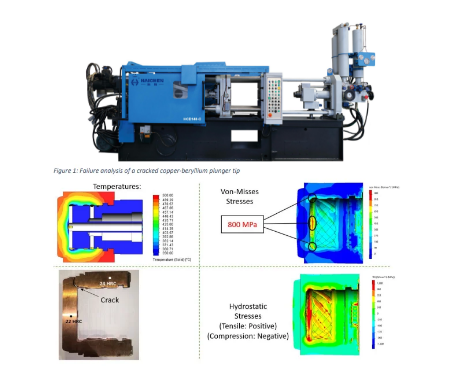

Die-casting machines enable the efficient and economical production of die-cast components. The most critical subsystem within a die-casting machine is its metal injection unit for die casting machine system. This system also incorporates the furnace, the mould clamping system, and various other control systems designed to regulate temperature and metal injection pressure.

The injection unit for die casting machine is one of its core components, mainly responsible for melting and injecting the liquid metal into the mold.

Main components of die casting machine injection unit

The injection unit of a die casting machine is a critical component responsible for injecting molten metal into the die cavity under high pressure. The main components of the injection unit include:

- Injection Cylinder for die casting machine

- Heating System of injection unit for die casting machine

- Nozzle

- Accumulator and Nitrogen Cylinder

- Servo Motor and Control System

- Hopper

- Cooling System

- Sensing Devices

Injection Cylinder for die casting machine

- The injection cylinder is a key component of the hydraulic system. It drives the plunger or screw to inject molten metal into the mold.

- Manufacturers typically make it from forged steel to withstand high system pressures.

Heating System of injection unit for die casting machine

- The heating system, often consisting of heater bands or electric heating circuits, is used to heat the barrel and maintain the required temperature for melting the material.

- Modern injection units may use solid-state relays and dual-barrel sensors for more stable and precise temperature control.

Nozzle

- The nozzle is located at the end of the barrel and is responsible for delivering the molten material into the mold cavity.

- It must be designed to withstand high pressures and temperatures.

Accumulator and Nitrogen Cylinder

- These components can boost injection pressure and ensure a more stable and powerful injection process.

- They help maintain consistent pressure and reduce pressure drop.

Servo Motor and Control System

- Servo motors can control the rotation and forward movement of the screw, providing high precision and responsiveness.

- Modern injection units are equipped with advanced control systems that allow real-time monitoring and adjustment of injection speed, pressure, and other parameters.

Hopper

- The hopper can feed raw material (usually in granule form) into the barrel. It ensures a steady supply of material for the injection process.

Cooling System

- The cooling system helps maintain the temperature of the injection unit and prevents overheating. It may include water channels or other cooling mechanisms.

Sensing Devices

- Sensors can monitor various parameters such as temperature, pressure, and screw position. These devices ensure the quality and consistency of the injection process.

These components work together to ensure the efficient and precise injection of molten material into the mold, resulting in high-quality die-cast parts.

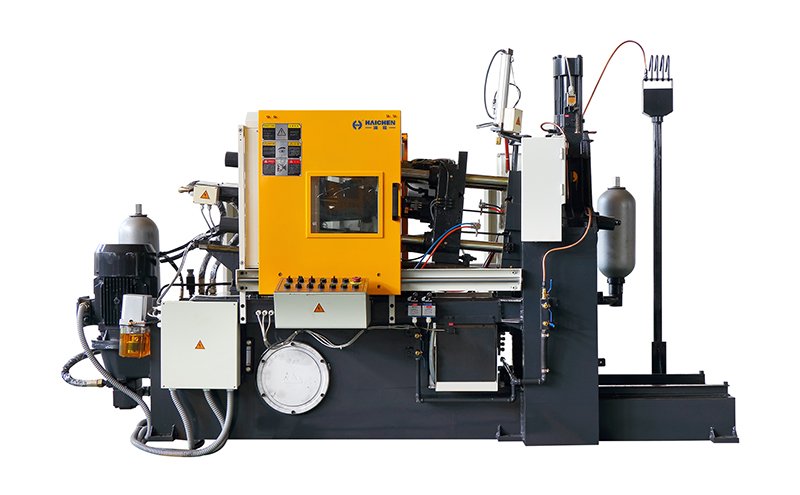

Haichen injection unit for die casting machine

Haichen is a reputable manufacturer of die casting machines, and the injection units are designed for high performance, precision, and reliability. We mainly supply cold chamber and hot chamber die casting machines and auxiliary equipments.

Key Features of Haichen Injection Units

High Injection Pressure and Speed

Designed to deliver high-pressure injection for precise filling of the die cavity, ensuring high-quality castings with fine details.

Energy Efficiency

Incorporates advanced hydraulic systems and energy-saving technologies to reduce power consumption.

Precision Control

Utilizes advanced PLC (Programmable Logic Controller) systems for precise control over injection speed, pressure, and timing.

Durability

Built with high-quality materials to withstand the harsh conditions of die casting, including high temperatures and pressures.

Versatility

Suitable for both cold chamber and hot chamber die casting processes, depending on the machine model.

User-Friendly Interface

Equipped with intuitive control panels for easy operation and monitoring of the injection process.