Shot sleeves and Plunger tips are key components in die-casting machines and you can purchase them from Haichen.

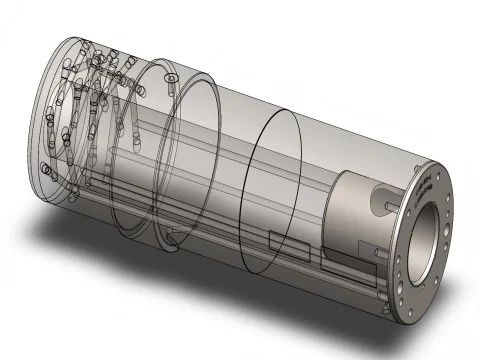

As a core component of die-casting machines, Shot sleeves main function is to inject molten metal from the plunger tip into the mold cavity.

It needs to maintain a stable temperature, prevent metal penetration, and extend its lifespan through a cooling system.

The materials are usually high-hardness steel such as H13 steel or special alloys such as surface-treated materials with ReCo treatment.

Plunger Tips design needs to take into account thermal expansion, sealing performance, wear resistance and cooling system.

For instance, beryllium copper alloys or copper-titanium alloys are widely used due to their high thermal conductivity and corrosion resistance.

Injection sleeves

Injection sleeves are important components in high-pressure die casting machines to protect the mold from the direct impact of molten metal.

High-performance alloy materials, such as tool steel, high-speed steel, or carbide materials, are typically used to make them, ensuring durability and resistance to wear.

When selecting an injection sleeve, you need to consider its heat resistance, dimensional stability, and compatibility with the metal being cast.

For example, some injection sleeves may have a ZrO2 coating on their surface to increase their durability in iron die casting operations.

Where to Find Them

Industrial Suppliers: Companies like Grainger, MSC Industrial Supply, or McMaster-Carr often carry these parts.

Specialized Die-Casting Suppliers: Look for suppliers that specialize in die-casting equipment, such as NADCA (North American Die Casting Association) members or companies like Dynacast or Buhler.

Online Marketplaces: Websites like Alibaba, eBay, or Amazon may have shot sleeves listed by third-party sellers.

Manufacturers: Contact manufacturers of die-casting machines (e.g., Toshiba, Husky, or LK Group) for OEM parts.

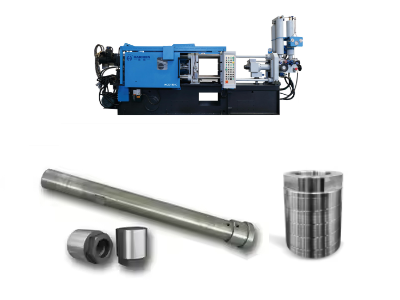

Plunger Tips

They attach to the plunger rod and push molten metal through the shot sleeve into the die cavity.

Plunger tips (die-casting machine punch tips) are key components in die-casting machines, used to inject molten metal into the mold cavity.

Their performance directly affects the quality of castings and production efficiency.

Its design needs to withstand high temperatures, high pressures and wear, and the materials should have high thermal conductivity, wear resistance and thermal stability.

Secondly, the punch tip needs to be customized according to the specific machine model, with diverse sizes and shapes to meet different application requirements.

Where to Find Them

- Die-Casting Equipment Suppliers: Companies like Die-Casting Automation or Castool specialize in these components.

- Custom Fabricators: Some companies can custom-make plunger tips to fit your specific machine.

- Online Platforms: Check Alibaba, ThomasNet, or other B2B platforms for suppliers.

- Machine Manufacturers: Reach out to the manufacturer of your die-casting machine for compatible plunger tips.

Things to Consider

Material: Manufacturers often make shot sleeves and plunger tips from high-quality tool steel or other heat-resistant alloys. Ensure the material matches your application.

Dimensions: Check the specifications (diameter, length, etc.) to ensure compatibility with your machine.

Brand Compatibility: Some parts are brand-specific, so verify compatibility with your die-casting machine model.

Haichen shot sleeves and plunger tips supplier

We specialize in manufacturing shot sleeves for die casting machines. Designed to meet the high demands of the die casting industry, our short sleeves provide reliable, efficient performance for all your die casting needs. We mainly supply cold chamber, hot chamber die casting machines and auxiliary equipments and spear parts.

Advantages of Haichen shot sleeves and plunger

- High-Quality Materials

- Compatibility with Haichen Machines

- Improved Casting Quality

High-Quality Materials

Haichen shot sleeves and plunger tips are typically made from premium materials like H13 tool steel or other heat-resistant alloys.

Durability: Resistant to wear and tear, even under high-pressure and high-temperature conditions.

Thermal Stability: Maintains structural integrity during repeated heating and cooling cycles.

Corrosion Resistance: Withstands exposure to molten metals like aluminum, zinc, and magnesium.

Compatibility with Haichen Machines

Haichen shot sleeves and plunger tips are specifically for Haichen die-casting machines, ensuring:

Optimal Performance: Seamless integration with the machine’s operating parameters.

Ease of Installation: Designed to fit perfectly, reducing setup time.

Improved Casting Quality

The precision and durability of Haichen components contribute to:

Better Metal Flow: Ensures consistent filling of the die cavity, reducing defects like porosity or incomplete fills.

Higher-Quality Castings: Produces parts with better surface finish and dimensional accuracy.