servo drive systems are often exposed to various interference sources, including electromagnetic interference (EMI) and mechanical vibration.

- These interferences can affect the control accuracy and response speed of the servo motor, and even cause system failure.

- Therefore, servo drives must possess excellent anti-interference capabilities to ensure they can function properly in complex environments.

Specific manifestations of anti-interference capabilities

- Electromagnetic interference (EMI): In industrial environments, high-frequency currents, switching power supplies, and other devices generate electromagnetic interference. Servo motors and drives require filters, isolation transformers, and other measures to reduce the impact of this interference.

- Mechanical vibration: Mechanical vibration can affect the control accuracy of servo motors, especially at high speeds. To reduce the impact of vibration, vibration reduction designs or damping devices can be used.

- Power supply fluctuations: Fluctuations in the power supply voltage can also affect servo motor performance. Using a voltage stabilizer or uninterruptible power supply (UPS) can effectively address this issue.

Considerations When Selecting a Servo Motor

In addition to anti-interference capability, the following key parameters should also be considered when selecting a servo motor:

- Inertia Ratio: The servo motor’s inertia ratio (load inertia / motor inertia) must be within a reasonable range; otherwise, unstable control will occur.

- Torque and Speed: Select the appropriate torque and speed range based on the application requirements to ensure the servo motor can meet the load requirements.

- Encoder Type: A high-precision encoder (such as a 23-bit multi-turn absolute encoder) can improve the servo motor’s control accuracy.

- Communication Interface: Select a servo motor that supports standard communication protocols (such as CANopen, EtherCAT, and Profinet) to facilitate integration with host computers and other devices.